Balancing device for multi-stage pump and surface additive manufacturing method

A balancing device and multi-stage pump technology, which is applied to the parts of the pumping device for elastic fluid, additive processing, pumps, etc., can solve the problems of shortened service life and large wear, and achieve improved wear resistance and uniform hardness , The method is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

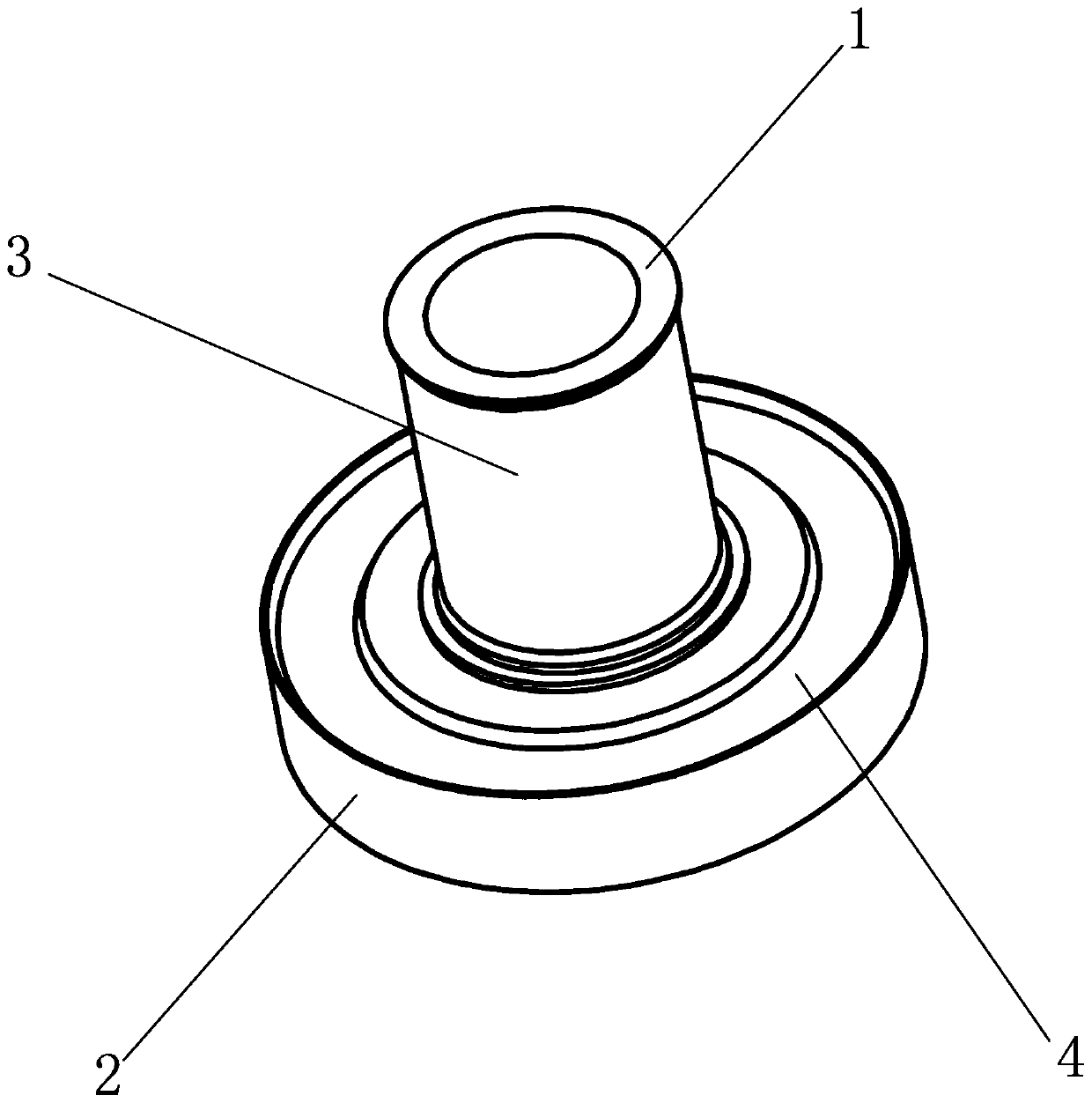

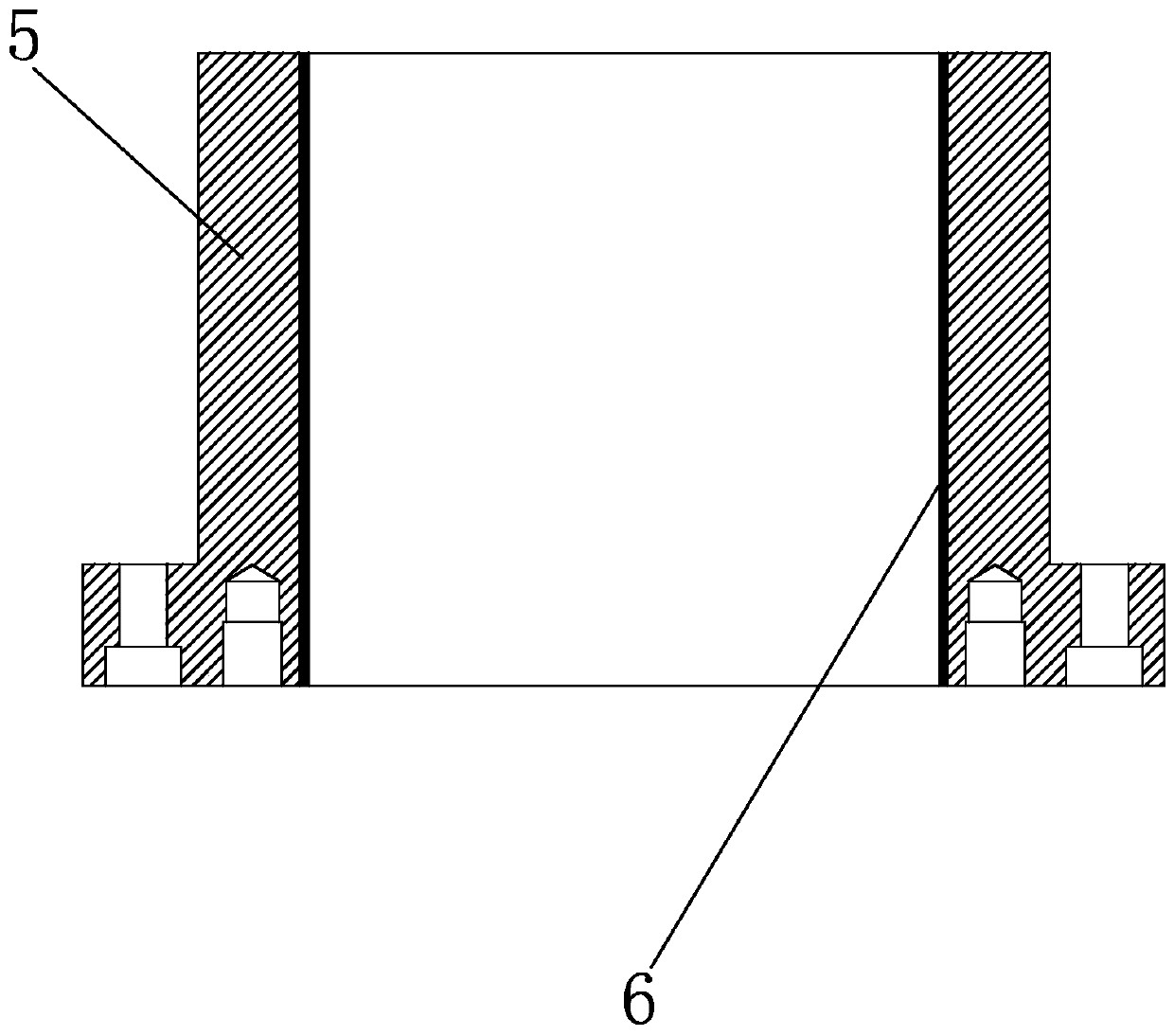

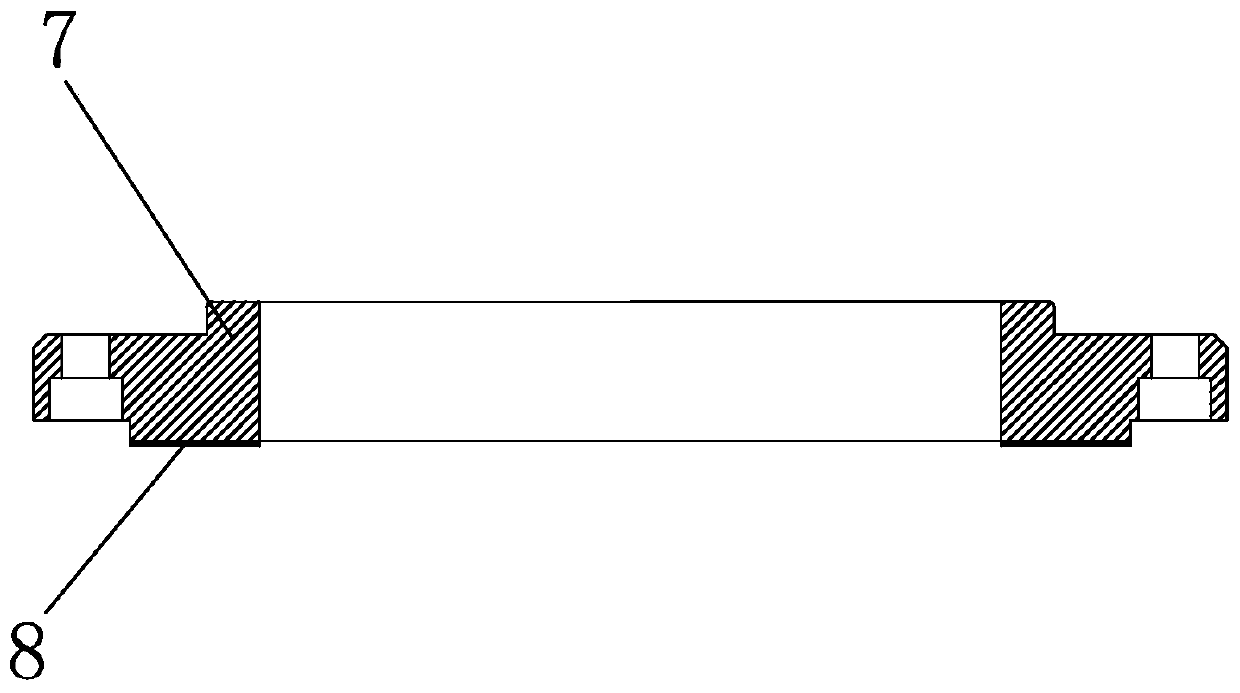

[0045] A surface additive manufacturing method of a balance device for a multi-stage pump. The laser additive cladding method is used to manufacture the first laser cladding layer, the second laser cladding layer, the third laser cladding layer and the fourth laser cladding layer. The cladding adopts the balance sleeve 5, the balance plate and the balance plate 9 as specific components, including the following steps:

[0046] Step 1. Laser cladding the first laser cladding layer on the matching A side 3 of the balance device. The laser cladding power is 2800W. During the laser cladding process, the circumferential rotation speed is 4.5rmp / min, and the cladding material is Ni40 cladding Material, the thickness of the first laser cladding layer is (1.6±0.1) mm.

