Arc stabilizer for underwater wet welding

A technology for wet welding and arc stabilization, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as droplet instability, and achieve the effects of simple and flexible use, enhanced effect, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

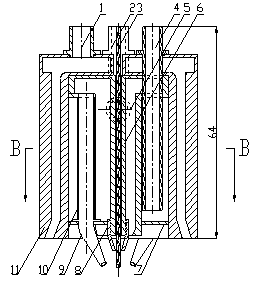

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

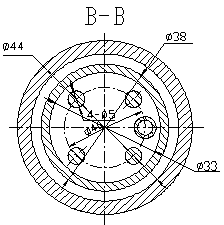

[0016] Such as figure 1 , shown in 2, the present invention consists of high-pressure air intake pipe (1), shielding gas intake pipe (2), welding wire (3),

[0017] Cooling water inlet pipe (4), cooling water outlet pipe (5), conductive rod (6), baffle (7), welding nozzle (8), iron core (9), excitation coil (10), protective cover ( 11) Composition. The whole arc stabilizing device is a cylindrical structure covered by a protective cover (11), which is completely sealed except for external air and water inlet and outlet pipes. The protective cover (11) is an insulating material and is insulated from the contact tip. The inside of the protective cover (11) is a high-pressure gas pipeline, which is fed through the upper high-pressure gas inlet pipe. The center is a conductive rod (6), and the welding wire (7) passes through the middle of the conductive rod (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com