Surface hardened graphite mold and method of surface hardening

A graphite mold, surface deposition technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of easy wear and depression, high density, no more than several thousand times, etc., to achieve good resistance. The effect of friction and high temperature oxidation resistance, improving hardness and wear resistance, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

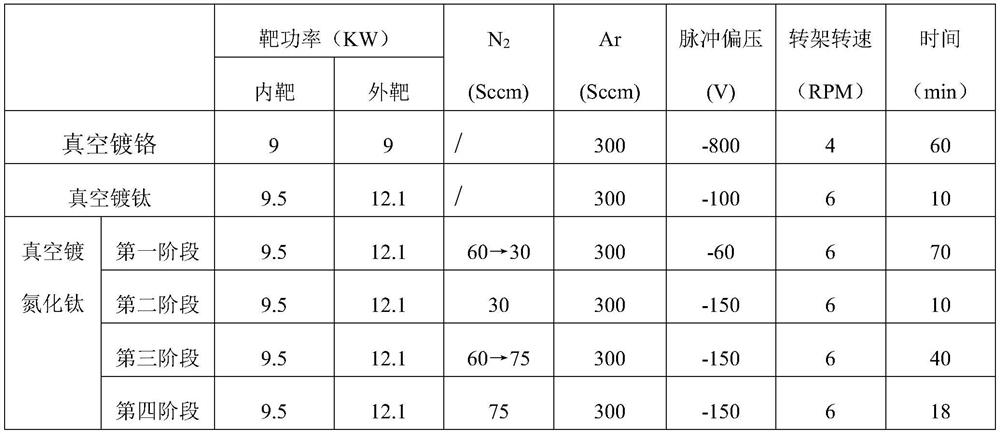

[0041] The present embodiment is a method for hardening the surface of a graphite mold, and the steps are as follows:

[0042] (1) Surface pretreatment

[0043] The graphite mold is fixed on the turn frame placed in the vacuum chamber of the PVD furnace, and the surface of the graphite mold is cleaned with plasma to obtain the cleaned graphite mold.

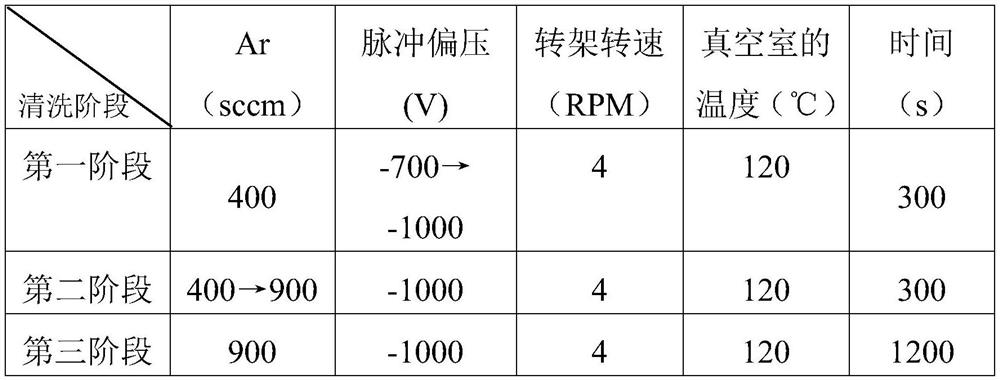

[0044] According to the different process parameters (see Table 1), the cleaning of the graphite mold is divided into the following three stages, and in these three stages, the temperature of the vacuum chamber of the PVD furnace needs to be kept at 120 °C, and the rotation speed of the turret should be kept at 120°C. 4RPM:

[0045] The first stage: adjust the vacuum degree of the vacuum chamber of the PVD furnace to 3.0×10 -3 , and then pour argon with a flow rate of 400sccm into the vacuum chamber;

[0046] The pulse bias applied to the graphite mold increased from -700V to -1000V. During the process of applying the pulse bi...

Embodiment 2

[0074] (1) Pretreatment of the surface:

[0075] The graphite mold is fixed on the turn frame placed in the vacuum chamber of the PVD furnace, and the surface of the graphite mold is cleaned with plasma to obtain the cleaned graphite mold.

[0076] According to the different process parameters (see Table 3), the cleaning of the graphite mold is divided into the following three stages, and in these three stages, the temperature of the vacuum chamber of the PVD furnace needs to be kept at 120 ℃, and the rotation speed of the turret should be kept at 120°C. 4RPM:

[0077] The first stage: adjust the vacuum degree of the vacuum chamber of the PVD furnace to 2.8×10 -3 , and then pour argon with a flow rate of 400sccm into the vacuum chamber;

[0078] The pulse bias applied to the graphite mold increased from -700V to -1000V. During the process of applying the pulse bias to the graphite mold, a large number of argon ions were generated on the surface of the graphite mold. The argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com