Vertical packaging machine for emulsion explosives

A vertical packaging machine, the technology of emulsion explosives, applied in the direction of ammunition, ammunition storage, weapon accessories, etc., can solve the problems of low packaging work efficiency, high cost, high equipment maintenance cost, and achieve simple packaging process, high work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

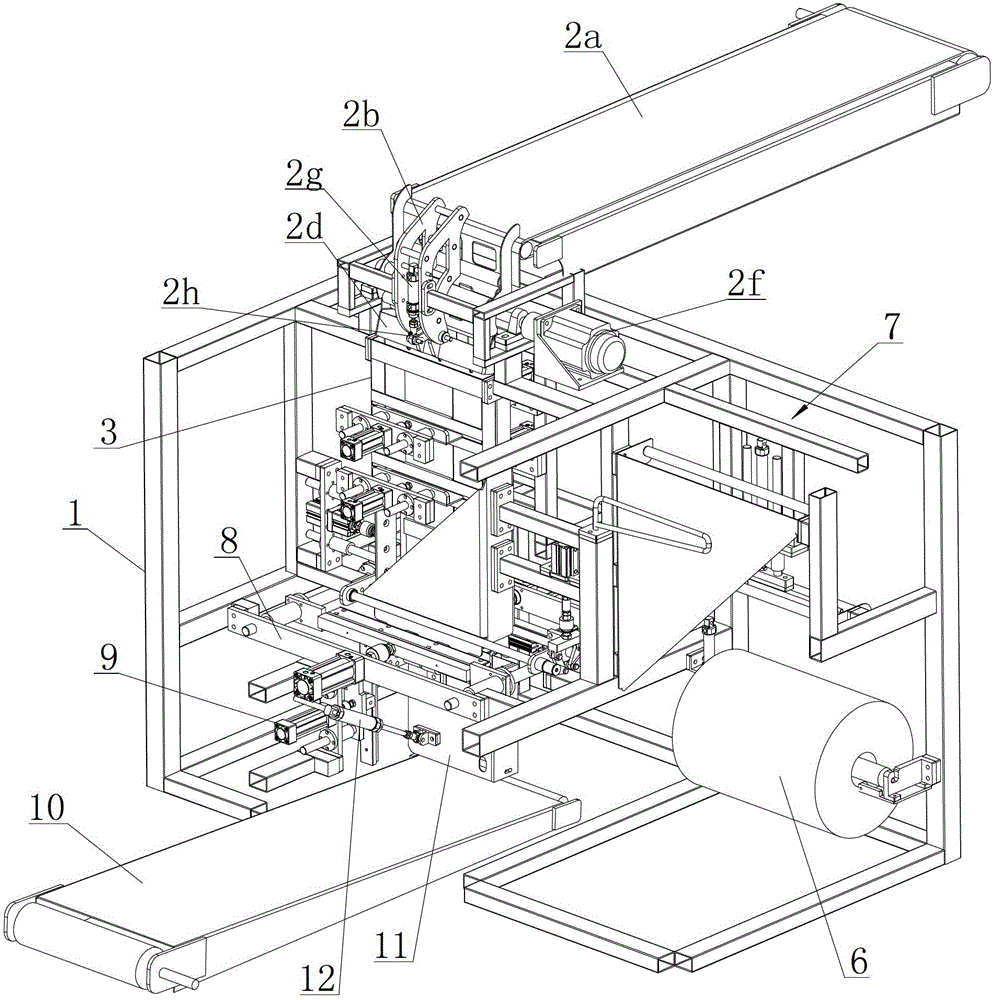

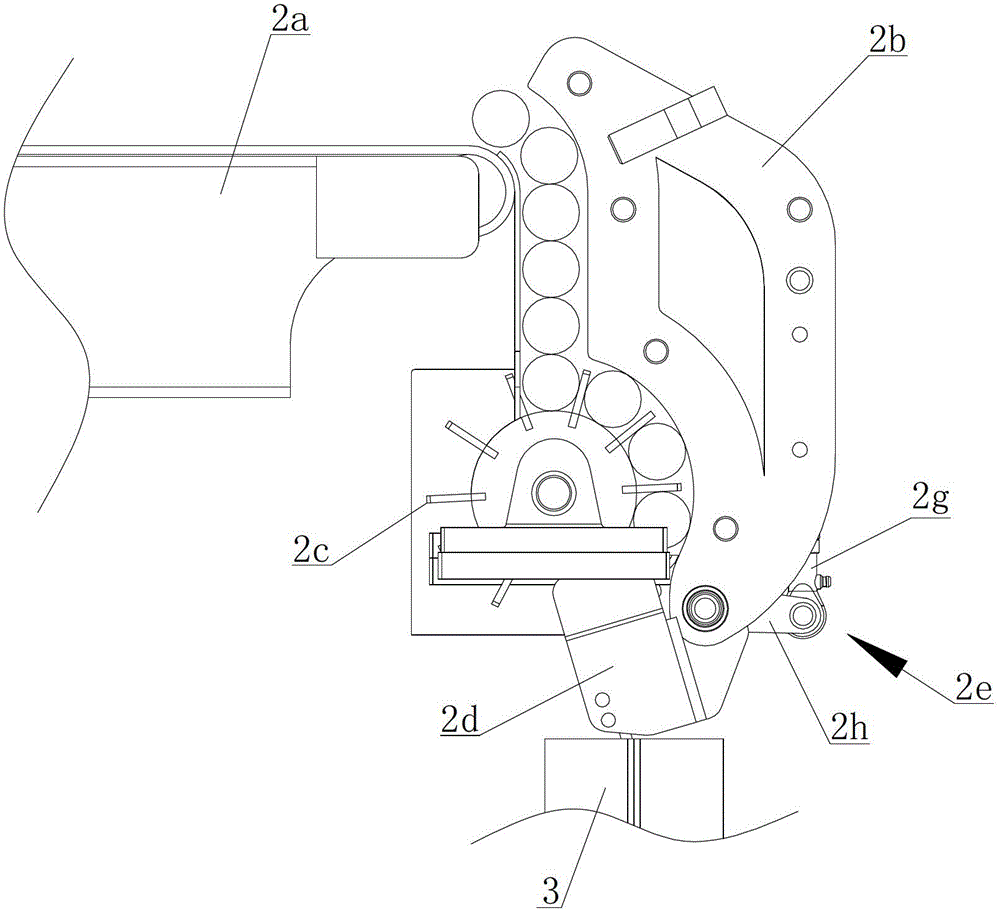

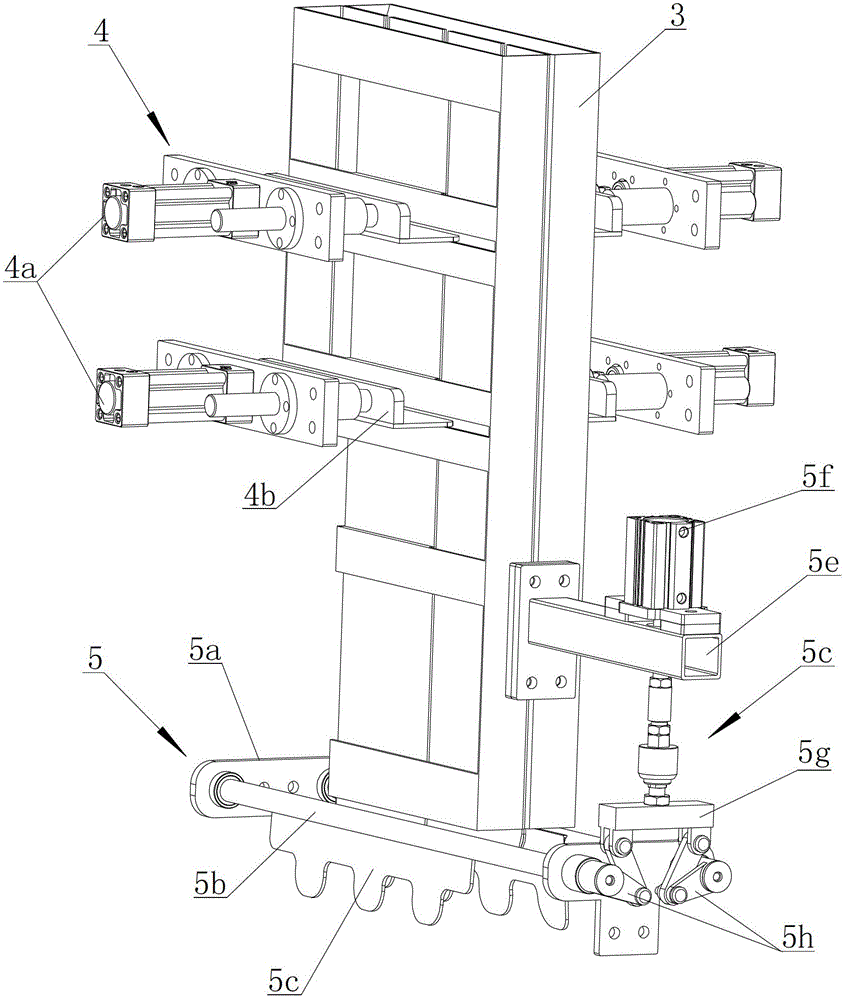

[0028] refer to Figure 1 to Figure 8As shown, a vertical packaging machine for emulsion explosives of the present invention includes a frame 1, a feeding mechanism 2 is provided on the top of the frame 1, and a feeding mechanism 2 is arranged on the frame 1 on the lower side of the feeding mechanism 2 along the vertical direction. There are at least two rows of code bins 3, and the size of each row of code bins 3 is adapted to the size of the emulsion explosive to be stacked. In this embodiment, there are two code bins 3, two code bins 3 are arranged side by side, separated by partitions in the middle; on the side walls of the drug bins 3 of each code, a number of stopper mechanisms 4 are arranged at intervals along the vertical direction, and the stopper mechanisms 4 are connected to the external main control unit circuit. There are two stopper mechanisms 4 on the side walls of the medicine bins 3 in each yard. The stopper mechanisms 4 are to prevent the medicine rolls from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com