Method for manufacturing float sheet glass and apparatus for manufacturing float sheet glass

A technology of float flat glass and manufacturing method, applied in glass production and other directions, can solve problems such as damage and deformation of bottom shell, and achieve the effect of suppressing bubbles and reducing bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

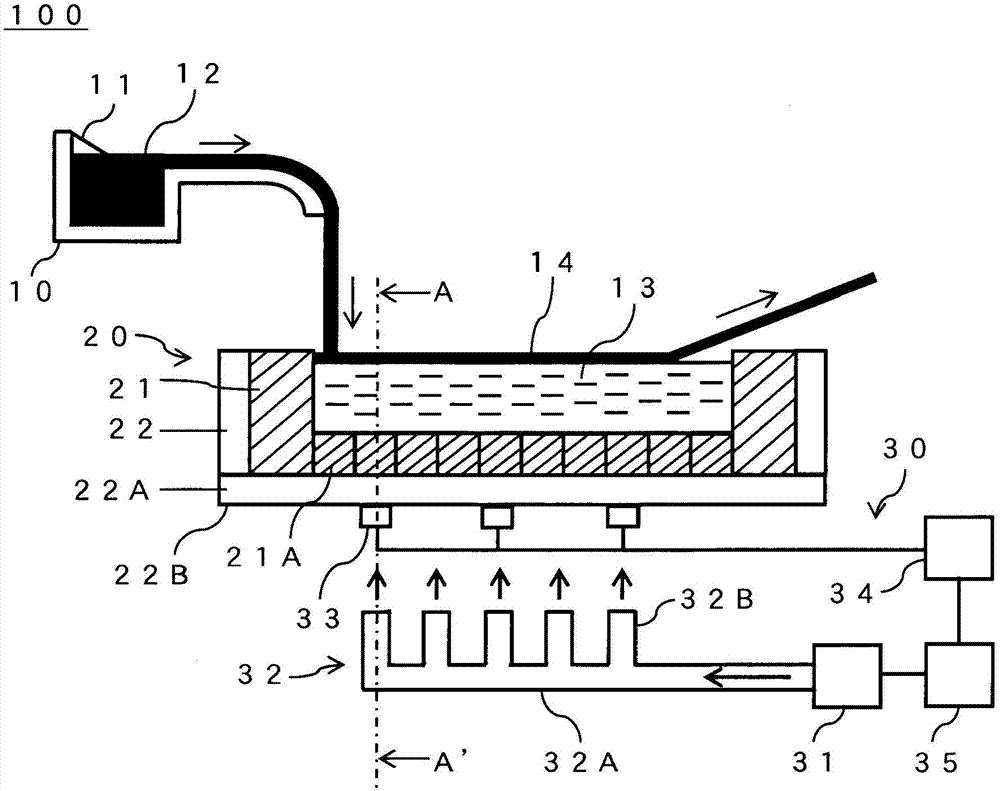

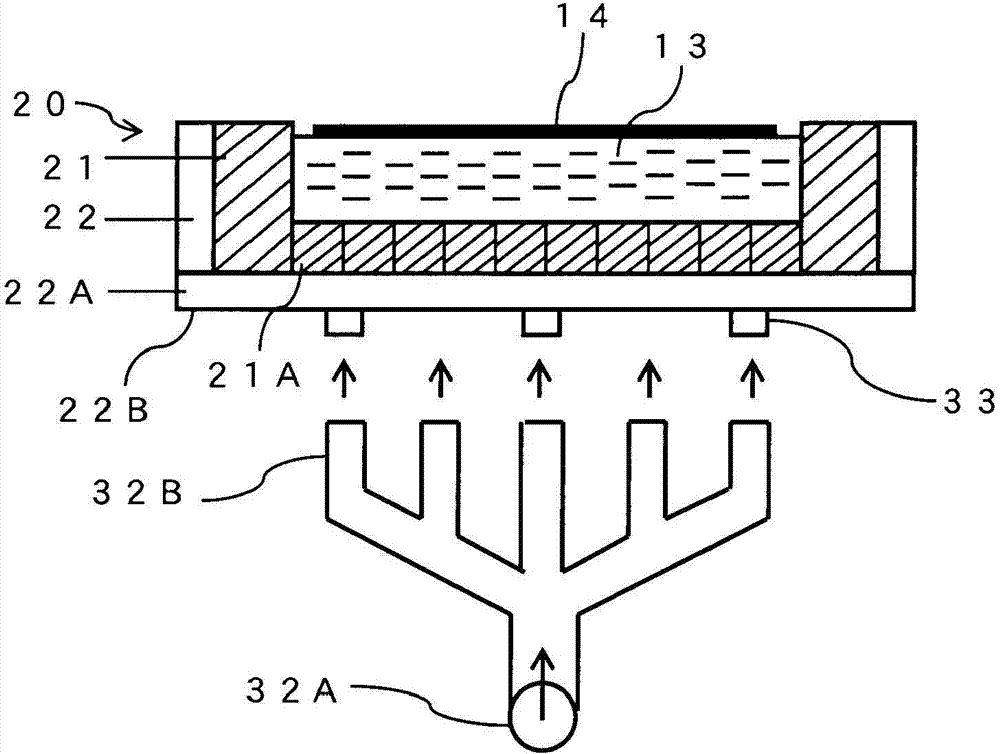

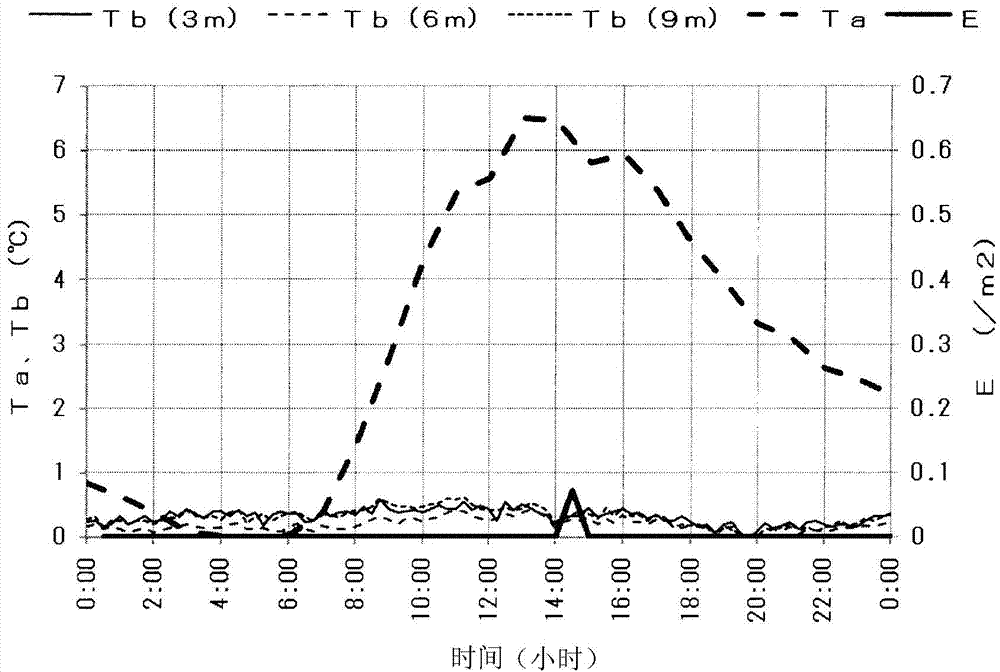

[0070] In Example 1, with figure 1 and figure 2 The illustrated method of manufacturing float-formed sheet glass produces sheet glass.

[0071] First, the raw material of alkali-free glass was thrown into a melting tank, and molten glass was manufactured.

[0072]Next, molten tin was accommodated in a bath provided with refractory bricks and an iron casing covering the refractory bricks. After containing the molten tin, it is cooled using a fluid supply device provided below the bottom shell so that the temperature of the outer surface of the bottom shell covering the bottom bricks forming the hearth of the bath is below the melting point of tin.

[0073] Then, the above-mentioned molten glass is continuously supplied onto the surface of the molten tin, and the molten glass is made to flow from upstream to downstream of the bath along the surface of the molten metal. During the flow of the molten glass, the fluid supply device blows air toward the outer surface of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com