Robot crus structure capable of imitating human body ankle motions by utilizing pull rods

A technology of robots and pull rods, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of difficult miniaturization, large number of components, damage, etc., and achieve the effect of strengthening stability and simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

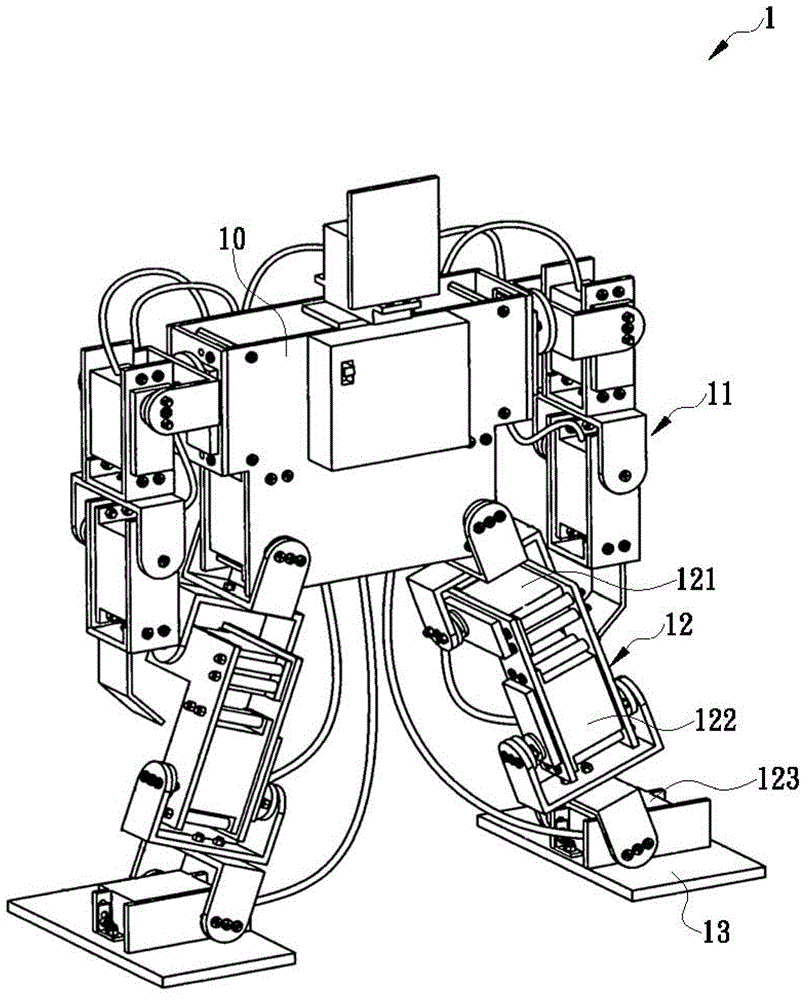

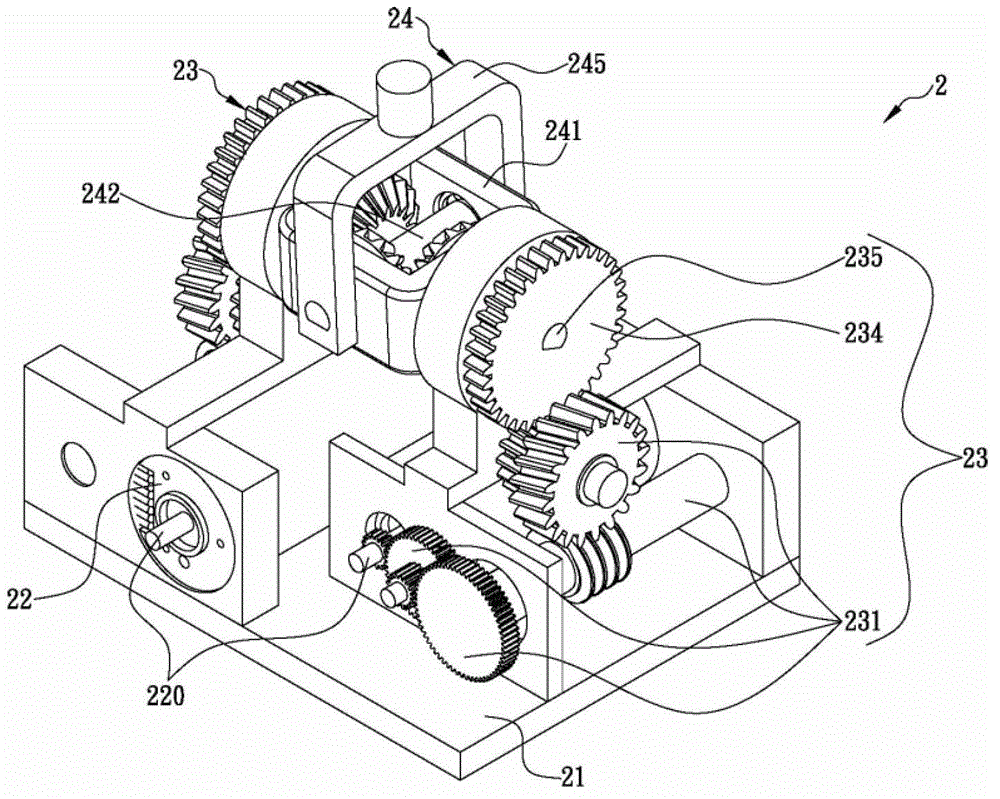

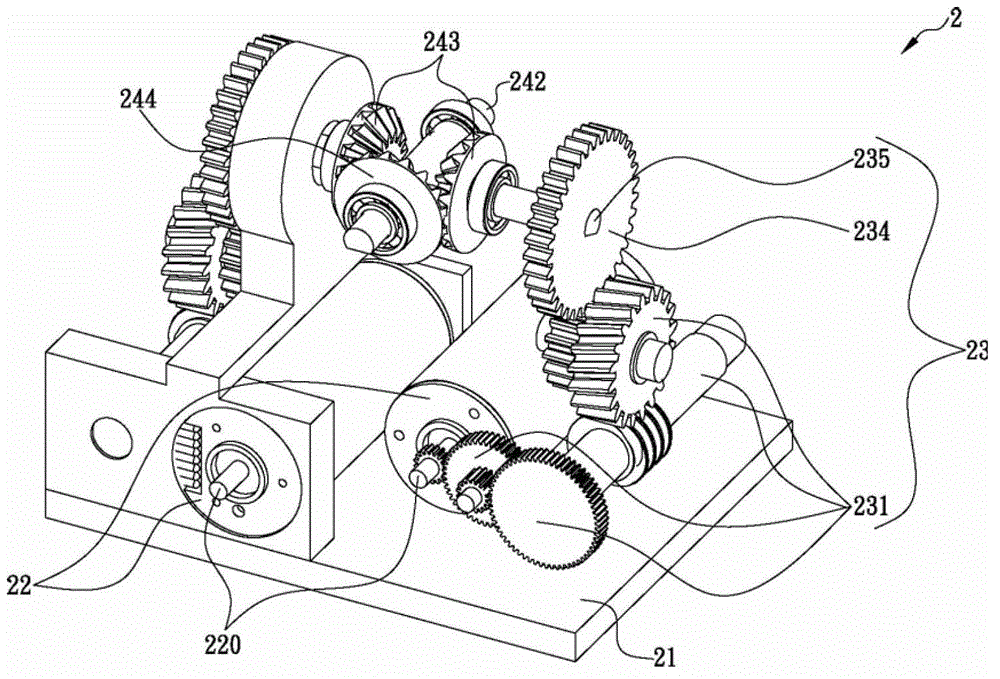

[0032] Such as Figure 4As shown, the present invention uses a pull rod to simulate the movement of the ankle of a robot, which is applied to a robot (not shown in the figure). At least two driving modules are arranged under the knee of the robot, and each driving module has an output shaft The positions correspond to each other, and the robot lower leg structure 4 includes a support frame 41, a foot plate 42, a frame 43, an inner shaft rod 44, a front pull rod 45 and two rear pull rods 46, wherein the support frame 41 is installed on the robot. There are two first pivotal joints 411 below the knee, and the top is provided with two first pivotal joints 411, and a first pivotal joint 412 is opened on each first pivotal joint 411, and the position of each first pivotal joint 412 corresponds to each drive module , in this embodiment, the structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com