Circulating fluidized bed boiler having water cooling reinforcement structure

A technology of circulating fluidized bed and water-cooling column, which is applied in the field of large-scale circulating fluidized bed boilers, can solve the problems of reduced combustion efficiency of boilers and cannot continue to maintain combustion, achieves improved strength, is beneficial to furnace temperature control and heat distribution design, The effect of increasing the heating area in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] While the present invention will be fully described with reference to the accompanying drawings containing preferred embodiments of the invention, it should be understood before proceeding that those skilled in the art may modify the invention described herein while obtaining the technical effects of the present invention. Therefore, it should be understood that the above description is a broad disclosure for those skilled in the art, and its content is not intended to limit the described exemplary embodiments of the present invention.

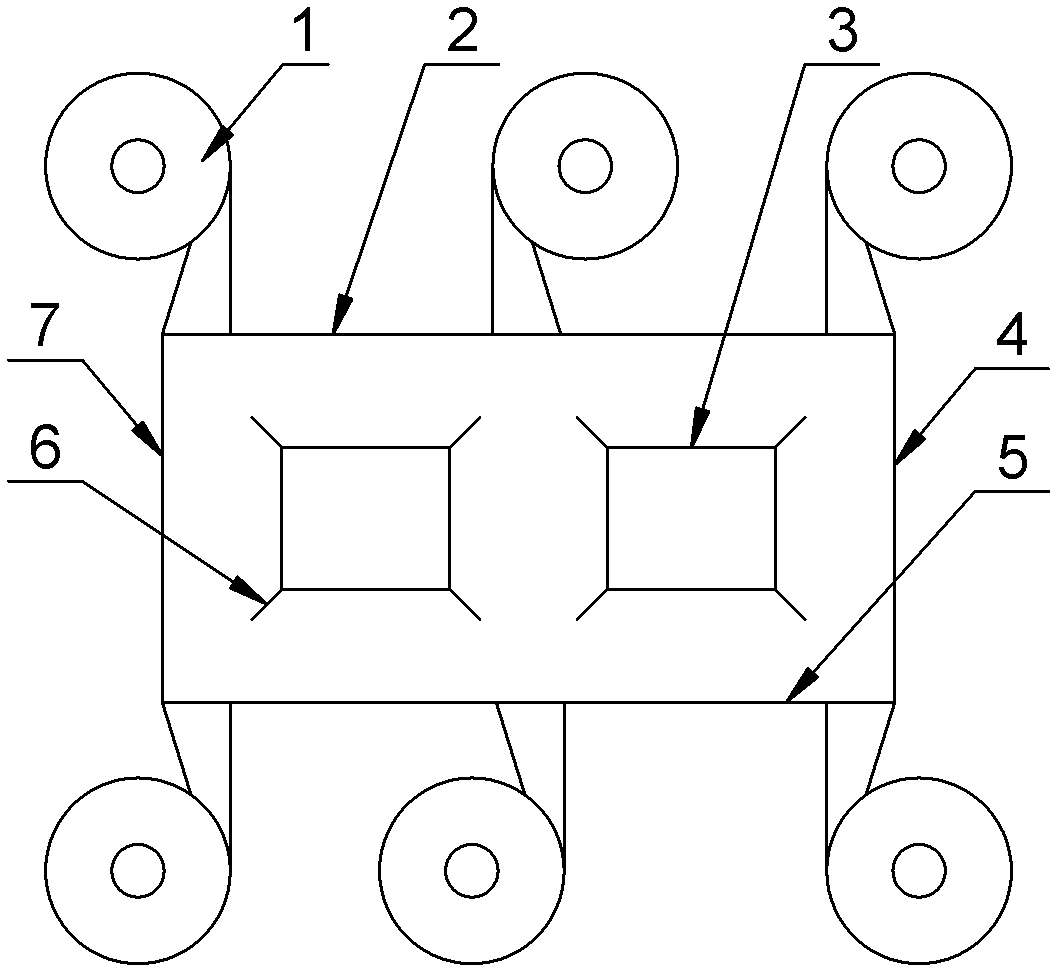

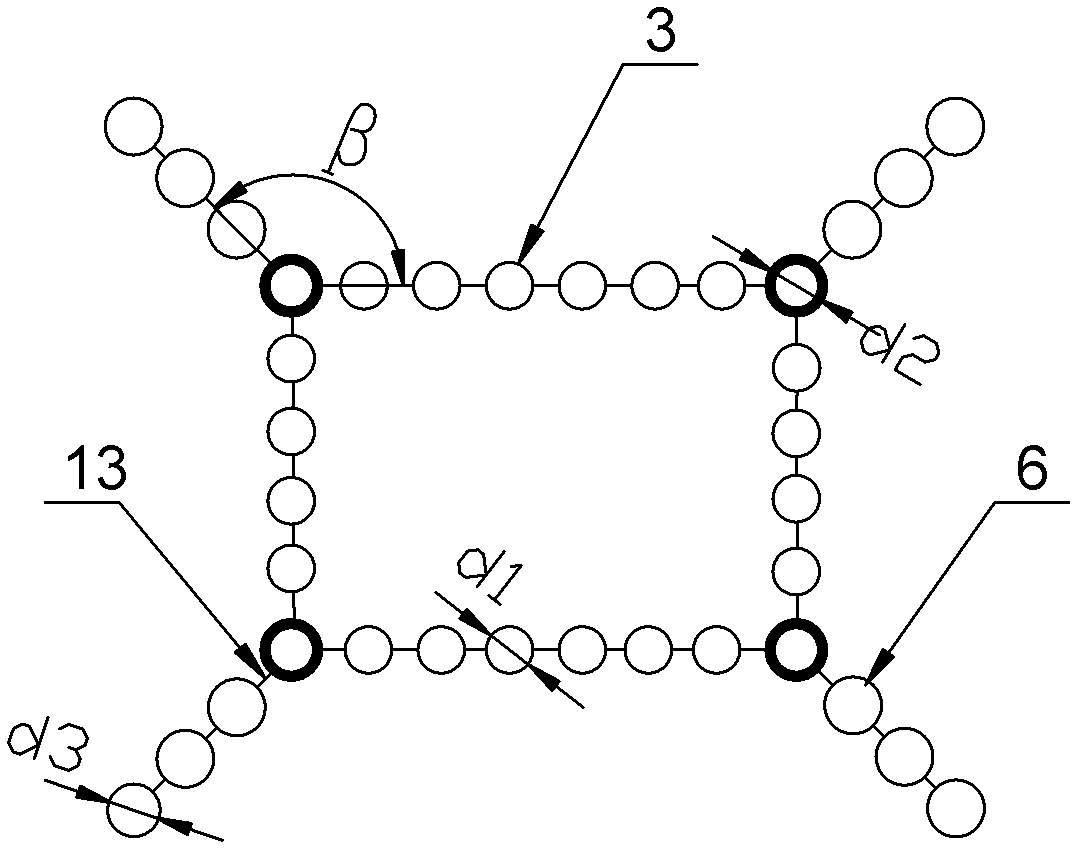

[0025] The invention is used for a circulating fluidized bed boiler in which one or more vertical water cooling columns are arranged between the air distribution plate and the ceiling of the furnace. The water-cooled column is columnar, surrounded by a membrane-type water-cooled wall, and the cross-section is polygonal, such as square, rectangular, regular hexagon, regular octagon, etc.

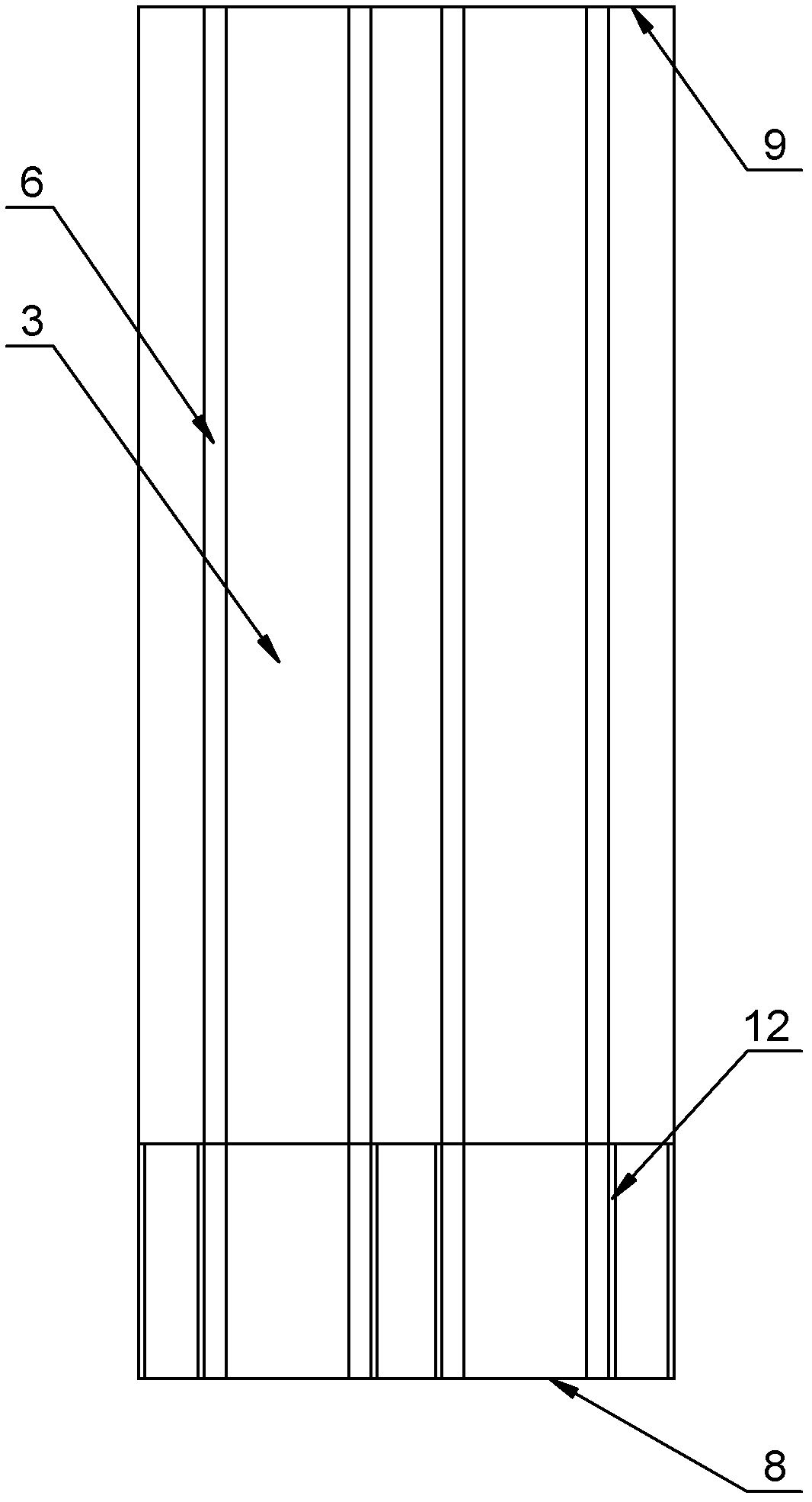

[0026] Such as Figure 1-5 As shown in , the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com