Car transmission synchronizer gear ring fine blanking and deep drawing combined forming process and mold

A technology for synchronizer gear rings and automobile transmissions, which is applied to forming tools, manufacturing tools, and vehicle parts, etc. It can solve the problems of automobile synchronizer gear rings with many consumables, low material utilization rate, and low production efficiency, and reduce the number of processes , High utilization rate of materials, save the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation. Of course, the following examples should not be construed as limiting the present invention.

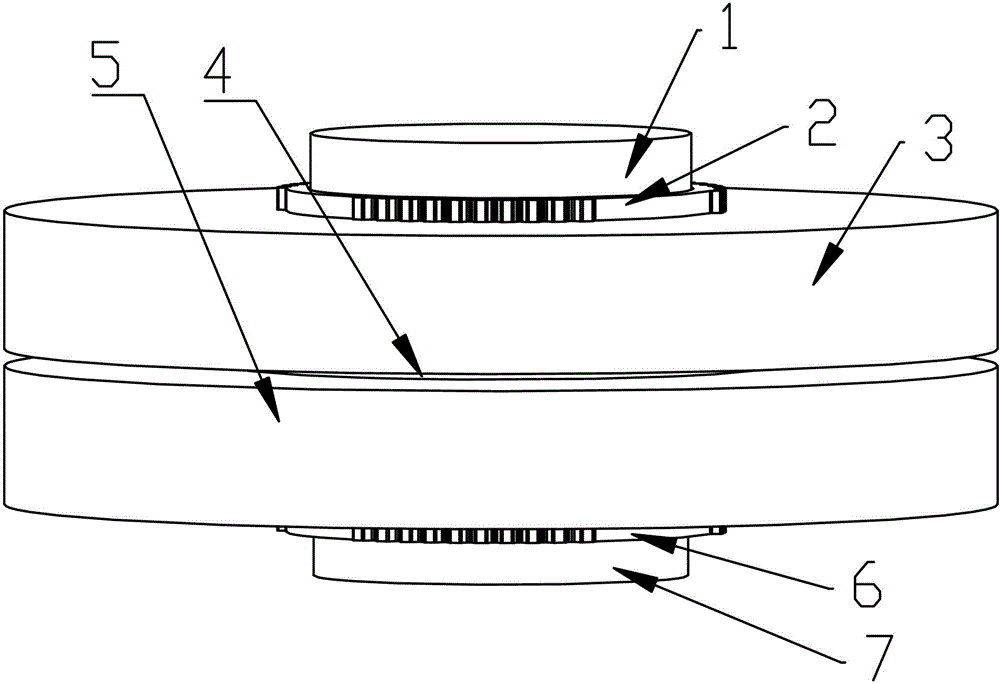

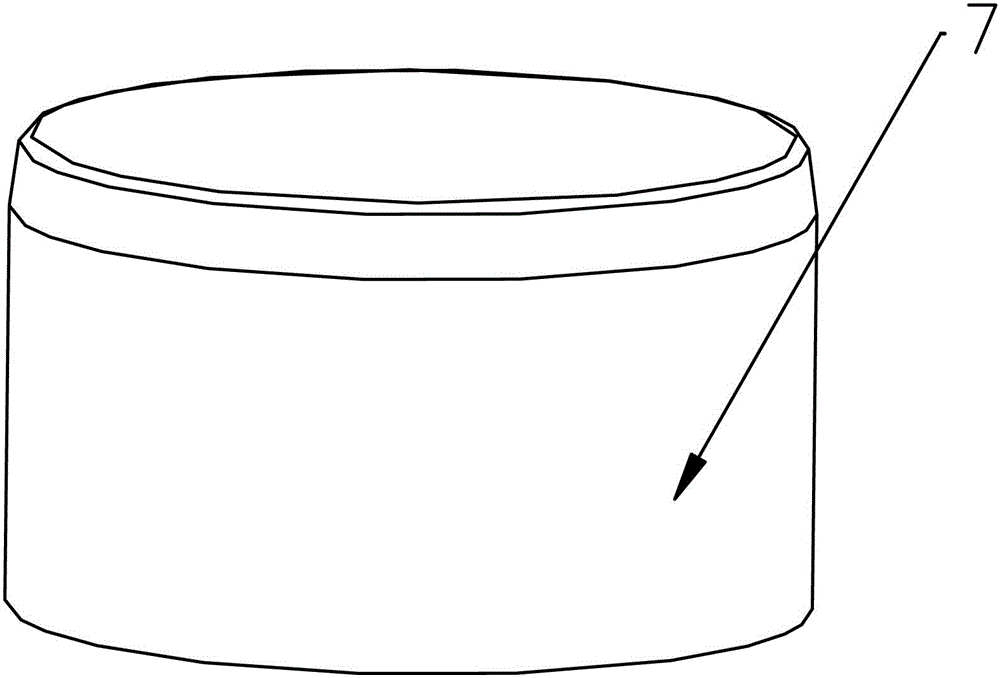

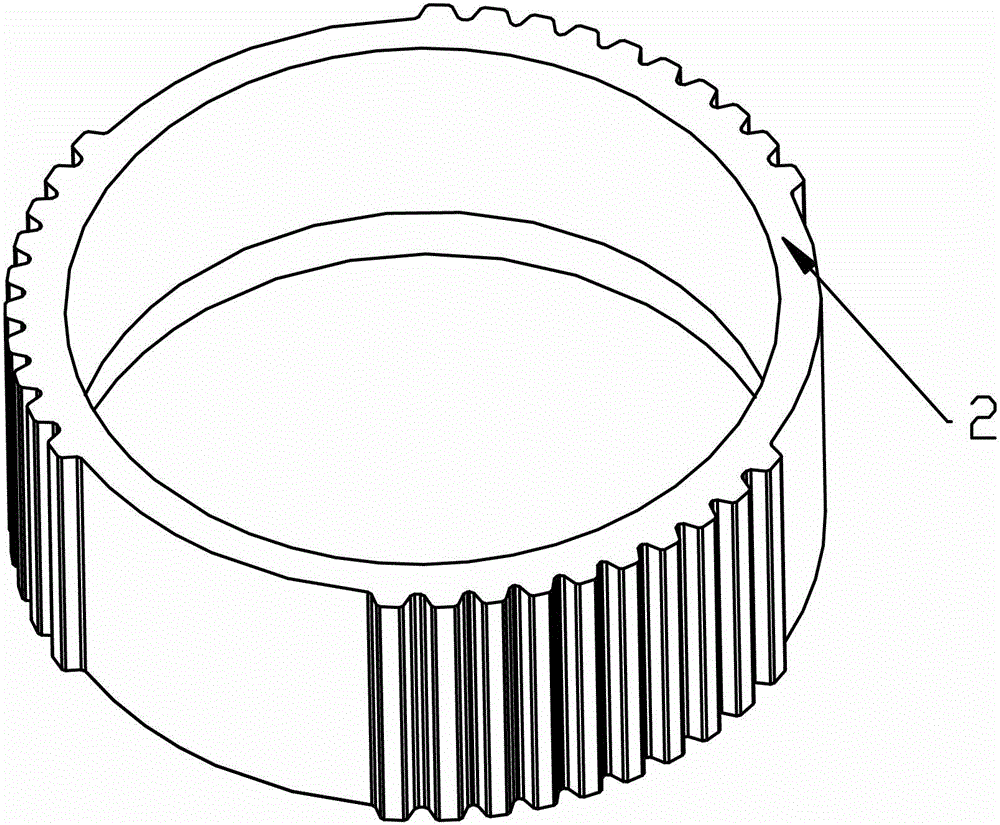

[0037] Such as Figure 1 to Figure 7 As shown, it is a composite mold for fine blanking and deep drawing provided by the embodiment of the present invention, which includes a deep drawing punch 7, a convex and concave die 2, a deep drawing counter plate 1, a fine blanking die 5, and a V-ring blank holder 3 And fine blanking counter pressure plate 6. The deep-drawing counter-press plate 1 and the deep-drawing punch 7 are both cylindrical; the punch-concave die 2 and the fine-blanking counter-press plate 6 are all cylindrical, and the cylindrical outer walls of the punch-concave die 2 and the fine-blanking counter-press plate 6 are provided with three sections (also can The outer wall tooth-shaped section that is multi-segment) evenly spaced; The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com