Combined interlayer pulley vertical hinged lead door and corresponding planer steel plate track

A combined type and pulley technology, which is applied to the special equipment of doors/windows, door leaves, windows/doors, etc., can solve the problems of patients trapped in the machine room, difficult to rescue, easy to damage the motor, etc., to achieve smooth, stable and light operation, It is not easy to fail, and the surface is smooth and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

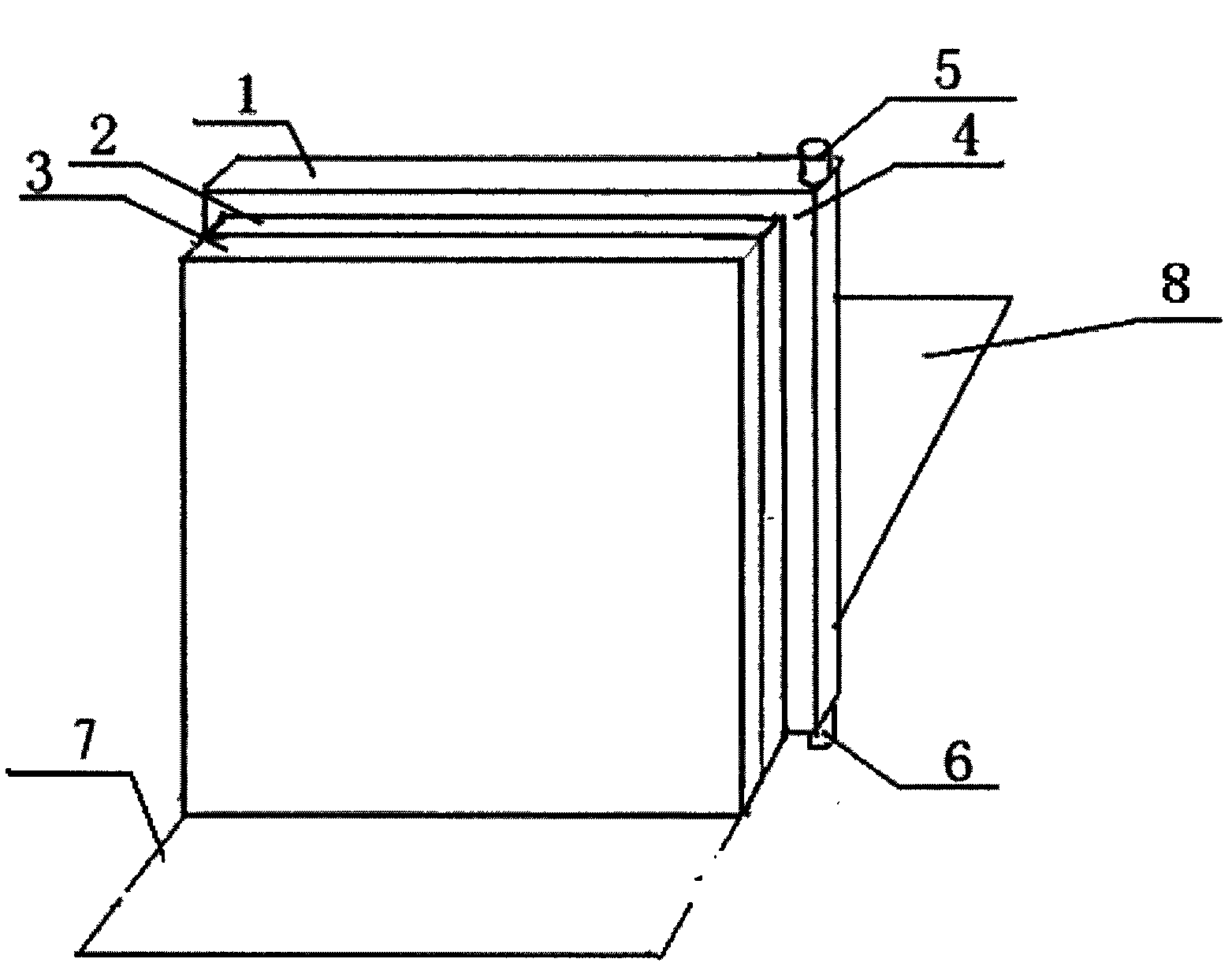

[0013] figure 1 Embodiment 1 shown: the covering layer (1) of the lead door is 2-10 cm higher than the embedding layer (3) and the steel connecting frame layer (2), and is also 2-10 cm wider than the embedding layer and the steel connecting frame layer, so When the embedded layer and the steel connecting frame layer are embedded in the doorway, the covering layer can block the rays leaking between the doorway and the embedded layer.

