C80 autoclaving-free concrete pole production technology

A concrete and pressure-free steaming technology, which is applied in the field of concrete pole production, can solve the problems of high safety requirements for autoclaves, reduction of concrete strength, and damage to concrete structures, so as to achieve good economic and social benefits, reduce energy consumption, The effect of increasing the pause time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

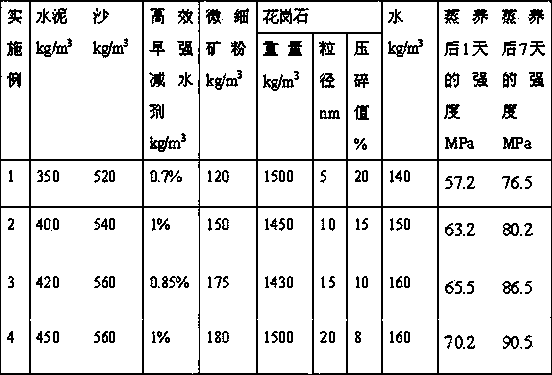

Examples

Embodiment 2

[0032] A C80 non-pressure steamed concrete pole production technology includes the following steps:

[0033] (1) Mixed material: The mixed material adopts the secondary mixing method, that is, first uniformly mix cement, sand, high-activity mineral admixture, high-efficiency early-strength superplasticizer and 30% water, and then add gravel and 70% water Stir for 3 minutes;

[0034] (2) Molding: Pour the mixed material into the electric pole steel mold for centrifugal molding, and take samples to make test blocks at the same time;

[0035] (3) Steam curing: put the pole and the test block into the curing pool for normal pressure steam curing; the steam curing system is to stop at room temperature for 2 hours, and evenly heat up to 85°C in 2 hours, and the heating rate does not exceed 35°C per hour. After 7 hours, the temperature was lowered to 40°C for 30 minutes, and the boiler pressure was maintained at 0.15MPa.

[0036] (4) Testing: Demoulding the test block to test th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com