Preparation method and product of unsterilized vacuum packed roast chicken

A technology of vacuum packaging and roasting chicken, which is applied in the field of food processing, can solve the problems of short shelf life and achieve the effect of delicious taste, rich aroma and avoiding cooking smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

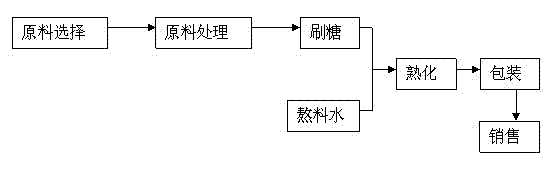

Method used

Image

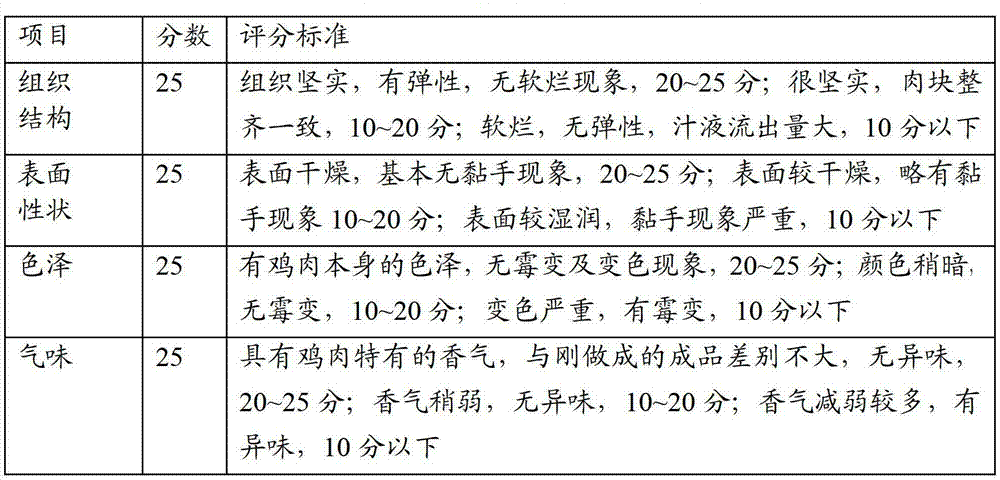

Examples

Embodiment Construction

[0024] (1) Selection of raw materials: Strictly select healthy three-yellow broiler chickens that meet the standards, whole eviscerated chickens after formal slaughter or suit chickens with heads, necks and claws removed (the weight of bare chickens is preferably 0.65kg).

[0025] (2) Raw material processing: remove the French bag at the end, the residual viscera fragments in the clean cavity, rinse inside and outside, remove all blood stains, pack and drain.

[0026] (3) Brush sugar: prepare sugar solution according to the ratio of water: caramel = 1:1, and then evenly coat the surface of chicken skin.

[0027] (4) Frying: use salad oil, the oil temperature is 170-180°C, fry for 1-2 minutes, and fry until orange-red.

[0028] (5) Ripening:

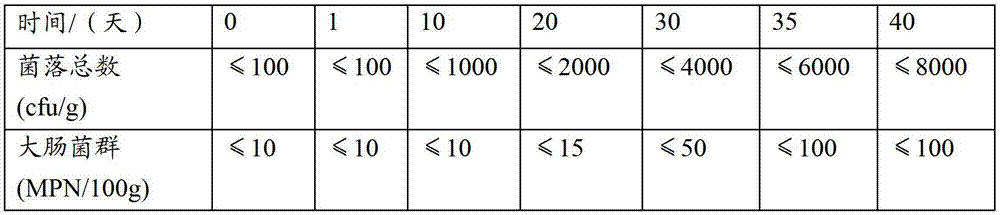

[0029] 1. Environmental microorganisms in the curing room ≤ 100cfu·m -3

[0030] 2. Add 2kg of ginger, 1.5kg of sugar, 1kg of monosodium glutamate, 5kg of refined salt, 0.2kg of kaempferen, 0.2kg of pepper, 0.2kg of star anise, 0.2kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com