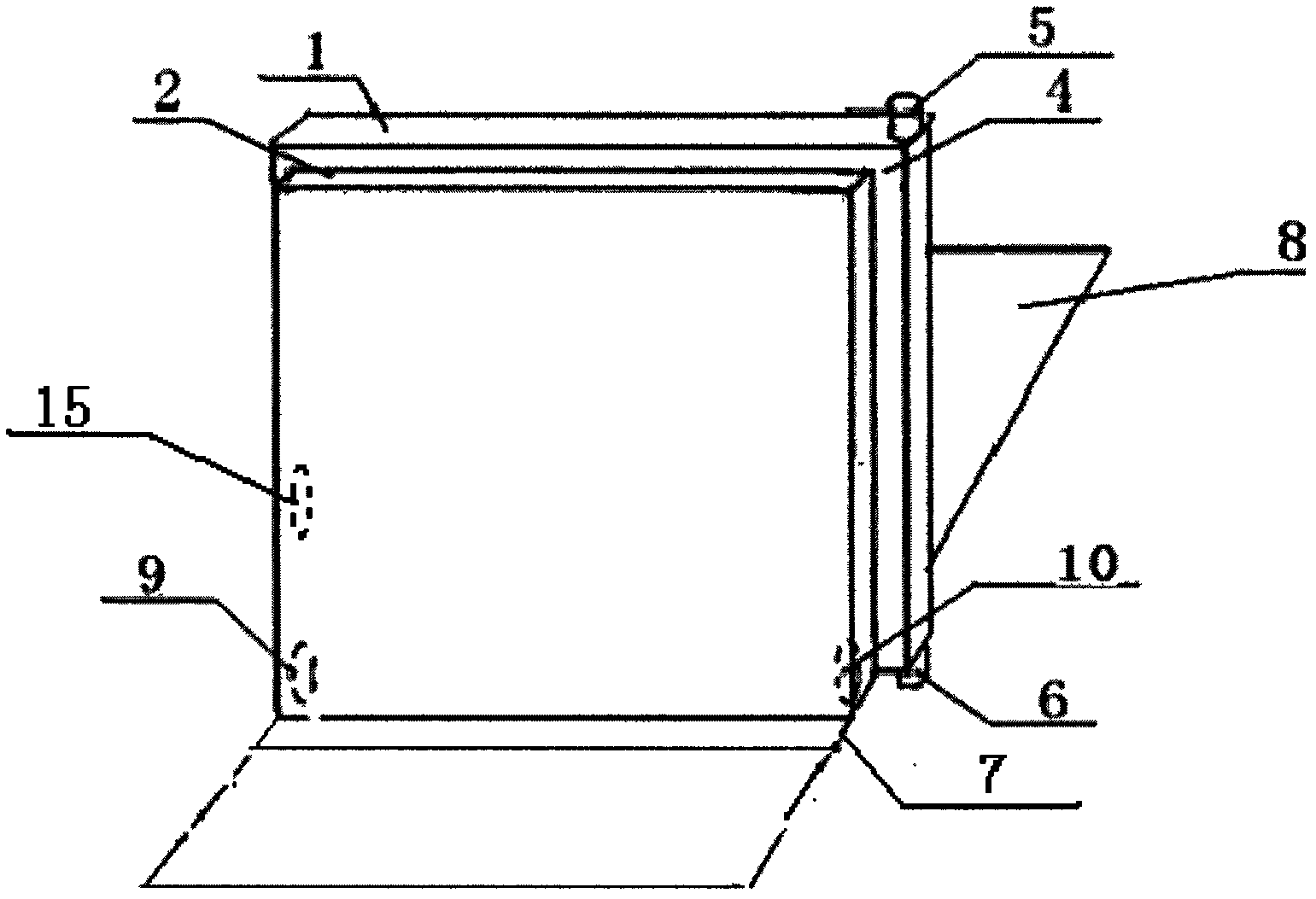

[0014] figure 2 Example 2 is shown: the pulley (9) on the moving side of the bottom of the steel connecting frame and the vertical movement of the inner and outer surfaces of the jaw, the power system (15) above the pulley, and the pulley (10) on the side of the door shaft and the vertical movement of the inner and outer surfaces of the jaw .

