PDP (Plasma Display Panel) light filtering membrane and method for preparing same

A technology of filter film and base film, which is applied in the direction of filter, optics, optical components, etc., can solve the problems of low rainbow pattern, no mention, high difficulty of control, etc., and achieve the effect of low rainbow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

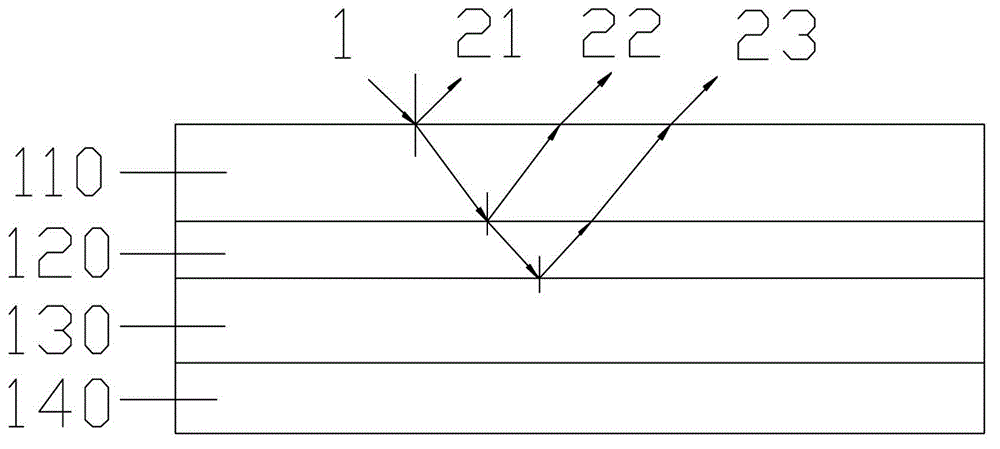

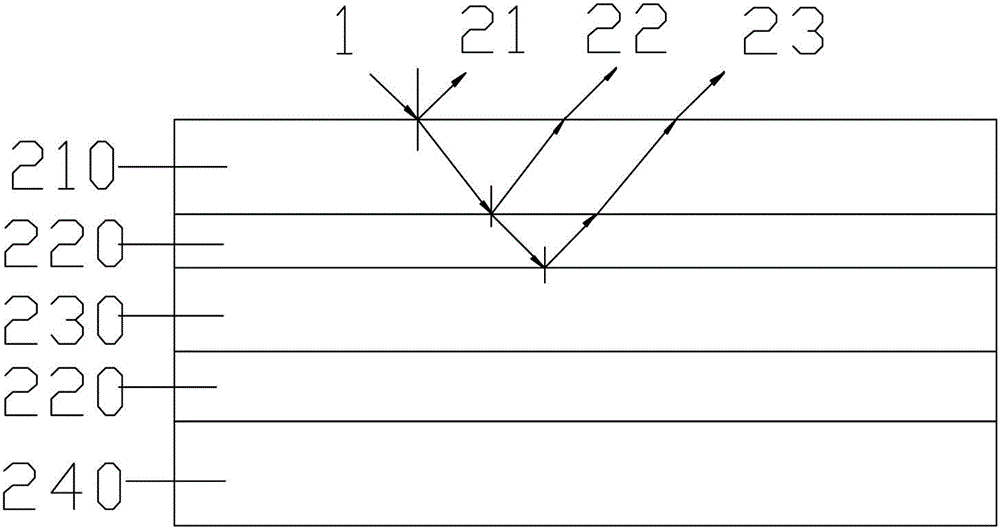

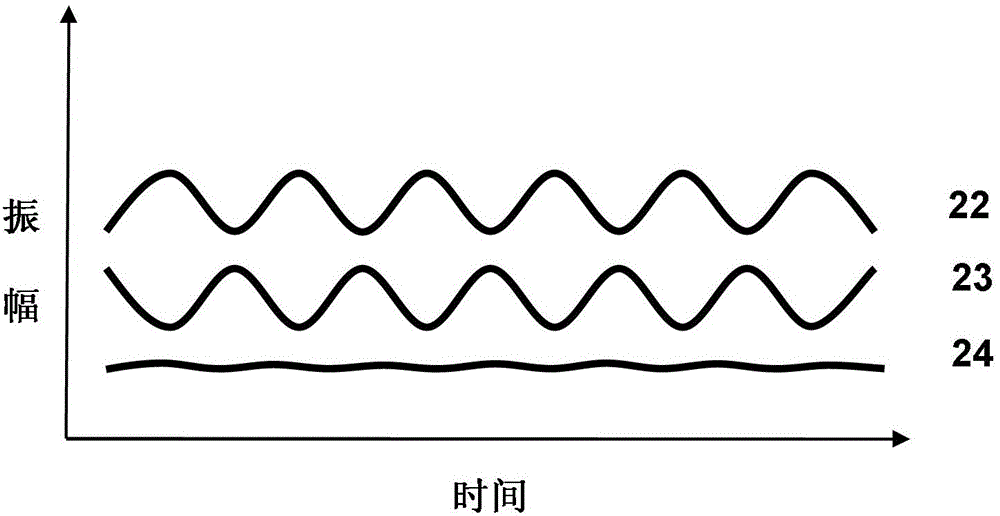

[0054] A commercially available optical PET base film A with a double-sided easy-adhesive pre-coat was used, the refractive index of the double-sided easy-adhesive pre-coat was 1.57, and the refractive index of the PET base film was 1.63. According to the formula (n 2 ) 2 =n 1 ×n 3 , the optimal refractive index of the required coating with low iridescence, antistatic, hardening and anti-reflection functions is 1.51.

[0055] By adjusting the ratio of the coating materials, the refractive index of the coating is 1.51, and the ratio of the coating by mass fraction is as follows:

[0056] Hardening particle silicon dioxide 10%, crosslinking agent butyl acrylate 30%, photosensitizer phenyl 4-methylbenzyl 3%, antistatic particle indium oxide 15%, solvent ether 30%, xylene 12% .

[0057] Coating thickness is controlled at 5um±10%.

[0058] First fully dissolve silicon dioxide and tin-doped indium oxide in ether; then fully mix butyl acrylate and phenyl 4-methylbenzyl in an ai...

Embodiment 2

[0061] A commercially available optical PET base film B with a double-sided easy-adhesive pre-coat was used, the refractive index of the double-sided easy-adhesive pre-coat was 1.55, and the refractive index of PET was 1.61. According to theoretical calculation, the optimal refractive index of the required coating with low iridescence, antistatic, hardening and anti-reflection functions is 1.49.

