Solid-liquid separation sewage treatment device

A sewage treatment device and solid-liquid separation technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Level processing technical advantages and other issues to achieve the effects of reducing work interference, facilitating digestion, and stabilizing process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

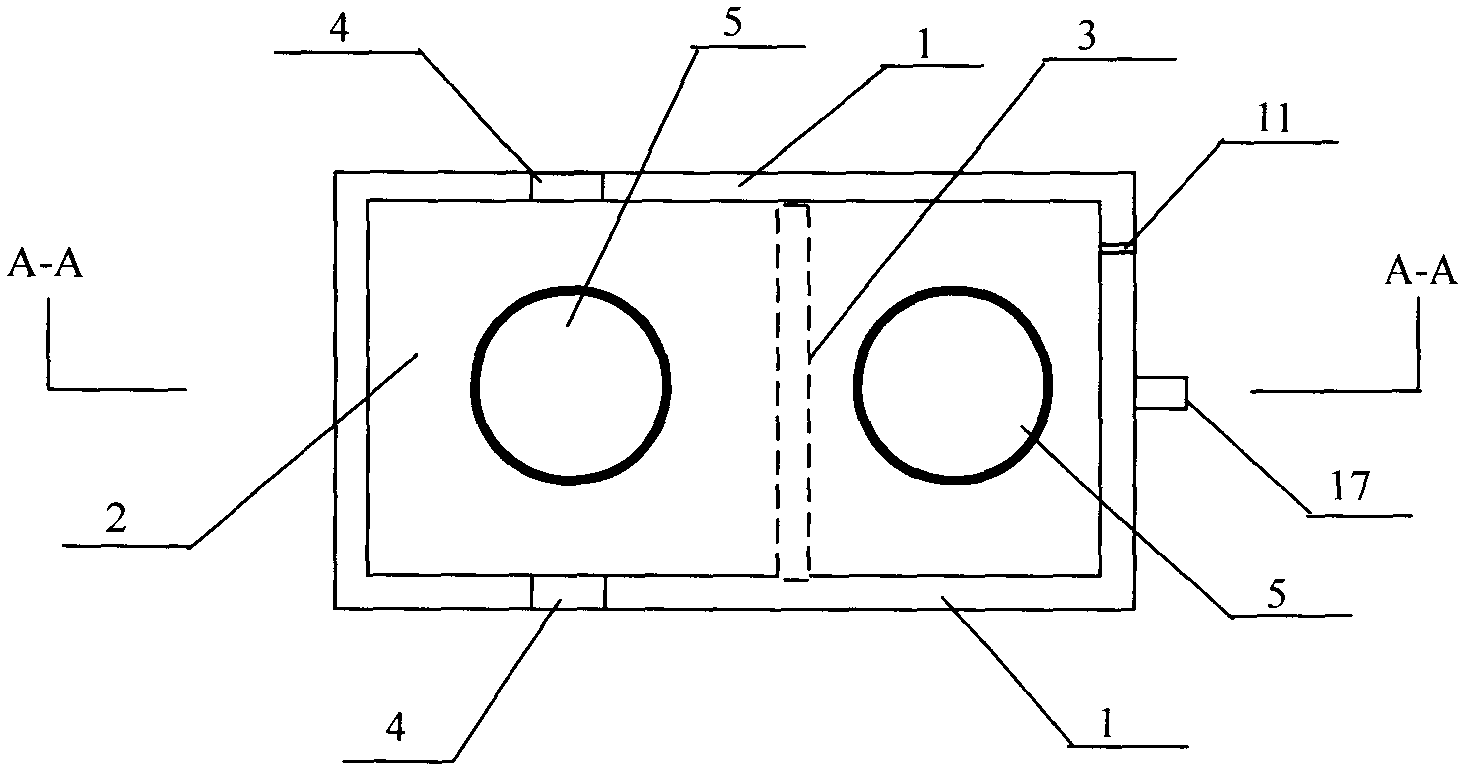

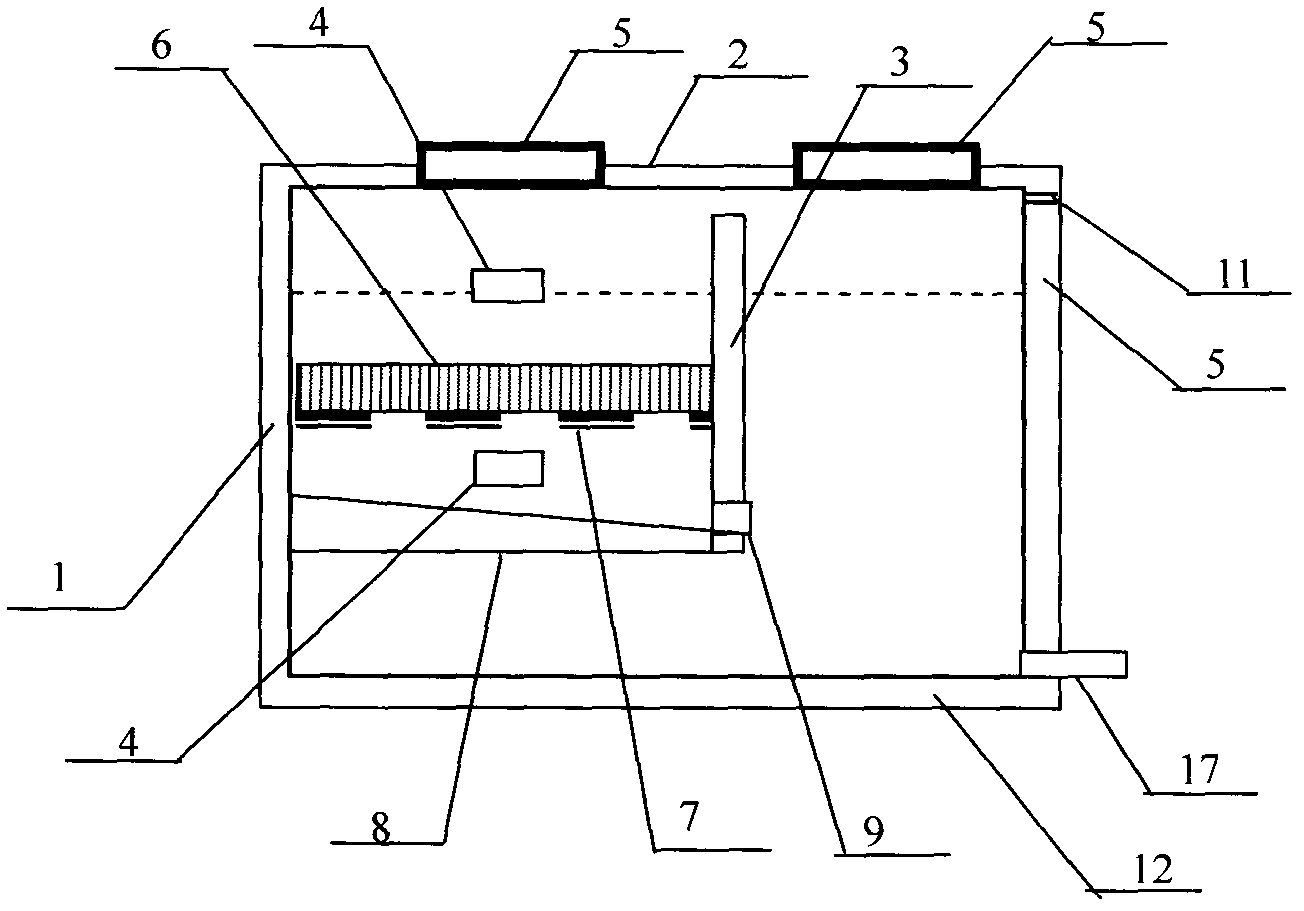

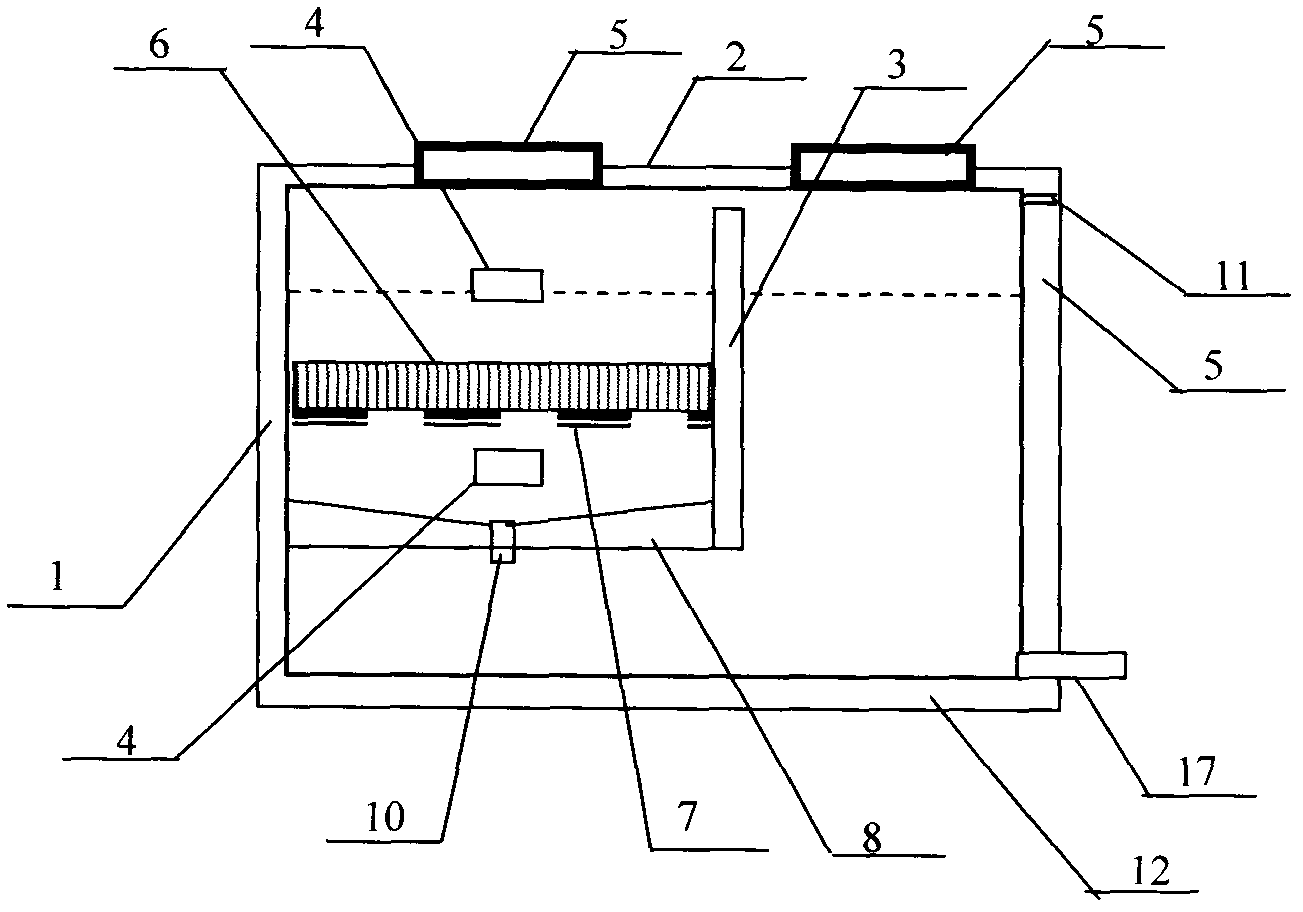

[0024] Such as figure 1 , 3 , 4, 5, 6, and 7 shown embodiment one is that a front end has a settling tank 18 in series with three solid-liquid separation treatment unit sewage treatment units, each solid-liquid separation treatment unit is separated by muddy water inside the bottom plate 8 and muddy water The partition side wall plate 3 is divided into a sewage treatment space and a sludge treatment space. In the sewage treatment space, there is a sewage interception device 6. At least one air-blocking sedimentation pipe 10 is installed on the mud-water separation bottom plate 8. The upper surface slope of the mud-water separation bottom plate 8 To the upper opening 13 of the air-blocking sedimentation pipe 10, the lower opening 14 of the air-blocking sedimentation pipe 10 is lower than the bottom of the mud-water separation bottom plate 8, and the side walls of the corresponding two sides of the sewage treatment space are respectively provided with water holes 4, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com