Erecting method for last three-span box girders in railway bridging

A box girder, the final technology, applied in the field of bridge construction, can solve the problems of no increase in erection speed, high labor intensity, and reduced efficiency of box girder erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

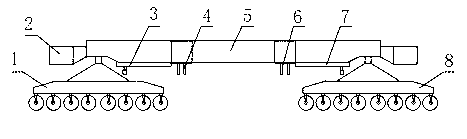

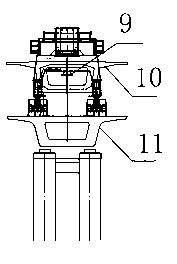

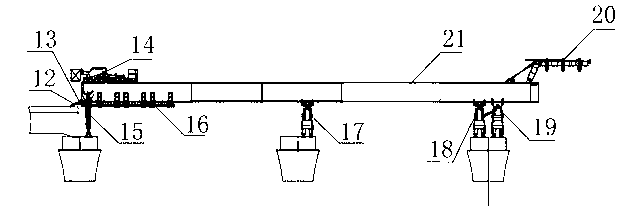

[0024] The invention specifically relates to a method for erecting the last three-hole box girder in railway bridge erection. The equipment used in the method is a frame-transporting integrated bridge erecting machine, which is composed of a lifting beam machine and a guide The beam machine consists of two parts, as attached Figure 1-3 shown. The beam lifting machine is mainly composed of: front wheel set 8, rear wheel set 1, saddle beam, power system, hydraulic system, hoisting system 2, main beam, buffer oil cylinder, steering oil cylinder, and pallet 9; among them, the hoisting system 2 Including rear auxiliary winch 3, rear spreader 4, main beam 5, front spreader 6, front auxiliary winch 7; beam guide machine mainly consists of: carrying beam trolley 14, shifting platform 16, mobile ladder, rear outrigger 15. The front roller support leg 19, the middle roller support leg 18, the rear roller support leg 17, the guide beam 21, the guide beam tie rod 12, and the overlapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com