Combined device for small-angle and wide-angle X-ray scattering and experiment test method of combined device

An X-ray and wide-angle technology, which is applied in the field of small-angle and wide-angle X-ray scattering combined devices and their experimental tests, can solve problems such as research that is difficult to characterize, limitations, and limited space, and achieves high light flux and brightness. The spot size is continuously adjustable, easy to install and debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

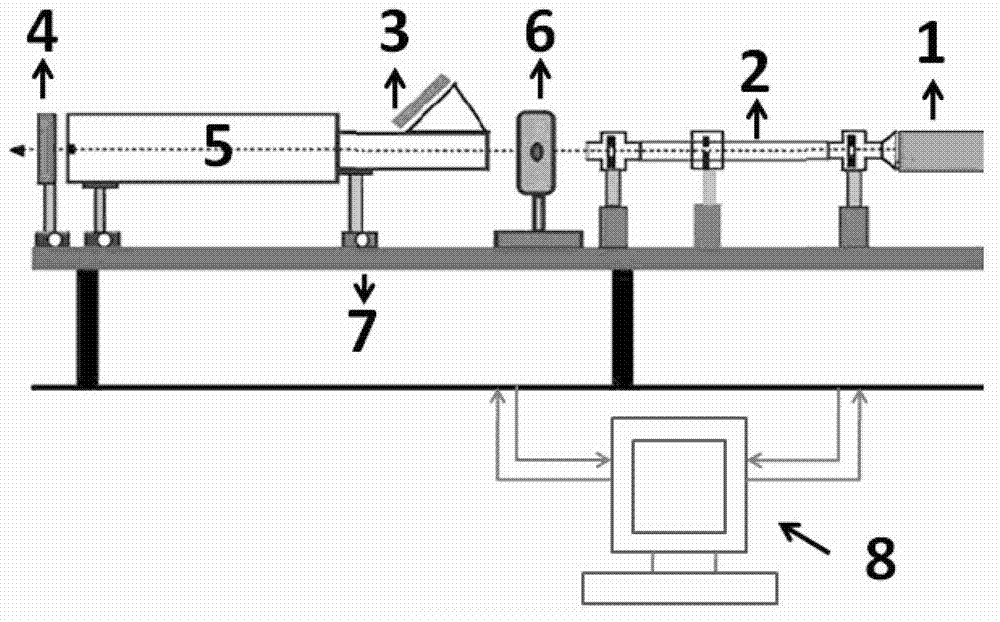

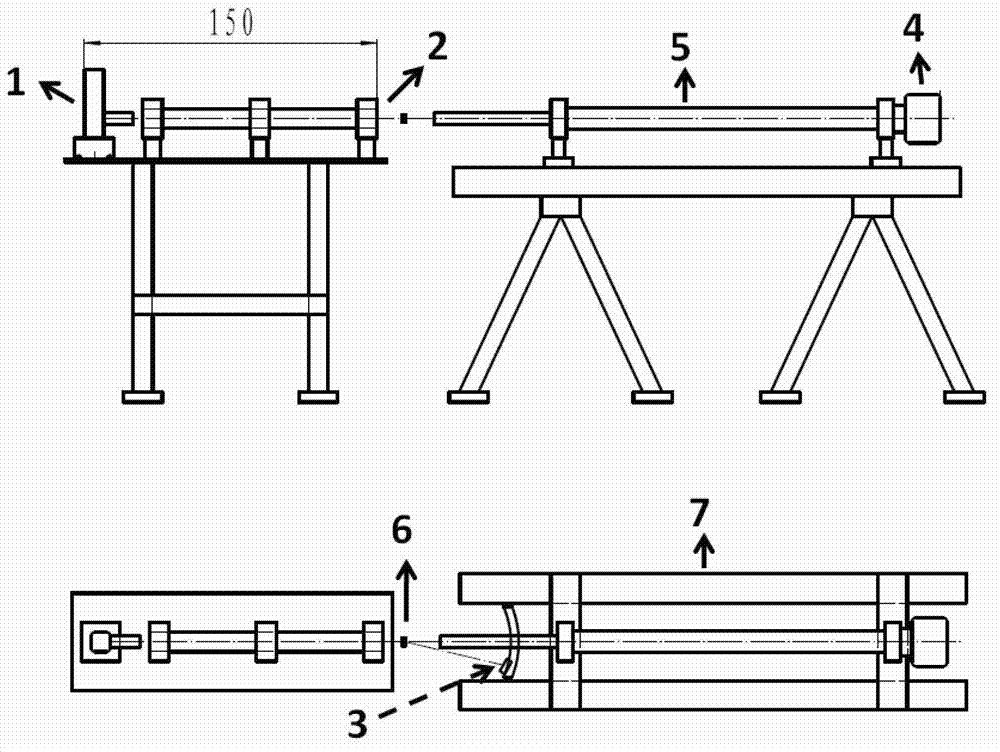

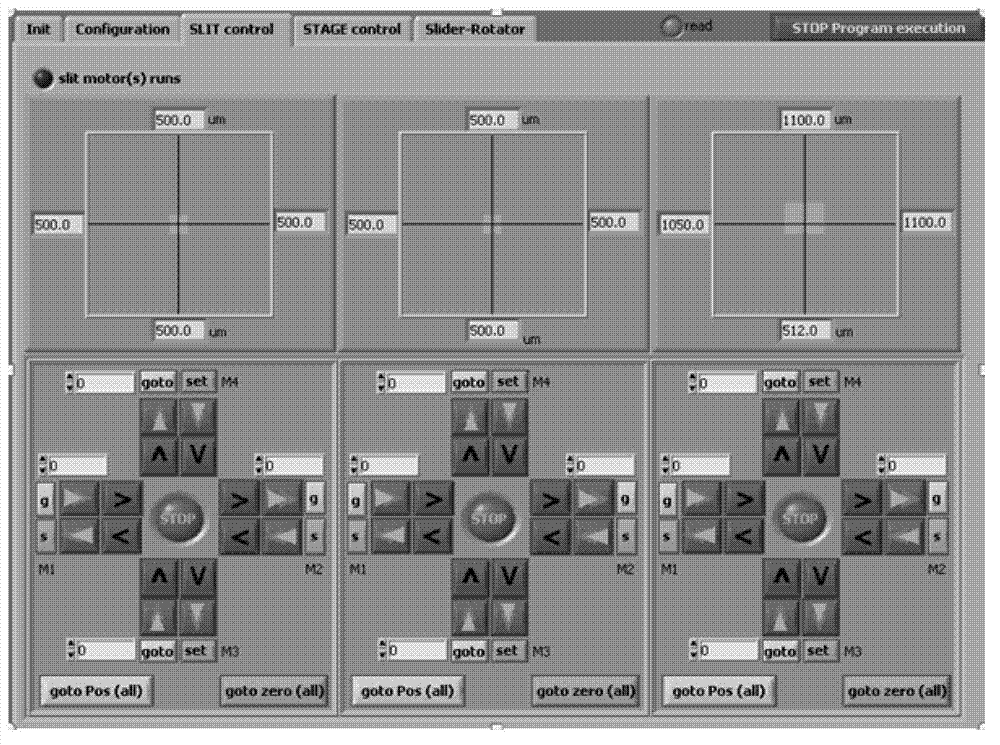

Method used

Image

Examples

experiment example 1

[0055] A 1D linear detector detects a wide range of angles for testing.

[0056] experiment procedure:

[0057] Firstly, the micro-focus X-ray light source is raised to full power (45KV, 650μA), and the three four-knife slit collimation optical paths are evacuated to the normal state (about 3×10 -1 mbar). Place the one-dimensional linear detector at a suitable position about 90mm away from the sample. Turn on the mixed gas of argon / methane (90 / 10), adjust the pressure to about 7.5 bar, the gas flow rate is about 0.17-0.45 I Ar / h, and flush the detector for 30 minutes. Adjust the bias voltage of the one-dimensional linear detector to 3.3KV, and then slowly increase the bias voltage to about 3.7KV, so that the energy spectrum peak position is at the channel number of 650-700. Turn on the light source shutter and the one-dimensional linear detector acquisition software to collect the X-ray one-dimensional scattering diagram of isotactic polypropylene.

[0058] Experimental re...

experiment example 2

[0061] Largest-scale testing of small-angle measurements in two-dimensional multi-filament gas detectors.

[0062] experiment procedure:

