Pneumatic designing method of counter rotating compressor combining pumping of boundary layer

A technology of aerodynamic design and boundary layer, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the difficulties in the design of suction pipes, the failure to fully utilize the load capacity of the suction stage of the boundary layer, and the decrease in blade strength, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

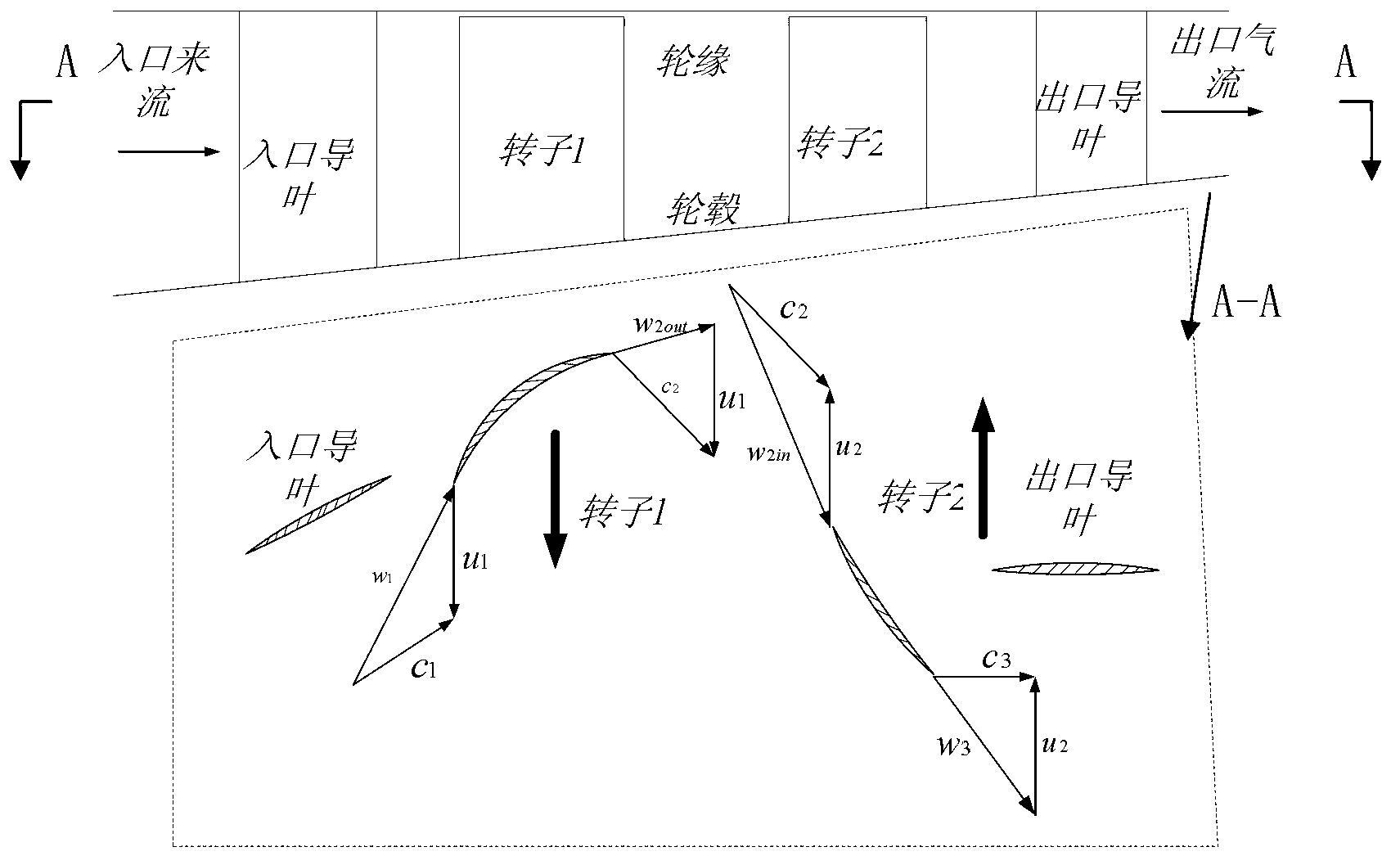

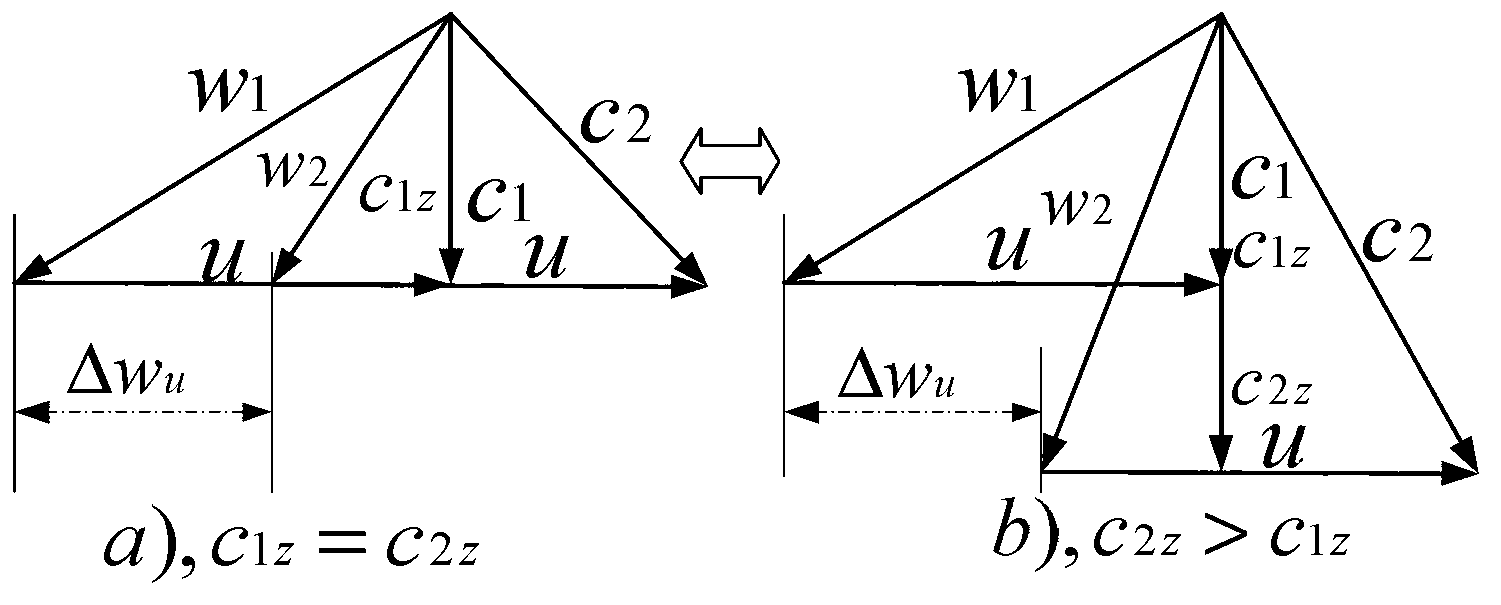

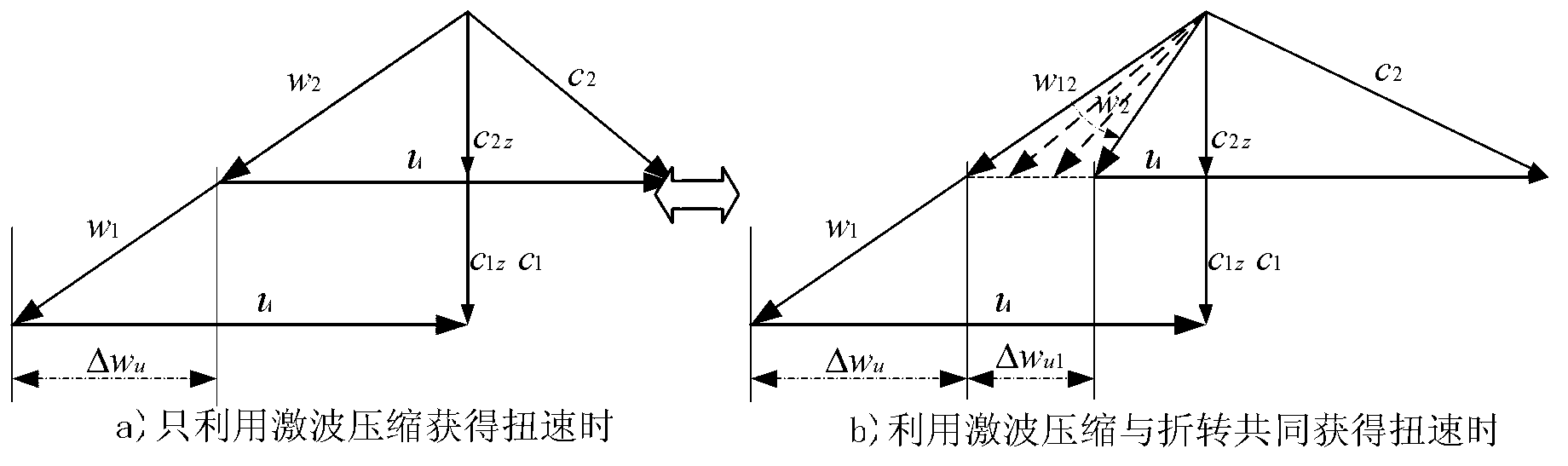

[0058] In actual design, according to the performance requirements of the engine as a whole. Usually the following parameters are given. Design speed, including the first row of rotor speed u 1 and the rotor speed u in the second column 2 ;Design load, including the first row of rotor design load Δw u1With the design load of the second column rotor Δ2w u2 ;Axial speed at the rotor inlet of the first column c 1z , the axial velocity c of the stator exit of the second column 5z . In addition, for the first row of rotors, the pre-swirl can be given according to its inlet Mach number requirements, but when the first row of rotors is already transonic or supersonic under the premise of axial air intake, usually direct axial air intake, that is For the first-stage moving blade, the inlet velocity triangle is known, namely u 1 , c 1 ,w 1 are known. Therefore the realization step of this invention is as follows:

[0059] Step 1. Using the high-efficiency and high-load rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com