Unaided-eye three-dimensional (3D) light emitting diode (LED) display screen and manufacturing technique thereof

A 3D LED and production process technology, applied in the field of naked-eye 3D LED display and its production process, can solve the problems of unfavorable alignment between LED display and 3D grating, and achieve better display effect, high production efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

[0018] The production process of the preferred embodiment of the present invention to produce naked-eye 3D LED display screens includes the following steps:

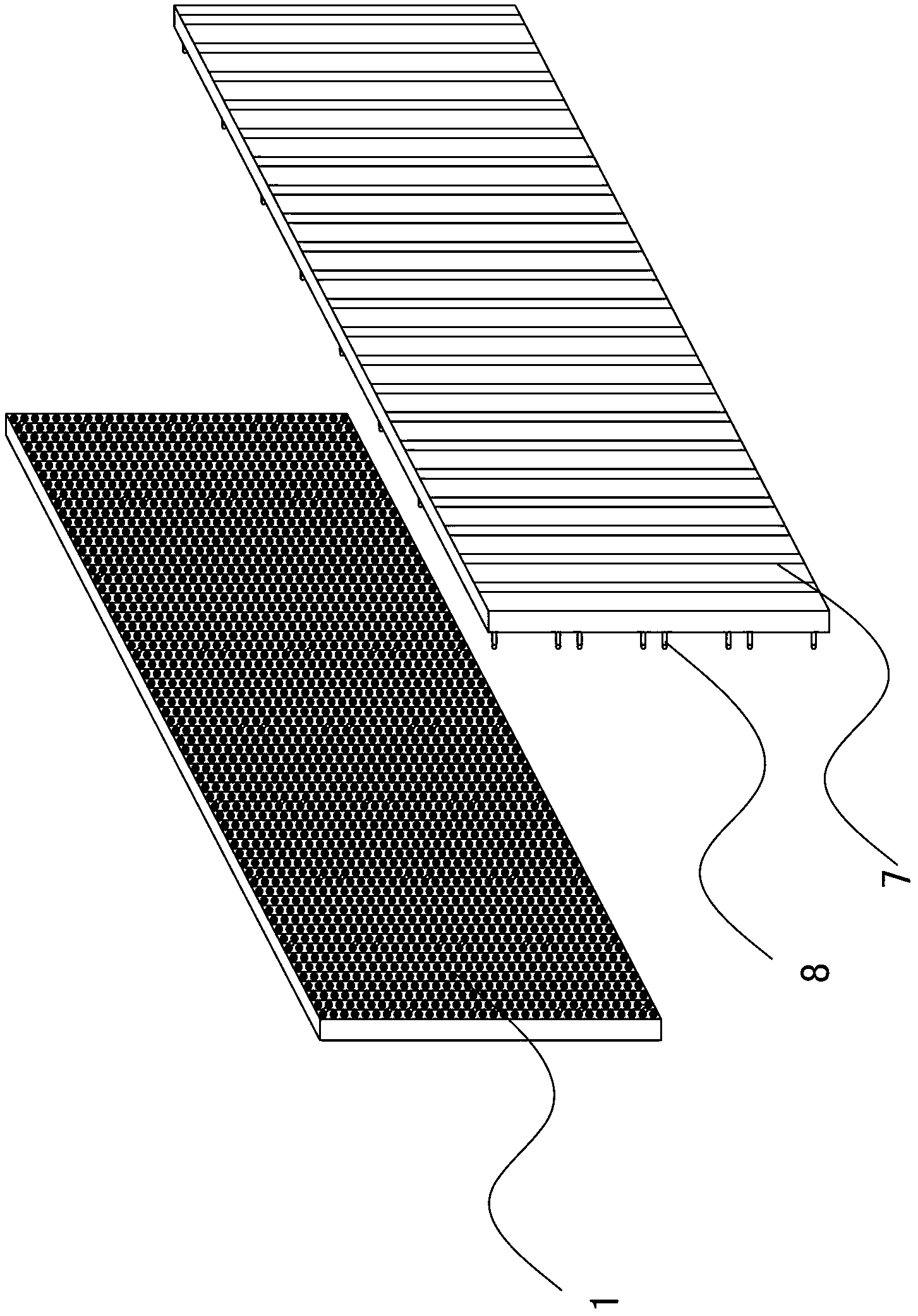

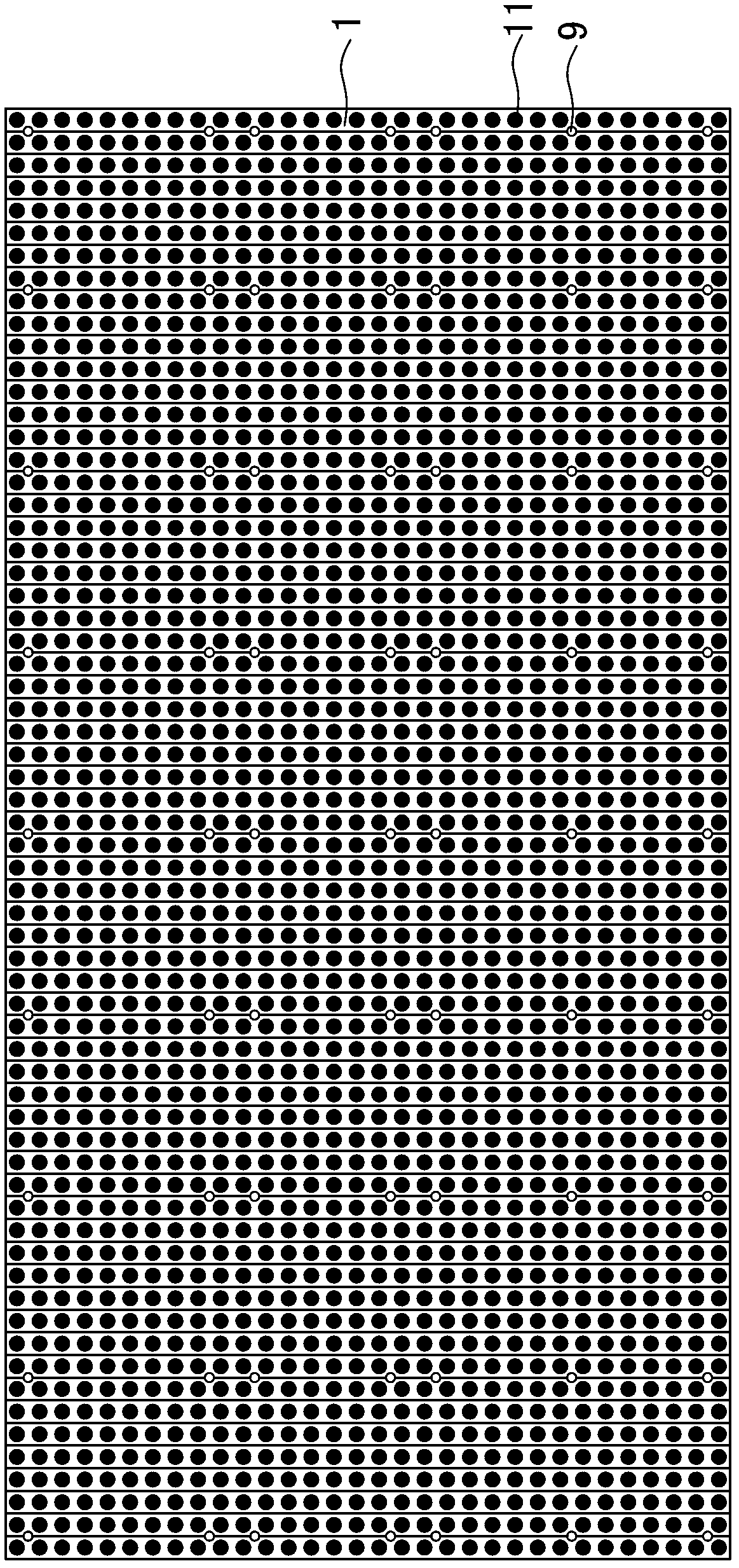

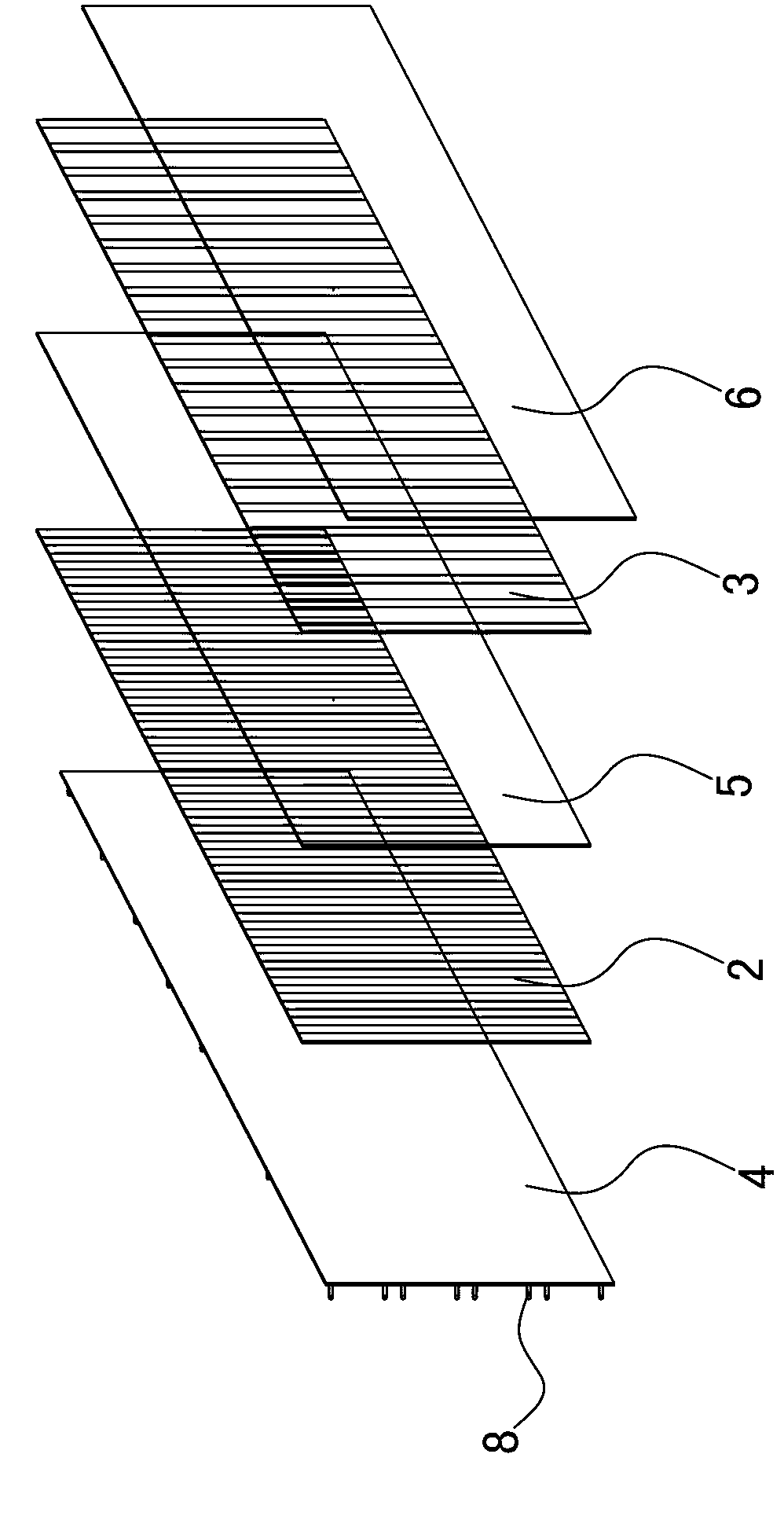

[0019] (1) Prepare materials, provide a set of LED display module 1, two pieces of first grating plate 2 and second grating plate 3 made of film material, first acrylic plate 4, second acrylic plate 5, third acrylic Plate 6, wherein the first grating plate 2 and the second grating plate 3 are slit grating plates separated by black and white lines, and the first acrylic plate 4, the second acrylic plate 5, and the third acrylic plate 6 are polyacrylic methyl acrylate (PMMA for short) board;

[0020] (2) To make a transparent grating panel, the first grating plate 2, the second grating plate 3, the first acrylic plate 4, the second acrylic plate 5, and the third acrylic plate 6 in step (1) are sequentially covered wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com