Heat preservation ageing device

A heat preservation and aging technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of high labor intensity, long natural aging time, low work efficiency, etc., and achieve simple structure, good practical application value and The effect of promoting value and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

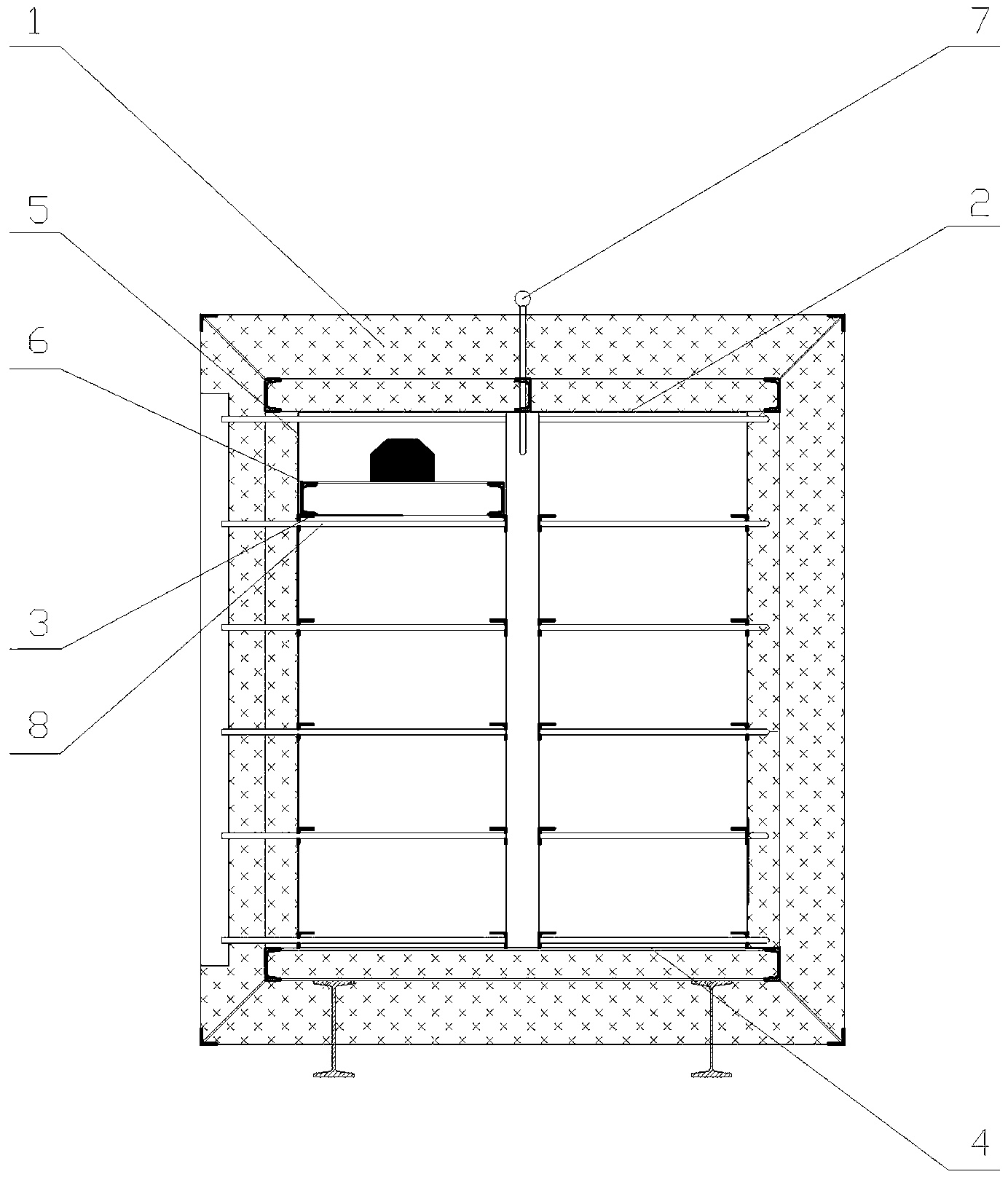

[0016] Such as figure 1 , figure 2 As shown, the heat preservation and aging device includes a large-scale charging container 1, and an aging bin is arranged in the large-scale charging container 1. 2 is provided with a temperature measuring instrument for testing the temperature in the aging chamber, and a plurality of aging containers 5 are placed on a plurality of aging chamber partitions 3, and each aging container 5 is provided with a temperature control heating device.

