Method for accurately representing material machining strength in cigarette loosening and moisture-regaining process

It is a technique for loosening and reconditioning and characterization. It is applied in the measurement of color/spectral characteristics, etc. It can solve the problems of parameter adjustment and control of the loosening and reconditioning process that cannot be used to make silk threads, and research on unfavorable characteristic process technology, achieving remarkable technical effects and simple and easy operation methods. , the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

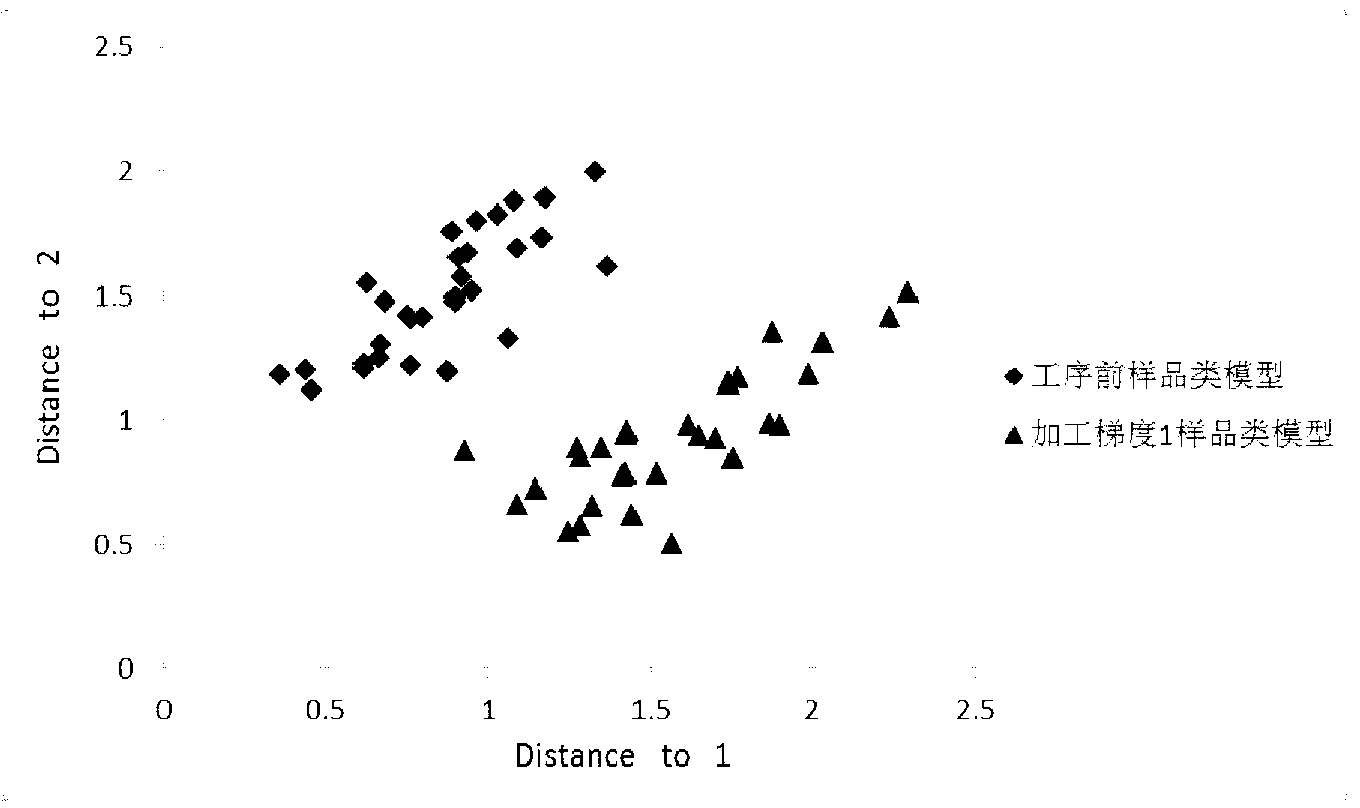

Embodiment 1

[0030] (1) The middle-grade tobacco module was selected as the analysis object, and the tobacco leaf samples before the process were collected as the control samples according to the requirements of the leaf group formula. At the same time, the test was carried out according to the gradient combination of processing parameters listed in Table 1, and the samples of processing gradient 1, processing gradient 2, and processing gradient 3 were taken as test samples after the process. Then the collected control samples and test samples were ground into powder, and equilibrated in a constant temperature and humidity chamber (ambient temperature and humidity: 22°C, 60%RH) for 48 hours to be tested.

