A kind of acidic cyanide-free copper-tin alloy electroplating solution

A copper-tin alloy and electroplating solution technology, applied in the field of surface treatment, can solve the problems of long-term fogging of electroplating, narrow operating range, low current efficiency, etc., and achieve the effects of uniform and bright appearance, wide current density range, and improved current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An acidic cyanide-free copper-tin alloy electroplating solution with the following formula:

[0030] Hydrochloric acid 50g / L

[0031] Copper chloride 10g / L

[0032] Stannous chloride 10g / L

[0033] OP-92.5g / L

[0034] P-Chlorobenzaldehyde 0.5g / L

[0035] Preparation method: Dissolve copper chloride and stannous chloride in an aqueous hydrochloric acid solution, add dispersant and gloss agent under stirring, stir until completely dissolved, and add water to a constant volume.

[0036] Electroplating operation: the cathode is a copper sheet, the anode is a phosphor copper plate, the pH is less than 1, and the current density is 1A / dm 2 , The temperature is 30 ℃, after 2 minutes of electroplating, a uniform and bright copper-tin alloy is plated on the copper sheet, the thickness is 1μm, and the hardness is 380HV. The appearance of the coating is bright, and the coating is baked at 120°C for 60 minutes without blistering.

Embodiment 2

[0038] An acidic cyanide-free copper-tin alloy electroplating solution with the following formula:

[0039] Hydrochloric acid 75g / L

[0040] Copper chloride 20g / L

[0041] Stannous chloride 20g / L

[0042] OP-105g / L

[0043] P-Chlorobenzaldehyde 0.5g / L

[0044] See Example 1 for the preparation method.

[0045] Electroplating operation: the cathode is a copper sheet, the anode is a phosphor copper plate, the pH is less than 1, and the current density is 0.5A / dm 2 , The temperature is 40 ℃, after 5 minutes of electroplating, a uniform and bright copper-tin alloy is plated on the copper sheet, the thickness is 3μm, and the hardness is 380HV. The appearance of the coating is bright, and the coating is baked at 120°C for 60 minutes without blistering.

Embodiment 3

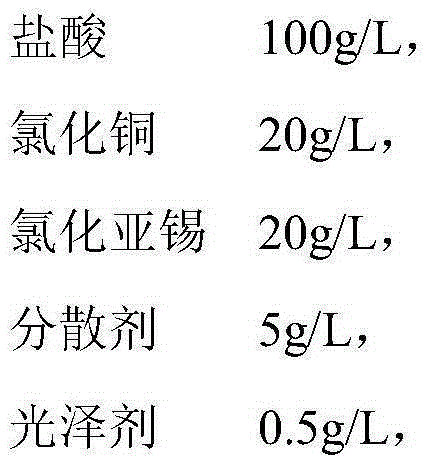

[0047] An acidic cyanide-free copper-tin alloy electroplating solution with the following formula:

[0048] Hydrochloric acid 100g / L

[0049] Copper chloride 15g / L

[0050] Stannous chloride 15g / L

[0051] O-205g / L

[0052] Piperonal 0.5g / L

[0053] See Example 1 for the preparation method.

[0054] Electroplating operation: the cathode is a copper sheet, the anode is a phosphor copper plate, the pH is less than 1, and the current density is 2A / dm 2 , The temperature is 20 ℃, after electroplating for 10 minutes, the copper sheet is plated with a uniform and bright copper-tin alloy with a thickness of 5μm and a hardness of 380HV. The appearance of the coating is bright, and the coating is baked at 120°C for 60 minutes without blistering.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap