Embedded type touch screen and display device

An embedded touch screen, touch screen technology, applied in instruments, computing, electrical and digital data processing, etc., can solve the problems of dependence, inability to achieve touch operation, and short life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

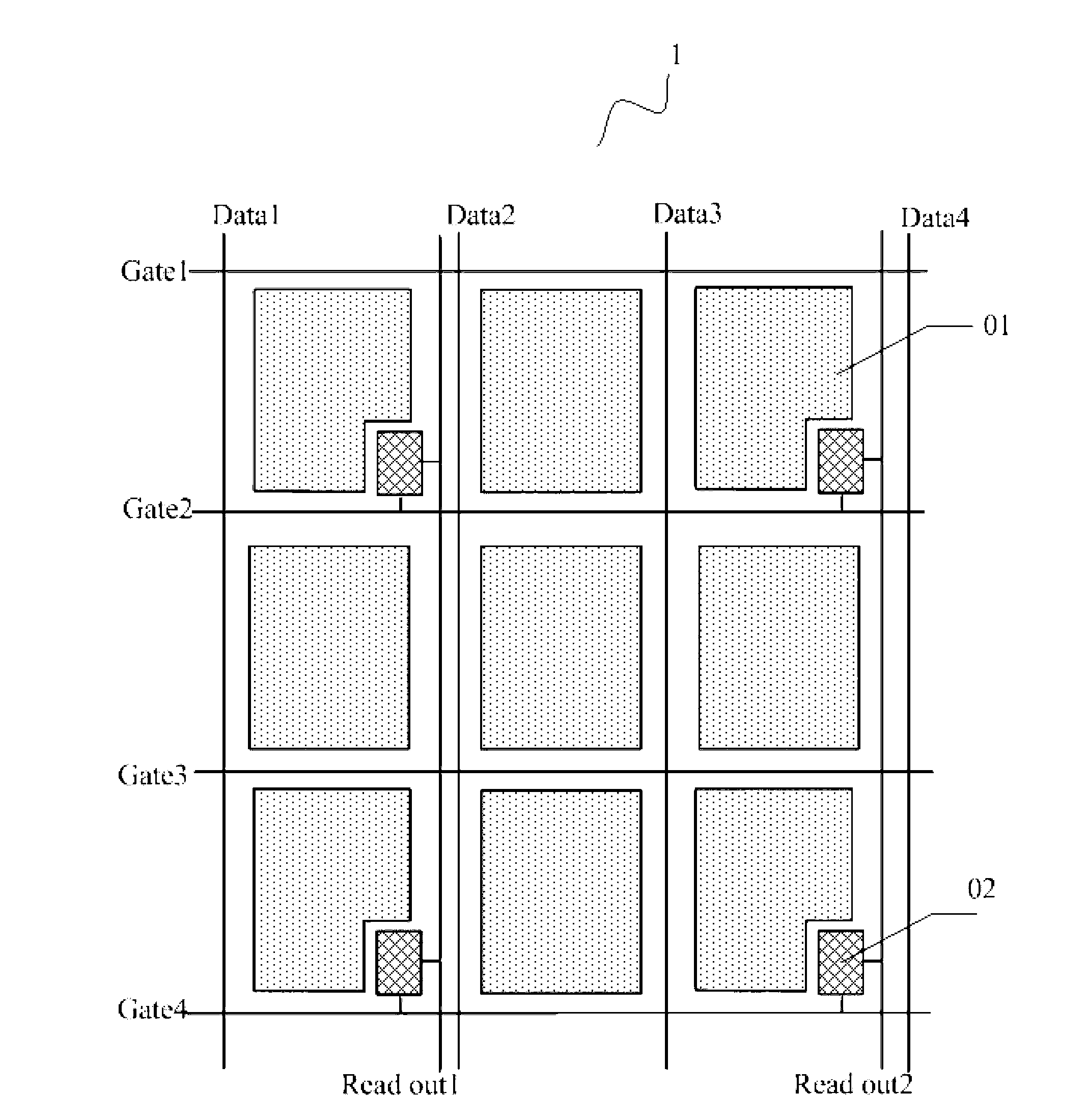

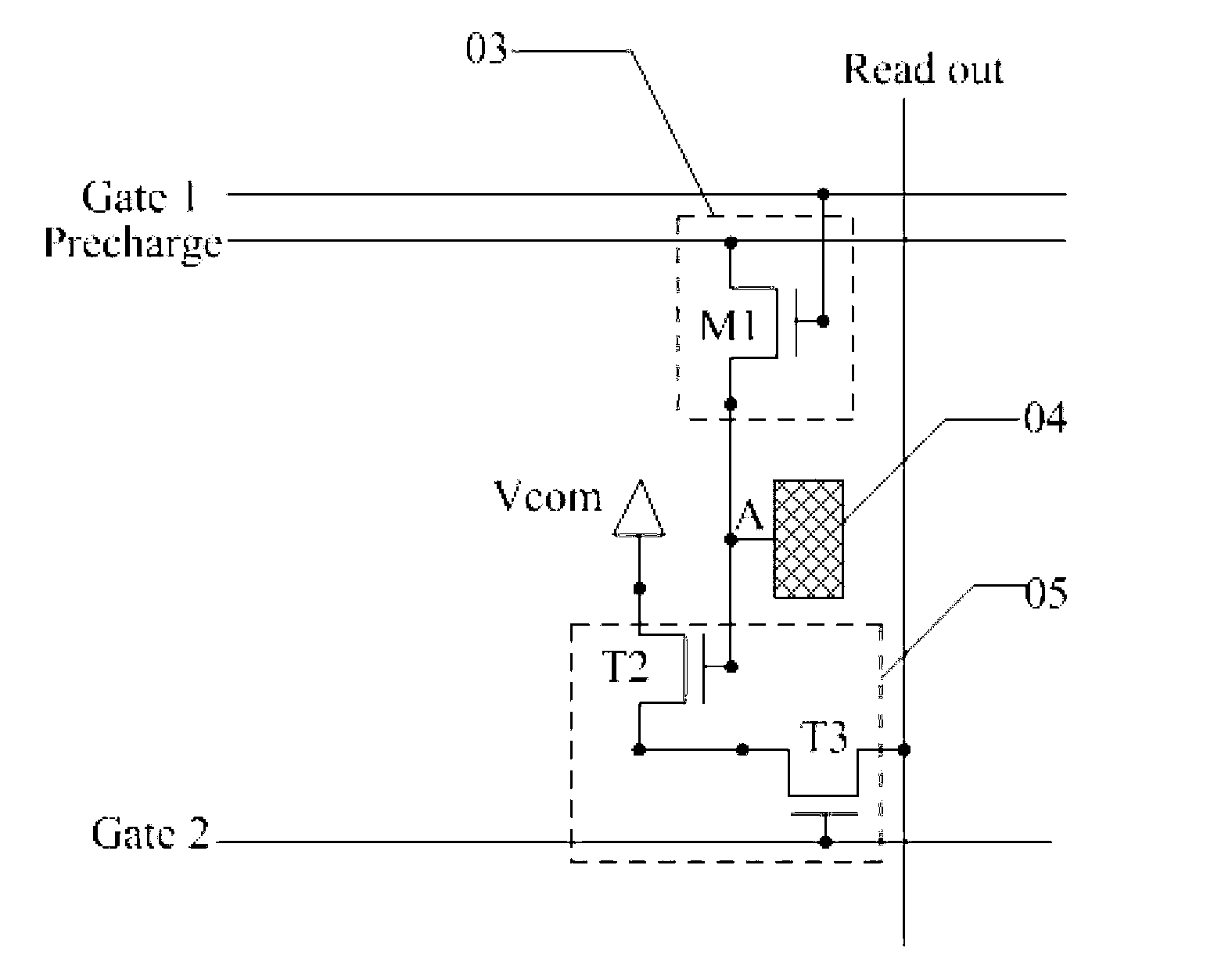

[0035] The array substrate is provided with a plurality of photosensitive scanning lines and a plurality of photosensitive signal lines located between adjacent pixel units in the array substrate. In a specific implementation, the light-sensitive scanning line and the light-sensitive signal line may be arranged at the gap between the pixel units of adjacent rows. Moreover, in order to simplify the wiring on the array substrate, the light-sensitive scan line may be specifically set as at least one gate signal line in the array substrate that is different from the touch scan line. E.g, Figure 3a Gate1 and Gate2 are two adjacent gate signal lines. Gate2 can be used as a touch scan line, Gate1 of the upper row of Gate2 can be used as a photosensitive scan line, and Precharge is a photosensitive signal line. Of course, in specific implementation, the next row of Gate 3 of Gate 2 can also be used as a light-sensitive scanning line, which is not limited here.

[0036] Further, as Fig...

example 2

[0038] A plurality of photosensitive scanning lines located between adjacent pixel units in the array substrate are arranged on the array substrate. In a specific implementation, the light-sensitive scanning line may be arranged at the gap between the pixel units of adjacent rows. Moreover, in order to simplify the