Main steam pressure self-adaptive predictor of generator set of circulating fluidized bed boiler

A technology of circulating fluidized bed and generator set, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, combustion type, etc., and can solve the problems of difficulty in achieving stable control of main steam pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

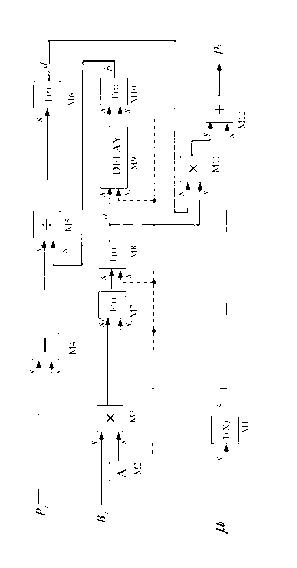

[0008] A main steam pressure adaptive predictor of a circulating fluidized bed boiler generator set, including an addition module, a subtraction module, a multiplication module, a division module, a function module, a first-order inertia module and a delay module, and the input end of the subtraction module M4 the s 1 The main steam pressure of the circulating fluidized bed boiler generator set P t connection, input s of the first function module M1 1 Turbine control valve μ for circulating fluidized bed boiler generator set t Connection, the output terminal of the first function module M1 is respectively connected with the input terminal s of the subtraction module M4 2 and the input s of the addition module M12 2 Connection, the output terminal of the subtraction module M4 and the input terminal s of the division module M5 1 connected, the input s of the first multiplication module M3 1 Boiler coal feed rate with circulating fluidized bed boiler generator set B t is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com