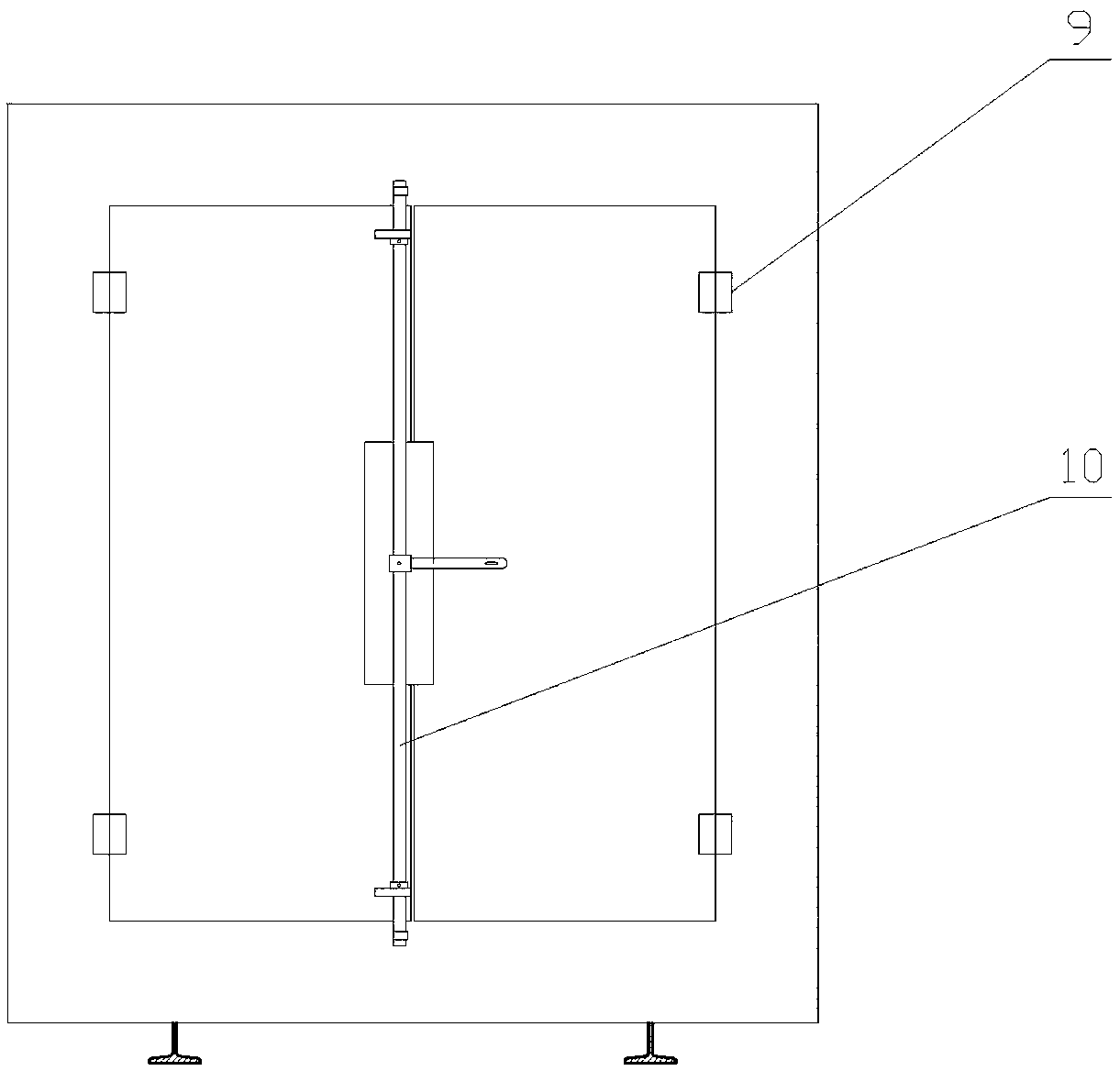

[0017] The aging container 5 is provided with a tray 6 for placing the product after deep processing; the temperature measuring instrument is a thermocouple 7, and the temperature control heating device is an electric heating tube 8; A tightly sealed compartment lock 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com