Measuring and welding device in metal mask assembling machine and moving mechanism thereof

A metal mask and motion mechanism technology, applied in the field of mechanical devices, can solve the problems of affecting production efficiency and complex operation steps of OLED masks, so as to save machine space, meet the needs of multiple functional applications, and reduce cumbersomeness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

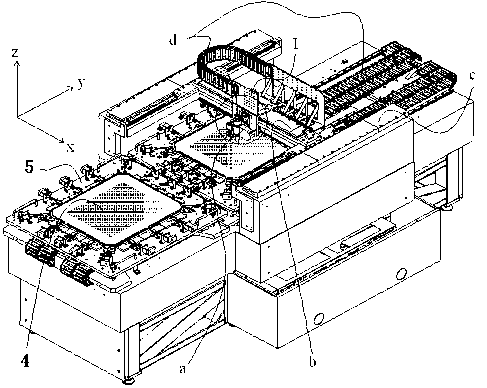

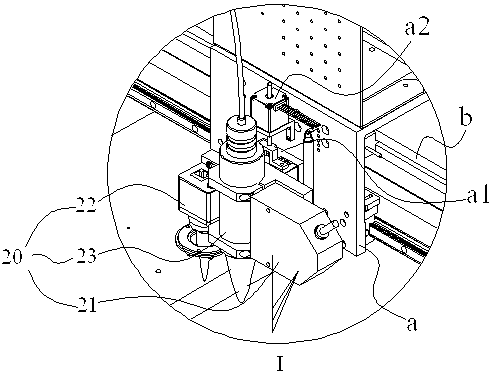

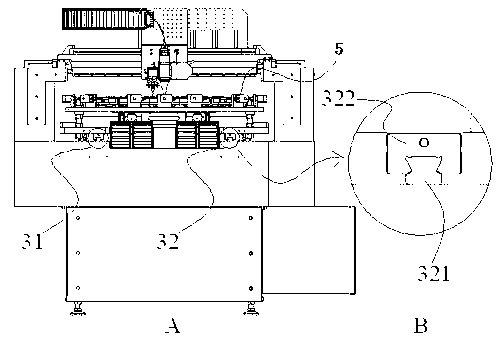

[0022] figure 1 Shown is a schematic diagram of the overall structure of the metal mask assembly machine, and the movement mechanism therein includes: a movement mechanism in the x-axis direction, a movement mechanism in the y-axis direction, and a movement mechanism in the z-axis direction. The measuring and welding device can move freely in a certain space through the cooperation of the moving mechanism in the three directions of x, y and z.

[0023] Such as figure 1 As indicated by the coordinate axes, the directions of x, y, and z axes are perpendicular to each other, which are not limited to a specific direction in space, but relatively speaking, the directions of x and y axes are two directions perpendicular to each other in the horizontal direction, and the directions of z axis The direction is the vertical direction; the movement directions of the x-axis direction movement mechanism, the y-axis direction movement mechanism and the z-axis direction movement mechanism o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com