[0063] Adopt 1600mm vacuum pipe, 4×4.2mm 2 The straight-through light blocker combination is installed to adjust the light path. Three four-blade slit collimation optical paths and vacuum pipes are evacuated to normal state (about 3×10 -1 mbar), turn up the microfocus X-ray source to full power (45KV, 650μA). Adjust the slit collimation light path, define a certain spot size, and block stray light. Bovine tendon collagen was placed on the sample stage as a standard sample for detection.

[0064] Experimental results:

[0065] Figure 6 It is the two-dimensional small-angle scattering diagram of bovine tendon collagen under this test condition and the one-dimensional scattering curve obtained by integrating the two-dimensional small-angle scattering diagram. Experimental results show that the largest scale of the small-angle test is l...

experiment example 3

[0067] In situ study of the structural evolution of the nanolayered sample S6 during the swelling process.

[0068] experiment procedure:

[0069] Adopt 800mm vacuum pipe, 6×6mm 2 The straight-through light blocker combination is installed to adjust the light path. Three four-blade slit collimation optical paths and vacuum pipes are evacuated to normal state (about 3×10 -1 mbar), turn up the microfocus X-ray source to full power (45KV, 650μA). Adjust the bias voltage of the one-dimensional linear detector to 3.3KV, and then slowly increase the bias voltage to about 3.7KV, so that the energy spectrum peak position is at the channel number of 650-700. Turn on the 2D multifilament gas detector power and bias. Place the S6 sample in the sample cell, and simultaneously turn on the one-dimensional linear detector and the two-dimensional multi-wire gas detector to collect wide-angle and small-angle signals. During the experiment, a micro-injector was used to gradually add water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com