[0047] Step 2. Laser cladding the second laser cladding layer on the matching B side 6 of the balance device. The laser cladding power is 2500W. During the laser cladding process, the circumferential rotation speed is 5rmp / m...

Embodiment 2

[0052] A method for surface additive manufacturing of a balance device for a multi-stage pump. The laser additive cladding method is used to manufacture the first laser cladding layer, the second laser cladding layer, the third laser cladding layer and the fourth laser cladding layer. The cladding adopts the balance sleeve 5, the balance plate and the balance ring 7 as specific components, including the following steps:

[0053] Step 1. Laser cladding the first laser cladding layer on the matching A side 3 of the balance device. The laser cladding power is 2800W. During the laser cladding process, the circumferential rotation speed is 4.5rmp / min, and the cladding material is Ni40 cladding Material, the thickness of the first laser cladding layer is (2.4±0.1) mm.

[0054] Step 2. Laser cladding the second laser cladding layer on the matching B side 6 of the balance device. The laser cladding power is 2500W. During the laser cladding process, the circumferential rotation speed is 5rm...

Embodiment 3

[0059] A method for surface additive manufacturing of a balance device for a multi-stage pump. The laser additive cladding method is used to manufacture the first laser cladding layer, the second laser cladding layer, the third laser cladding layer and the fourth laser cladding layer. The cladding adopts the balance drum, balance plate and balance plate 9 as specific components, including the following steps:

[0060] Step 1. Laser cladding the first laser cladding layer on the matching A side 3 of the balance device. The laser cladding power is 2800W. During the laser cladding process, the circumferential rotation speed is 4.5rmp / min, and the cladding material is Ni40 cladding Material, the thickness of the first laser cladding layer is (1.8±0.1) mm.

[0061] Step 2. Laser cladding the second laser cladding layer on the matching B side 6 of the balance device. The laser cladding power is 2500W. During the laser cladding process, the circumferential rotation speed is 5rmp / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com