Carbon dioxide (CO2) welding machine automatic grounding device

An automatic grounding and welding technology, applied in contact parts, connecting contact materials, etc., can solve the problems of reducing the work efficiency of employees, the stability of the body quality, affecting the welding adjustment operation of the body, etc., to improve work efficiency, product quality, structure and so on. Simple, coordination-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

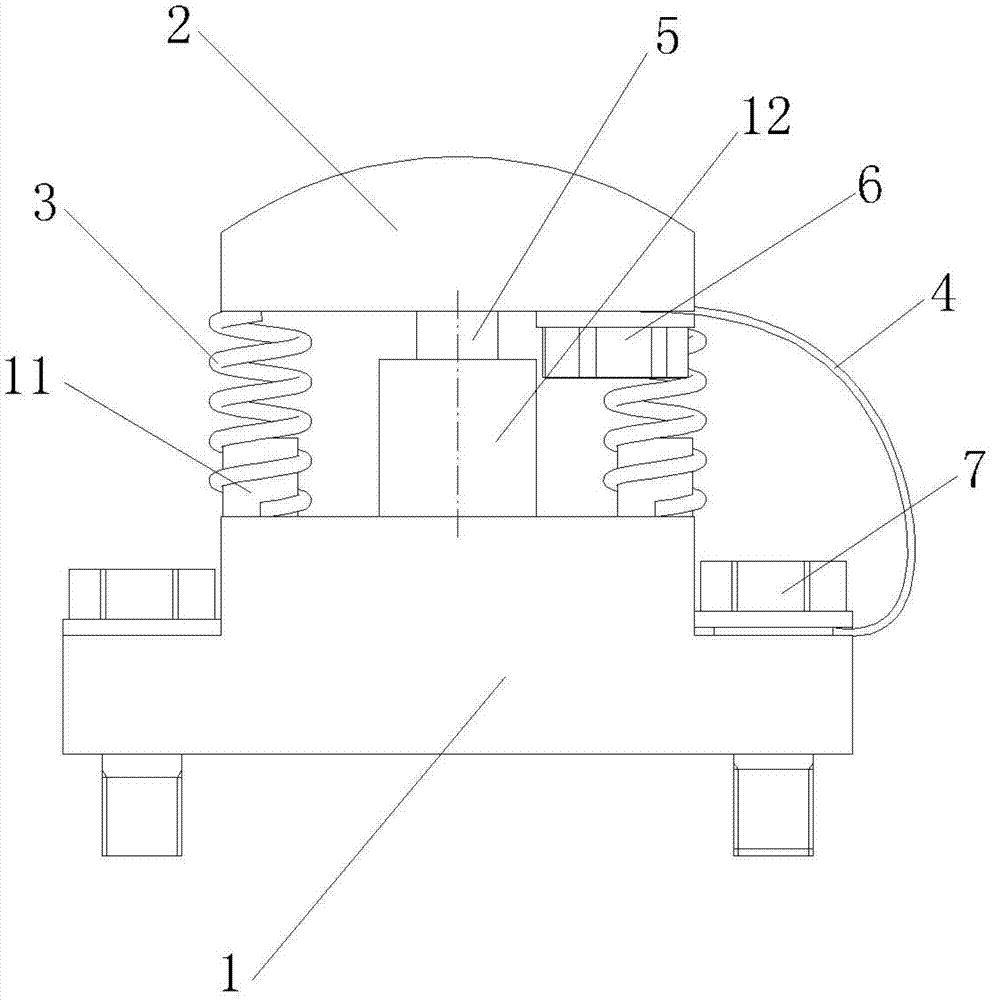

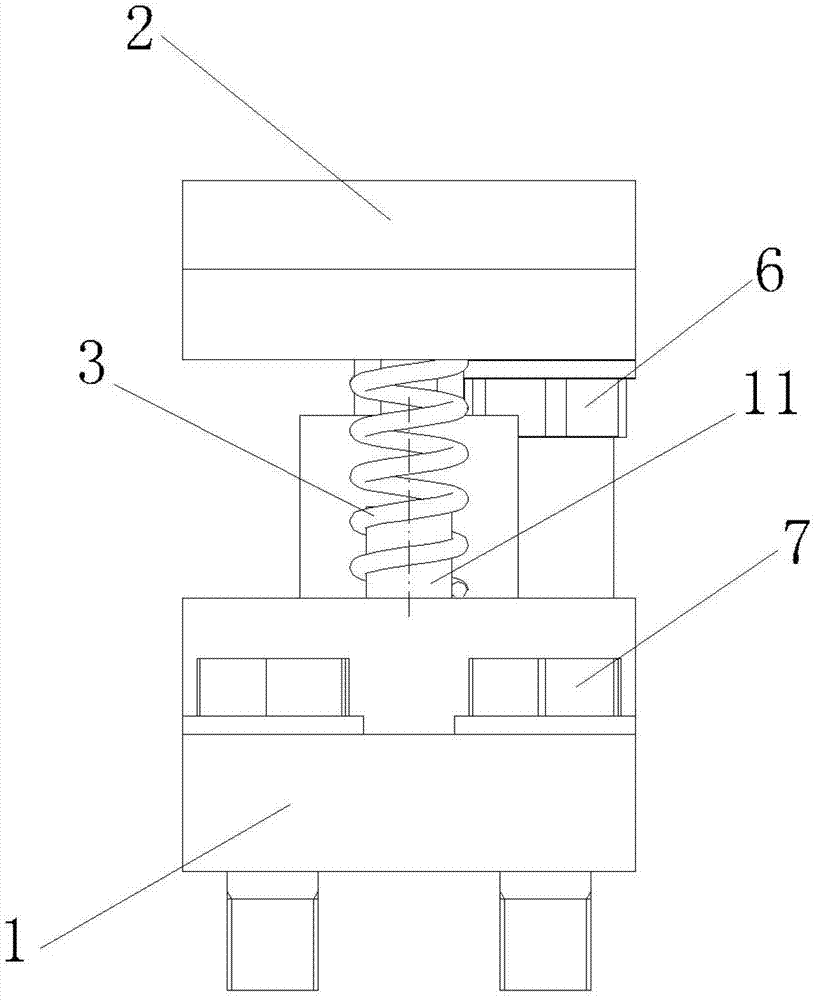

[0025] This embodiment provides a CO 2 Welding machine automatic grounding device, please refer to figure 1 with figure 2 , the CO 2 The automatic grounding device of the welding machine includes: a base 1, a conductive copper plate 2, a spring 3 and a copper wire row 4, and the base 1 is used for installing other components of the device. The spring 3 is arranged on the base 1, and the conductive copper plate 2 is arranged on the spring 3, that is, the lower end of the spring 3 abuts against the upper surface of the base 1, and the upper end of the spring 3 withstands the lower end surface of the conductive copper plate 2, so that the conductive copper plate 2 It can move up and down along with the expansion and contraction of the spring 3. Both ends