High-power irradiation accelerator X-ray conversion target and high-power irradiation accelerator X-ray conversion device

An X-ray and accelerator technology, applied in the field of high-power irradiation accelerator X-ray conversion targets and conversion devices, can solve the problems of low electron beam penetration and difficulty in further expansion, avoid target deformation or early damage, and broaden applications field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

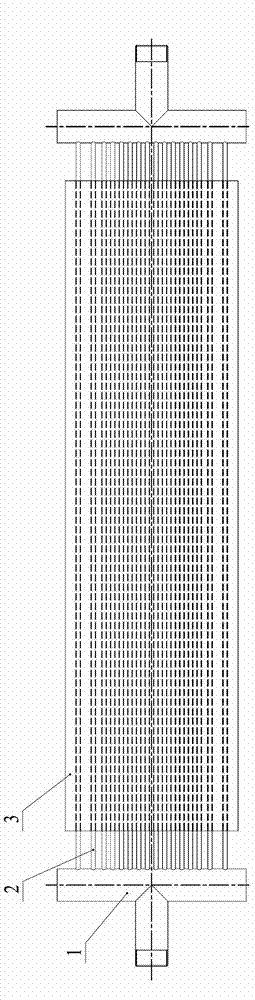

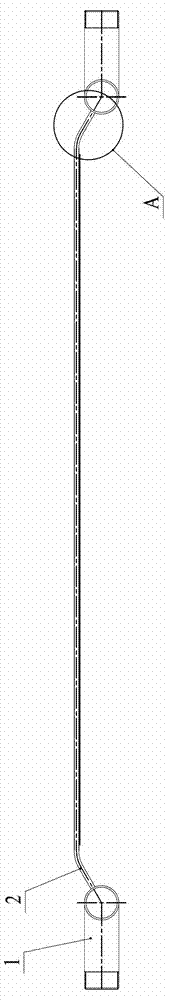

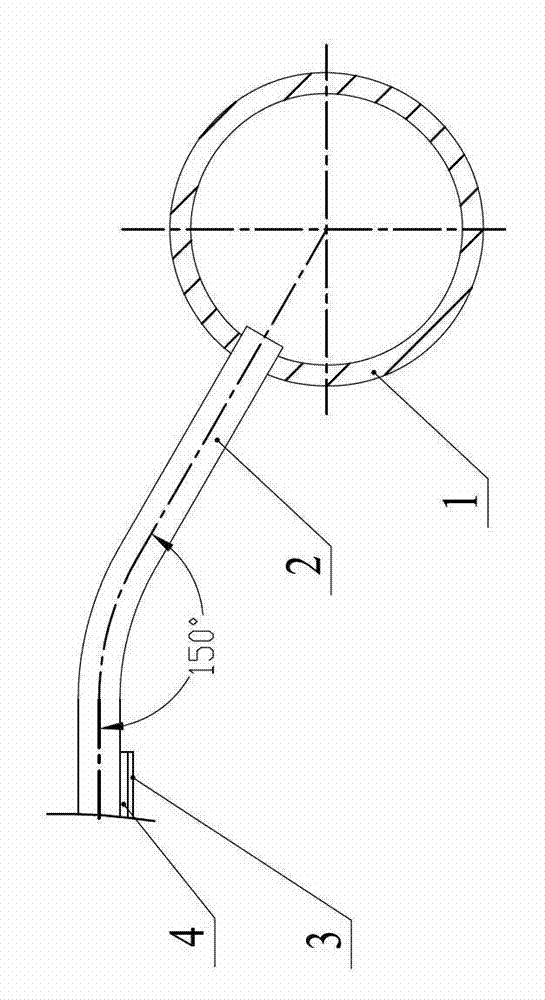

[0017] Such as Figure 1~Figure 3 As shown, the high-power irradiation accelerator X-ray conversion target in the embodiment mainly includes a target body and a target body cooling device. The target body is mainly composed of a tantalum plate 3 and a copper plate 4, and the front surface of the tantalum plate 3 is used for receiving The electron beam is converted into X-rays, and the rear surface of the tantalum plate 3 is welded to the front surface of the copper plate 4 as a whole; the target cooling device is mainly composed of two main cooling tubes 1 and a plurality of branch cooling tubes 2. The root and branch cooling pipes 2 are arranged in parallel and are welded on the rear surface of the copper plate 4. The two main cooling pipes 1 are respectively welded to the two ends of the multiple branch cooling pipes 2 and communicate with the branch cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com