Multi-functional liquid analysis system and method

A liquid analysis, multi-functional technology, applied in the analysis of materials, material analysis by optical means, and analysis by chemical reaction of materials, etc., can solve the problems of poor portability, difficult maintenance, low reliability, etc. The cost of inspection, simple and efficient maintenance, and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

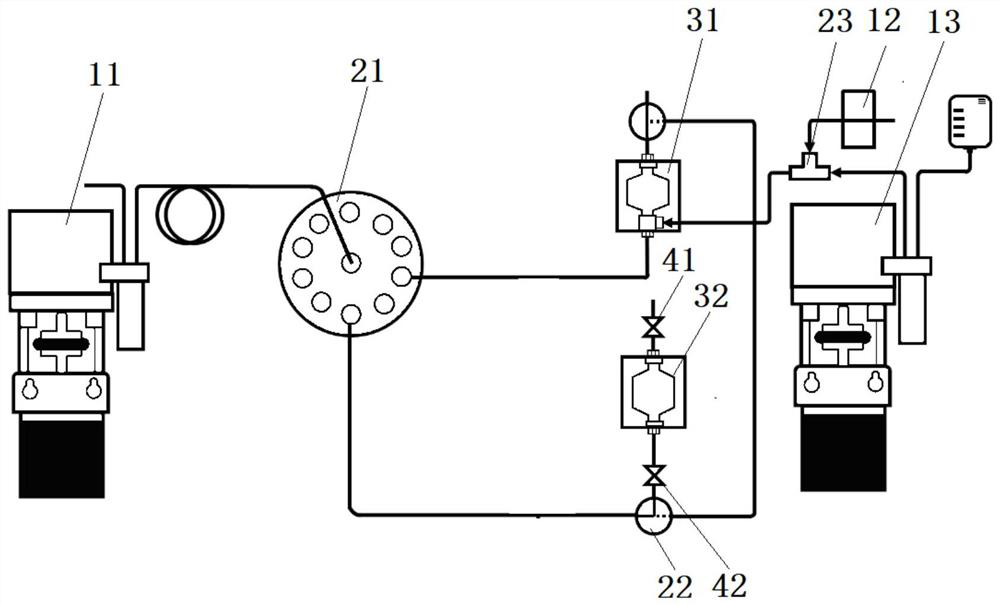

[0030] figure 1 A schematic structural view of the multifunctional liquid analysis system of the embodiment of the present invention is schematically given, as figure 1 As shown, the multifunctional liquid analysis system includes:

[0031] the first pump 11, the second pump 12 and the third pump 13;

[0032] The first switching module 21, such as a multi-channel selector valve, is used to selectively connect the outlet of the first pump 11 to the inlet of the first container 31 and the inlet of the second container 32;

[0033] The first container 31 and the second container 32, the first container 31 and the second container 32 have an inlet and an outlet respectively; the outlets of the second pump 12 and the third pump 13 communicate with the inlet of the first container 31 respectively , the outlet of the first container 31 communicates with the inlet of the second container 32;

[0034] A first valve 41 and a second valve 42, the first valve 41 is arranged upstream of...

Embodiment 2

[0053] An application example of the multifunctional liquid analysis system and method according to Embodiment 1 of the present invention in water quality testing.

[0054] In this application example, if figure 1 As shown, the lower side of the first container 31 and the second container 32 has an inlet, and the upper side has an outlet; the first switching module 21 is a multi-channel selector valve, and the second switching module 22 and the third switching module 23 both adopt Electromagnetic three-way valve, the outlet of the third switching module 23 communicates with the lower inlet of the first container 31; the first pipeline communicates with the upper outlet of the second container 32 and the first valve 41, and the second pipeline communicates with the second container 32 The lower side inlet and the second valve 42, the sealing method between the first pipeline and the upper side outlet of the second container is the same as the sealing method between the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com