[0031] Table 1 Embodiment 1 processing condition setting

[0032]

Process hot air temperature (°C)

Processing Gradient 1

50

[0033] Processing Gradient 2

60

Processing Gradient 3

70

[0034] (2) Select the online near-inf...

Embodiment 2

[0048] (1) Select the high-grade cigarette module as the analysis object, and carry out the test according to the gradient combination of processing parameters listed in Table 5, and the other contents are the same as in Example 1.

[0049] Table 5 embodiment 2 processing condition setting

[0050]

Process hot air temperature (°C)

Drum speed (rpm)

Processing Gradient 1

50

9

Processing Gradient 2

60

8

Processing Gradient 3

70

7

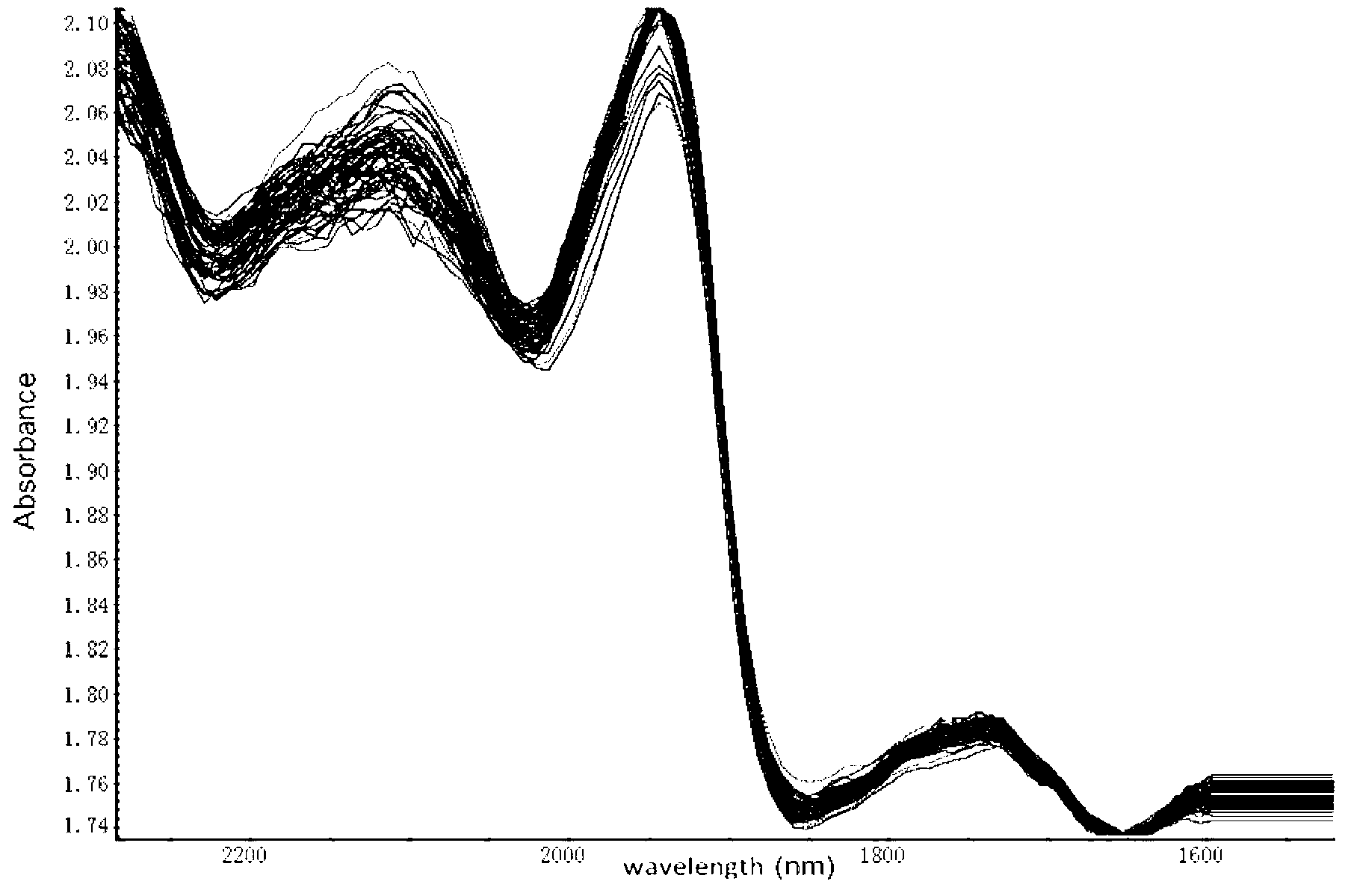

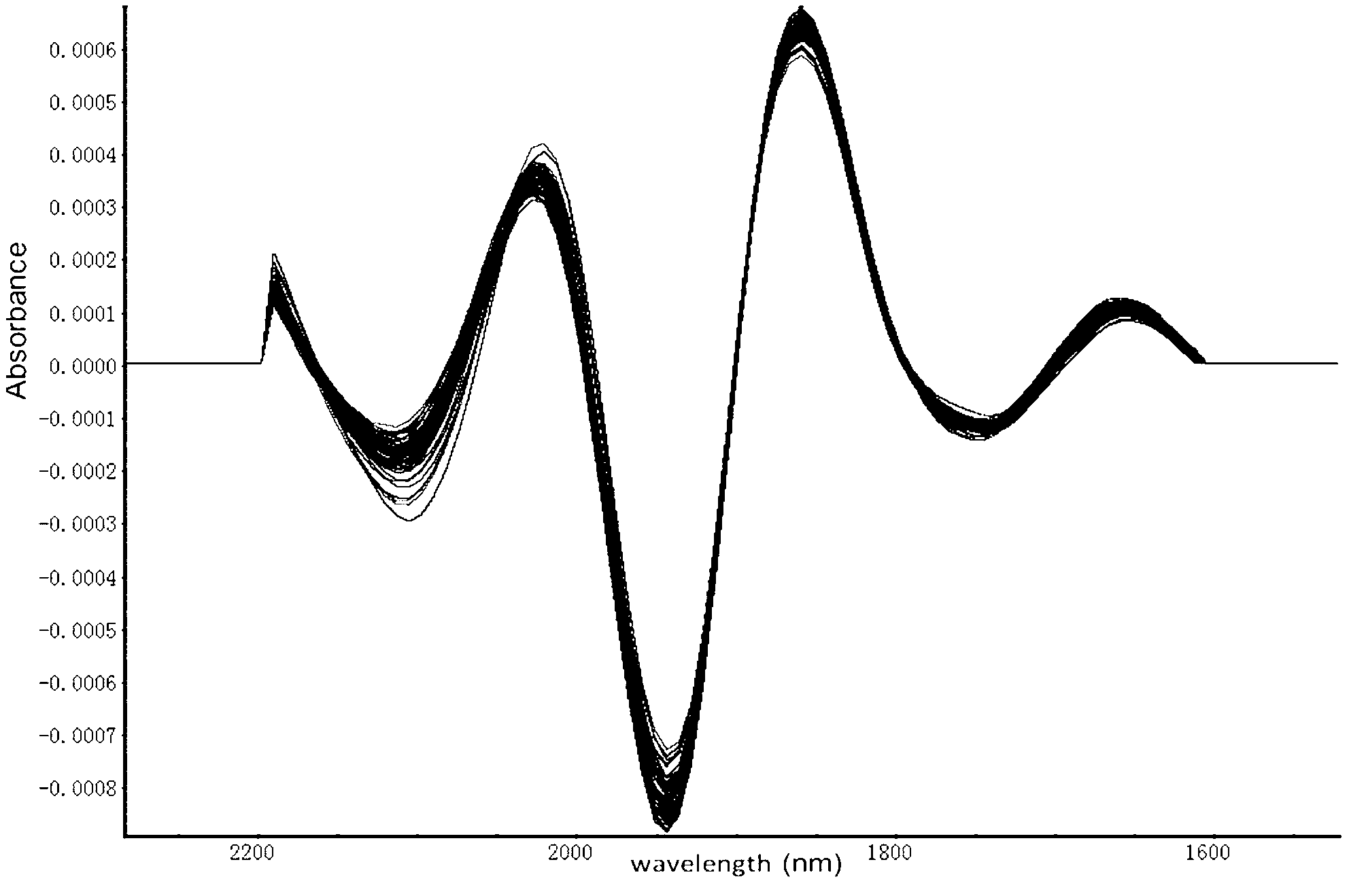

[0051] (2) Select the online near-infrared spectrometer to scan the near-infrared spectrum of the control sample, the processing gradient 1 test sample, the processing gradient 2 test sample, and the processing gradient 3 test sample respectively. Near-infrared spectrum scanning range of each sample: 1400-2300nm, resolution: 4cm -1 , number of scans: 40 times, other content is the same as embodiment 1. The obtained original near-infrared spectrum is shown in Figure 4 shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com