Environment-friendly corrugated board

A corrugated board, environmentally friendly technology, applied in the field of corrugated paper manufacturing, can solve problems such as unfavorable sustainable development, poor impact resistance, white pollution, etc., and achieve the effects of light weight, easy transportation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

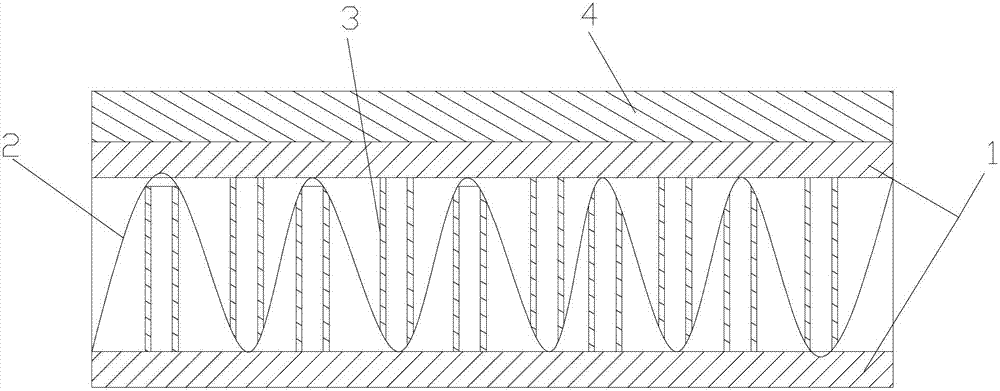

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. like figure 1 As shown, an environment-friendly corrugated cardboard includes two face paper layers 1 and a core paper layer 2 placed between the face paper layers. The core paper layer is mainly composed of corrugated cardboard, and between the corrugated cardboard There are support columns 3 for supporting the two layers of paper. The support columns are paper tubes with holes in the axial direction, and the paper tubes are vertically fixed between the corrugated cardboards. They can be arranged at intervals in order to save materials. A buffer layer 4 is laid outside the at least one face paper layer. In the present invention, the buffer layer is a layer of sponge bonded outside the face paper layer, and the thickness of the sponge is 10mm-20mm. In order to make the present invention waterproof, a wax ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com