of the copper wire row 4 are respectively connected to the conductive copper plate 2 and the base 1 , thus forming a path between the base 1 and the conductive copper plate 2 . Preferably, the first end of the copper wire ro...

Embodiment 2

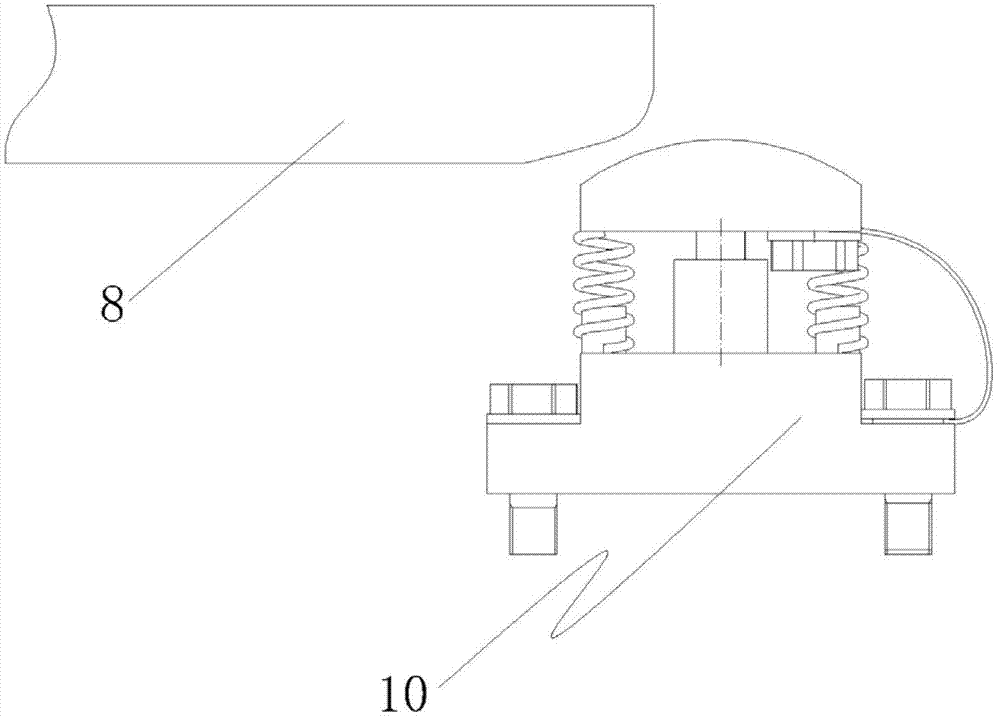

[0032] The embodiment of the present invention provides a CO 2 Welding machine automatic grounding device, please refer to Figure 1 to Figure 4 , this embodiment reflects the working state of the device. The CO 2 The automatic grounding device 10 of the welding machine is installed on the corresponding fixed bracket of the roller bed used by the base bolt 7, and the CO 2 The negative ground wire of the input terminal of the welding machine is connected to the base 1 through the base bolt 7, and the CO 2 The automatic grounding device 10 of the welding machine is installed at the lower end of the adjustment line conveying roller bed, and the upper surface of the conductive copper plate 2 is slightly higher than the conveying roller of the roller bed. Like this, when the slide skid 8 that is loaded with body-in-white advances, slide skid 8 front parts and CO 2 The automatic grounding device 10 of the welding machine contacts and forms a welding circuit, because in this CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com