Plate type solar light condensation system with invariable focal point elevation angle

A technology of concentrating system and elevation angle, which is applied in the field of solar energy applications, can solve the problems of difficulty in meeting the requirements of reliability and cost, few stable applications and promotion, and increased cost, so as to facilitate the utilization of concentrating light and heat energy transmission, and improve stability. performance, reliability, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

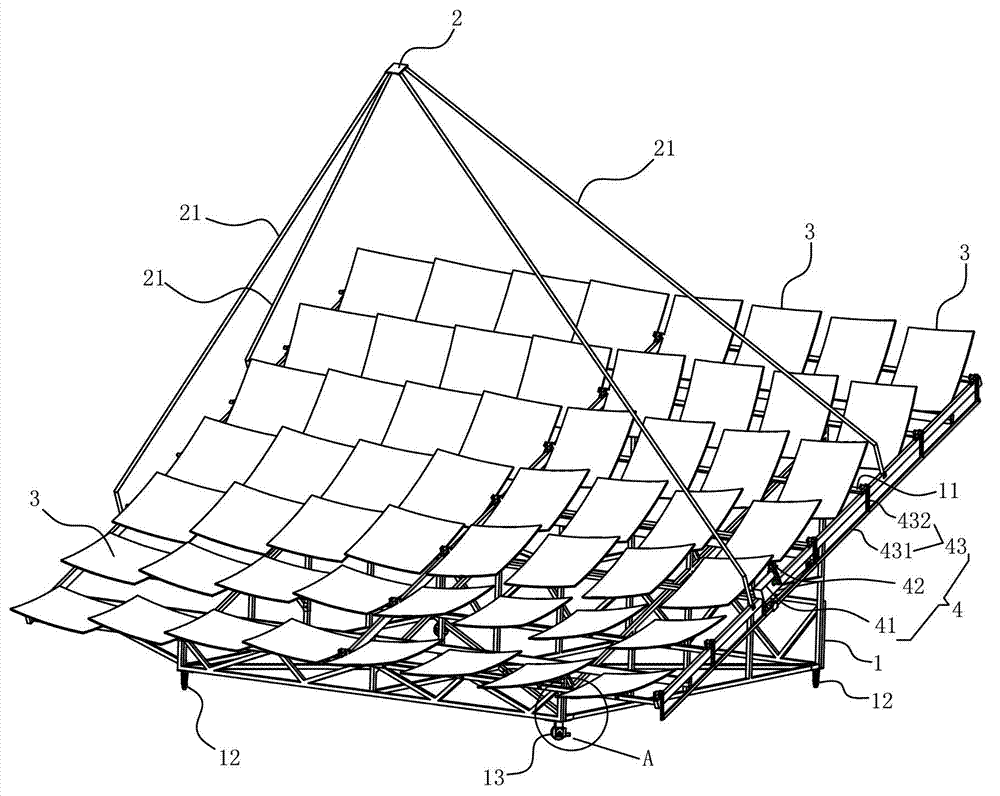

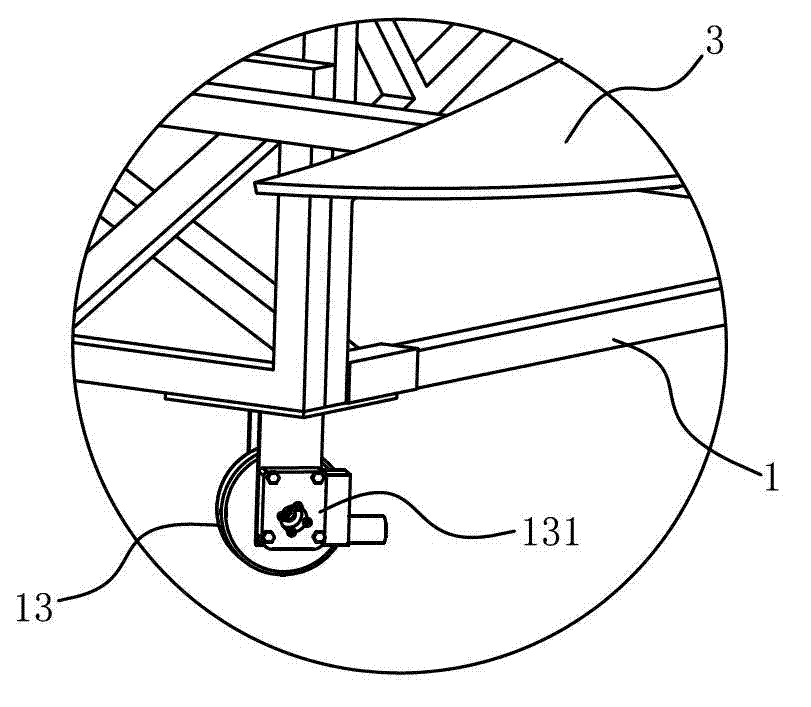

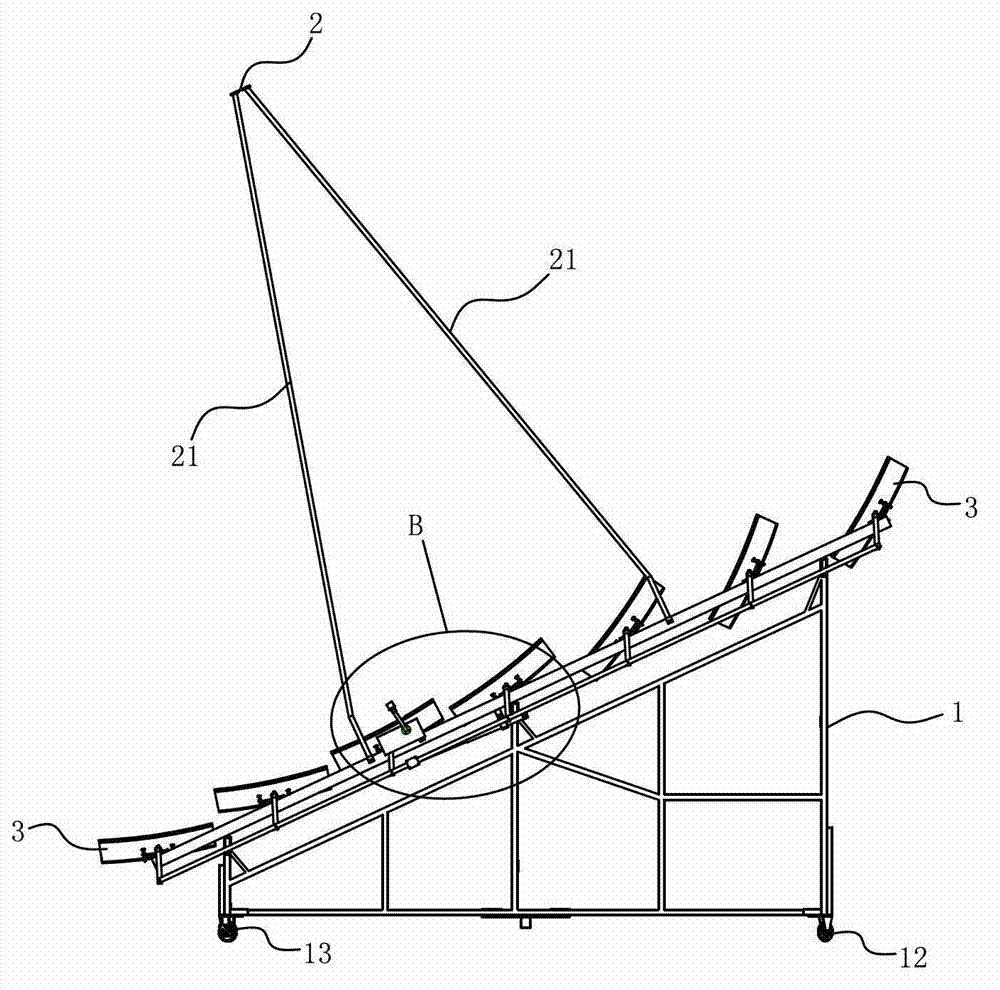

[0039] see Figure 1-4 Shown, a kind of dish type solar concentrating system with constant elevation angle of focus, it comprises: a fixed elevation angle support 1 and the focusing focus receiving module 2 installed on the fixed elevation angle support 1, a plurality of dish reflectors 3, the sun Tracking control mechanism4.

[0040] The fixed elevation angle support 1 is used as the carrier of the whole dish solar concentrating system, and the fixed elevation angle support 1 is provided with a plurality of lens rotating shafts 11, and the lens rotating shaft 11 is provided with a plurality of bearing seats 111, wherein each Mounting positions for the dish mirrors 3 are provided in the supporting seats 111 .

[0041] The focusing point receiving module 2 is positioned on the fixed elevation angle bracket 1 through the support bar 21, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com