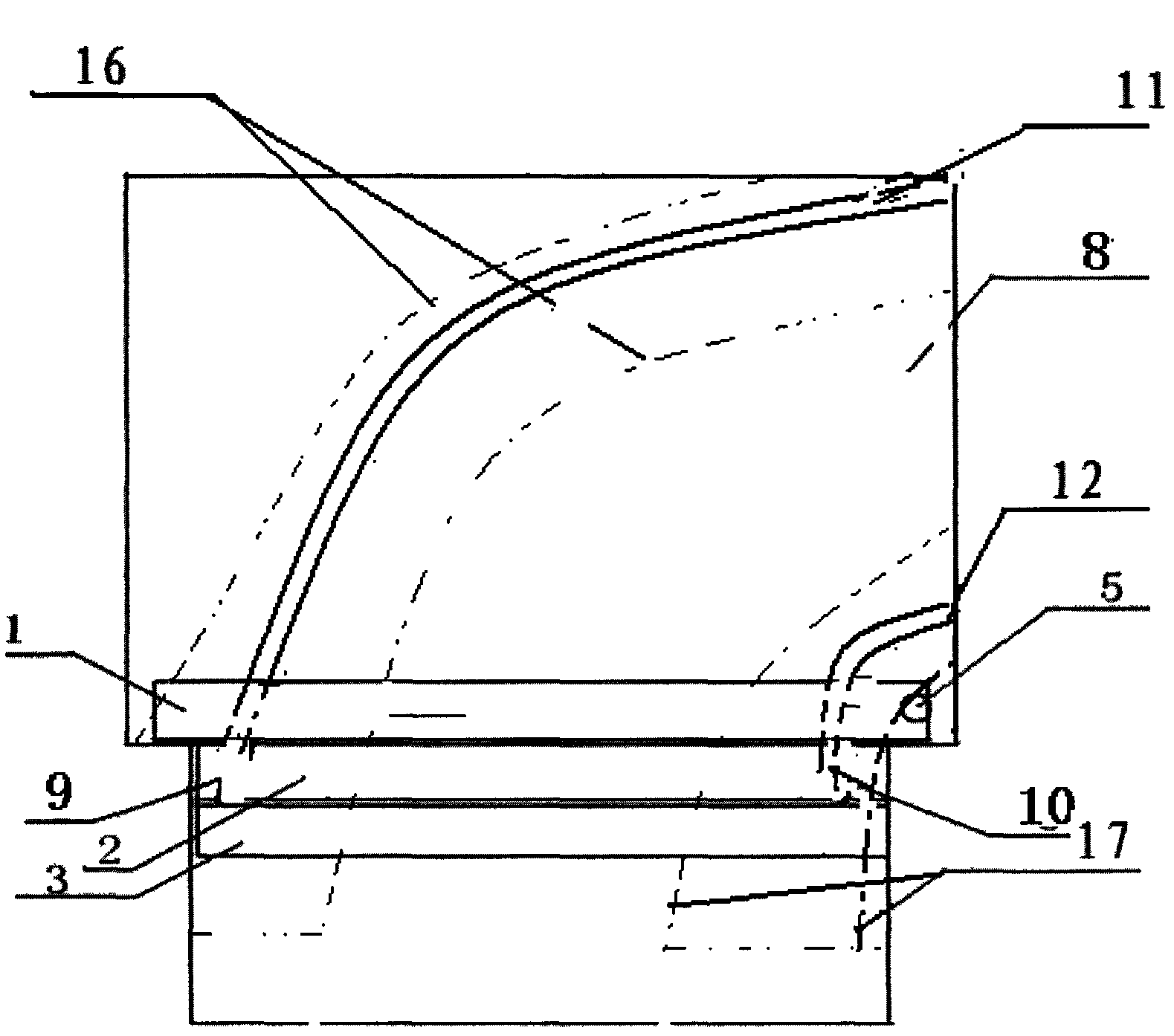

[0015] image 3 , Figure 4 Shown embodiment 3: when the jaw moves, the track of the motion of the pulley and the plane steel plate track laid along the track: represent the side pulley track of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com