High-pressure fuel pump

A high-pressure pump and fuel technology, which is used in fuel injection pumps, fuel injection devices, liquid fuel engines, etc., to simplify the deburring method, reduce costs, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

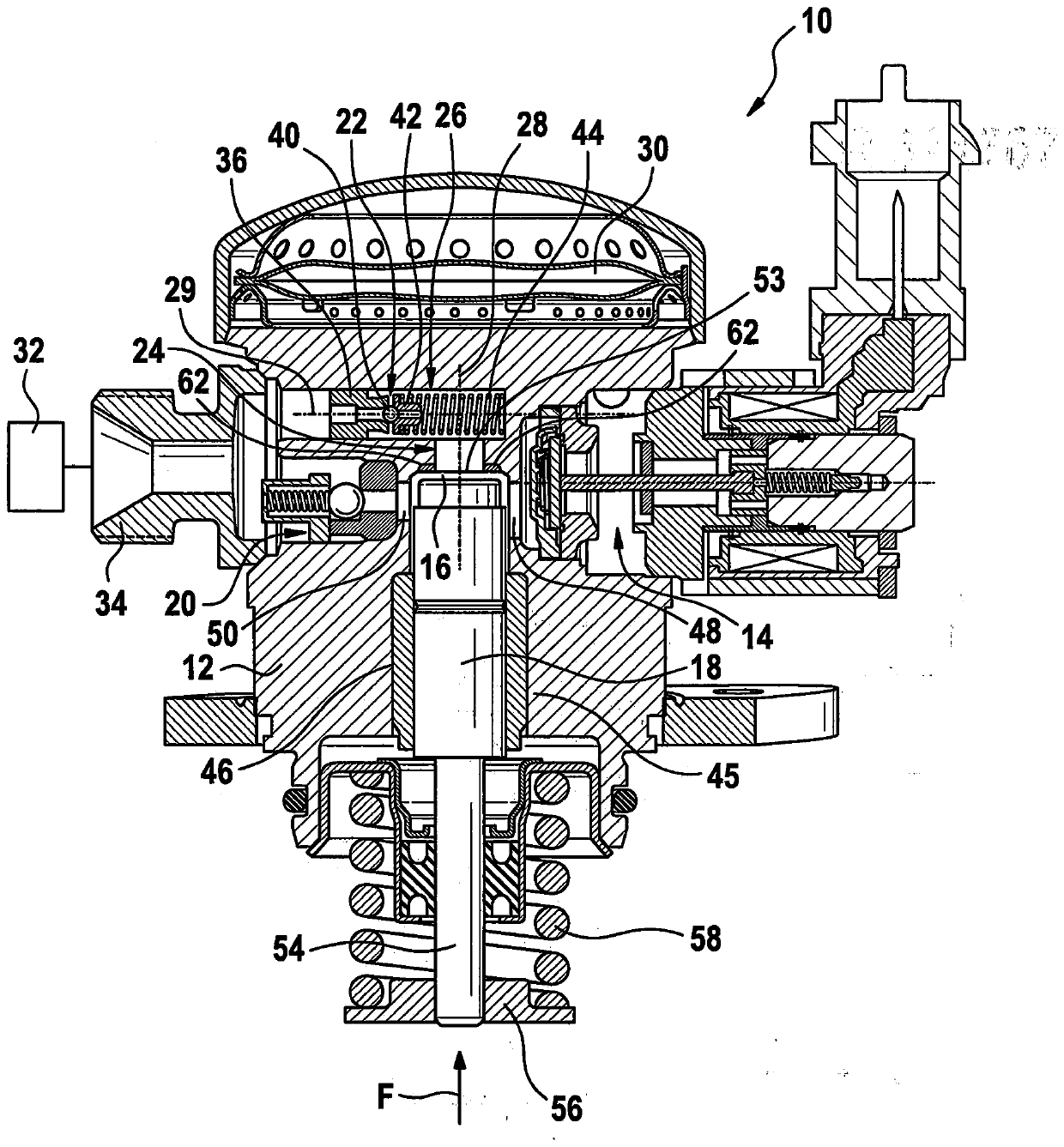

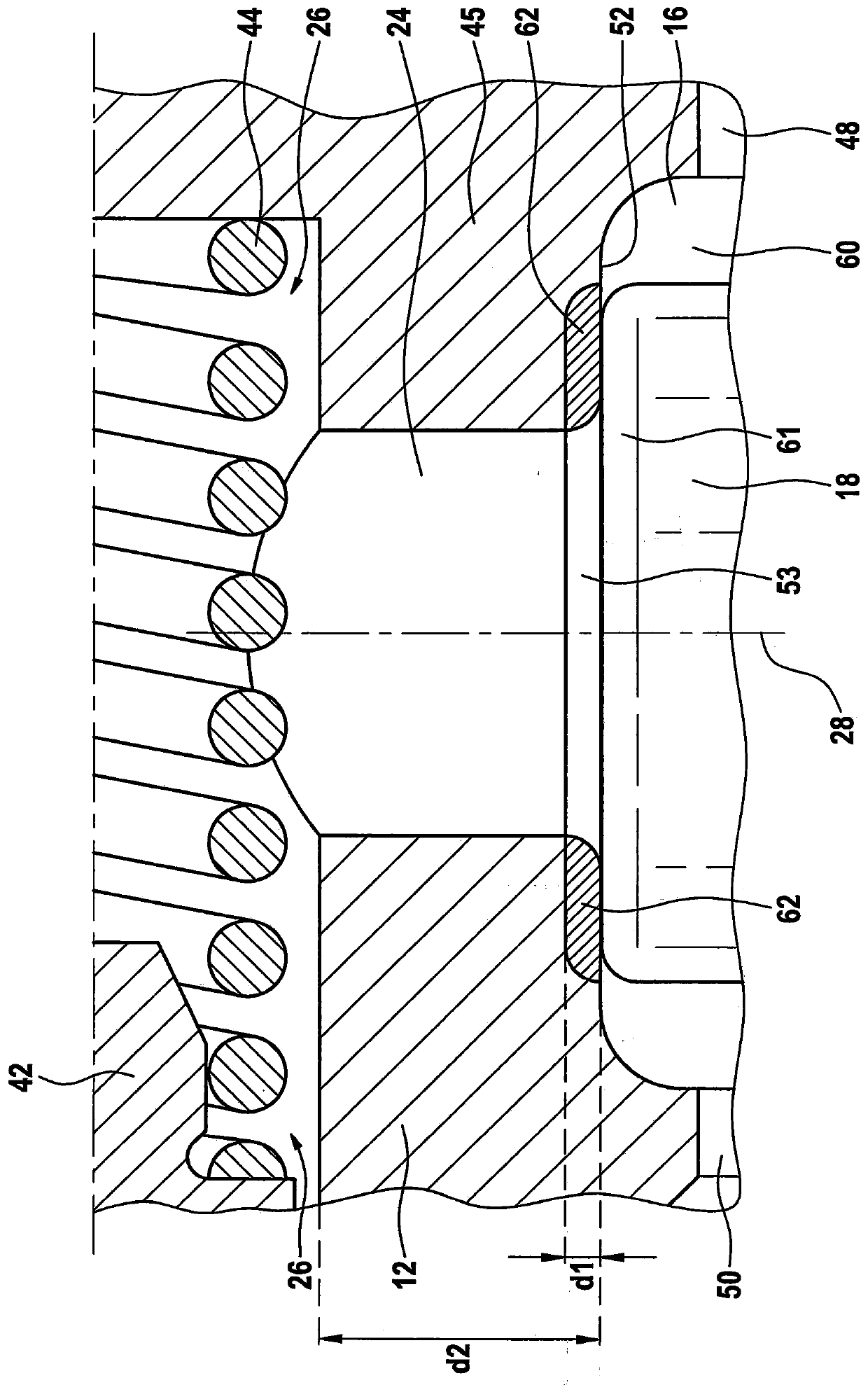

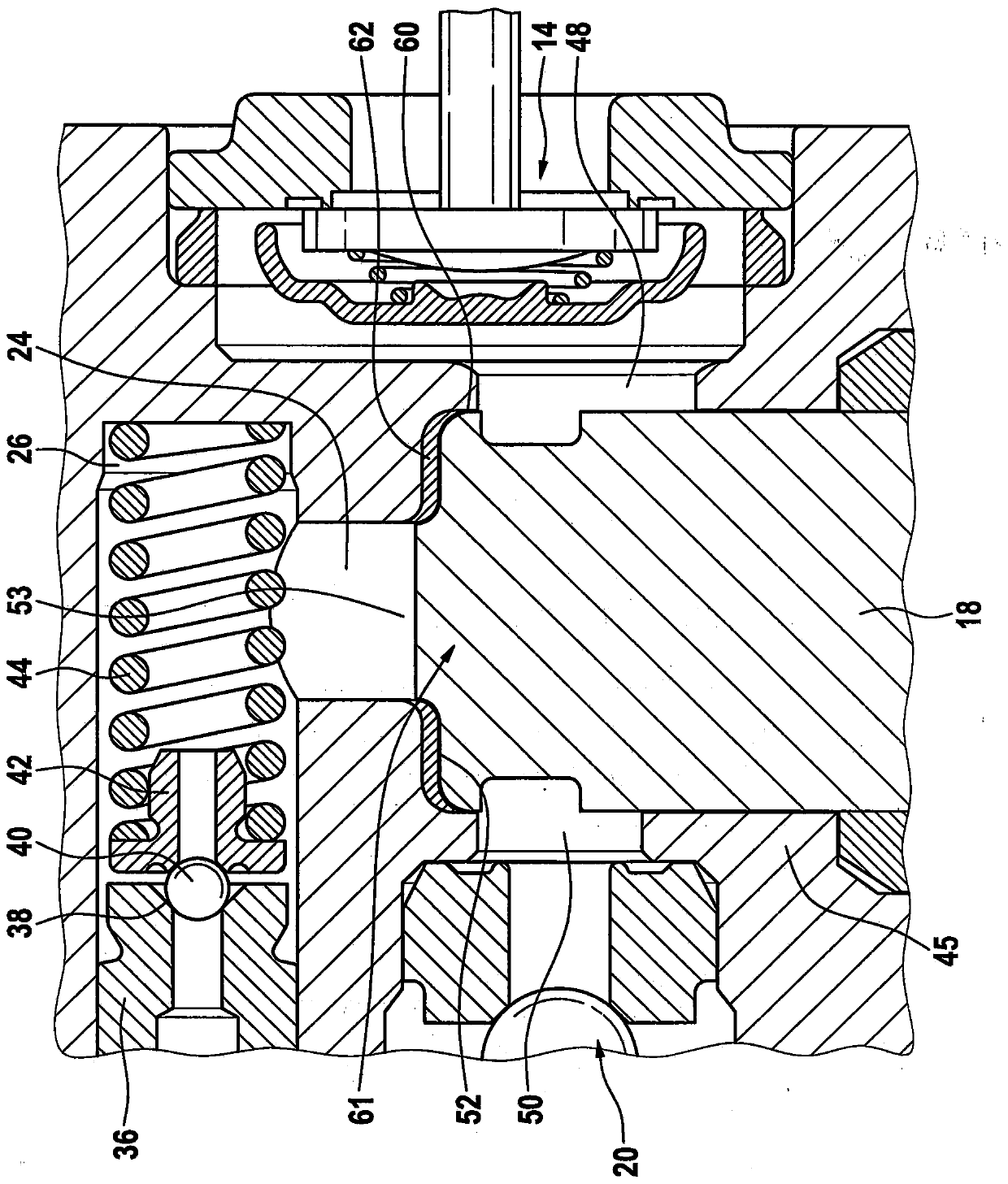

[0023] exist figure 1 10 , the high-pressure fuel pump for an internal combustion engine, not shown in detail, is generally designated 10 . The high-pressure fuel pump 10 has an overall substantially cylindrical pump housing 12 in or on which the main components of the high-pressure fuel pump 10 are arranged. The high-pressure fuel pump 10 has an inlet / flow control valve 14 , a delivery piston 18 arranged in a delivery chamber 16 , an outlet valve 20 and a pressure limiting valve 22 .

[0024] In the housing 12 there is a first channel 24 which extends coaxially to the delivery chamber 16 and the delivery piston 18 and leads from the delivery chamber 16 to a second channel 26 in the form of an overall substantially cylindrical groove, The groove is arranged at an angle of 90° to the first channel 24 and the pressure limiting valve 22 is received in the groove. The longitudinal axis of the pump housing 12 is at figure 1 The center generally bears the reference number 28 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com