wiring on the array substrate, the light-sensitive scan line may be specifically set as at least one gate signal line in the array substrate that is different from the touch scan line. E.g, Figure 3b Gate1 and Gate2 are two adjacent gate signal lines. Gate2 can be used as a touch scan line, and Gate1 in the upper row of Gate2 can be used as a photosensitive scan line. Of course, in specific implementation, the next row of Gate 3 of Gate 2 can also be used as a light-sensitive scanning line, which is not limited here. .

[0039] Such as Figure 3b As shown, the photosensitive subunit 03 includes a photosensitive transistor M1; wherein the gate and source of the photo...

example 3

[0041] A plurality of photosensitive scanning lines located between adjacent pixel units in the array substrate are arranged on the array substrate. In a specific implementation, the light-sensitive scanning line may be arranged at the gap between the pixel units of adjacent rows. Moreover, in order to simplify the wiring on the array substrate, the light-sensitive scan line may be specifically set as at least one gate signal line in the array substrate that is different from the touch scan line. E.g, Figure 3c Gate1 and Gate2 are two adjacent gate signal lines. Gate2 can be used as a touch scan line, and Gate1 of the upper row of Gate2 can be used as a light-sensitive scan line. Of course, in specific implementation, the next row of Gate 3 of Gate 2 can also be used as a light-sensitive scanning line, which is not limited here.

[0042] Such as Figure 3c As shown, the photosensitive subunit 03 includes a photosensitive transistor M1 and a first transistor T1; wherein, the gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com