[0062] By adjusting the material ratio of the coating material, the refractive index of the coating is 1.49, and the coating ratio is as follows:

[0063] Hardening particle magnesium fluoride 17%; crosslinking agent -1,4-butylene glycol diacrylate 22%; photosensitizer gold ammonium thiocyanate 5%; antistatic particle indium oxide 18%; solvent ethyl acetate 28%, butanone 10%.

[0064]Coating thickness is controlled at 5um±10%.

[0065] First fully dissolve silicon dioxide and indium oxide in ethyl acetate; then fully mix 1,4-butanediol diacrylate and gold ammonium thiocyanate in an...

Embodiment 3

[0068] A commercially available optical PET base film C with a double-sided easy-adhesive pre-coat was used, the refractive index of the double-sided easy-adhesive pre-coat was 1.60, and the refractive index of PET was 1.66. According to theoretical calculation, the optimal refractive index of the required coating with low iridescence, antistatic, hardening and anti-reflection functions is 1.54.

[0069] By adjusting the material ratio of the coating material, the refractive index of the coating is 1.54, and the coating ratio is as follows:

[0070] Hardening particles magnesium fluoride 10%, silicon dioxide 5%; crosslinking agent acrylic acid 25%; photosensitizer 2-chlorothioxanthone 5%; antistatic particles zinc oxide 10%, indium oxide 8%; solvent ethyl acetate was 37%.

[0071] The preparation process is the same as in Example 2.

[0072] It has been verified by a large number of experiments that when the PDP filter film is applied to a PDP display, there is no obvious ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com