Closed type high-voltage coil and manufacturing method thereof

A high-voltage coil, closed technology, applied in the direction of coil manufacturing, coils, electrical components, etc., can solve the problems of cleaning the air and impurities between the coils and the breakdown of high-voltage coils, so as to eliminate the flashover phenomenon and improve the durability pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

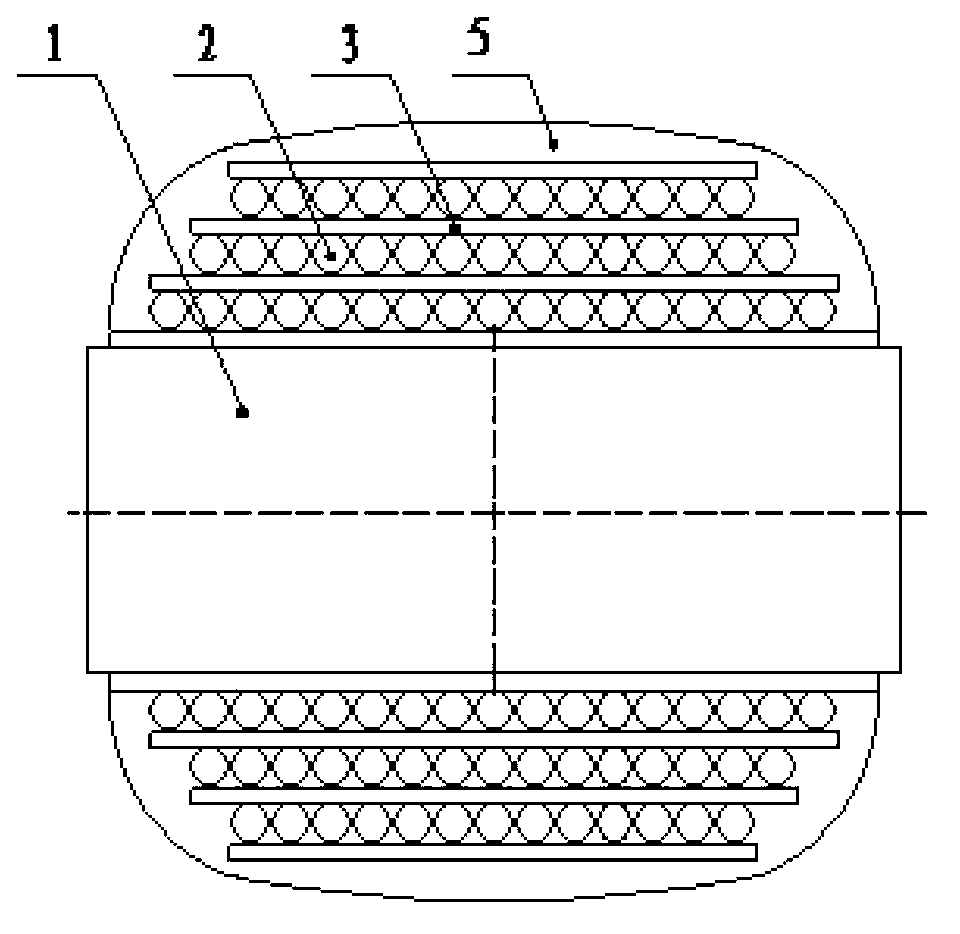

[0026] like image 3 As shown, the present invention includes a coil frame 1, a coil wire 2, an insulating layer 3 between wires, and a sealing layer 5, and the sealing layer 5 seals the coil wire 2 and the insulating layer 3 between wires as a whole, and the sealing layer 5 The material is quartz epoxy resin;

[0027] The material ratio of the sealing layer 5 is by weight: quartz: epoxy resin=1.5:1;

[0028] The invention also discloses a method for manufacturing the enclosed high-voltage coil, the steps are as follows:

[0029] (1) Processing of high-voltage wire package:

[0030] (1). After the high-voltage coil is wound, put it into the infusion tire. The membrane wall should be coated with a layer of silicone grease release agent in advance. The coil lead-out wire can be soldered with multiple strands of soft wire; 95°C, the time is based on the insulation resistance test method for insulation strength testing, that is, to measure the insulation resistance between the ...

Embodiment 2

[0041] like image 3 As shown, the present invention includes a coil frame 1, a coil wire 2, an insulating layer 3 between wires, and a sealing layer 5, and the sealing layer 5 seals the coil wire 2 and the insulating layer 3 between wires as a whole, and the sealing layer 5 The material is quartz epoxy resin;

[0042] The material ratio of the sealing layer 5 is by weight: quartz: epoxy resin=2.5:1;

[0043] The invention also discloses a method for manufacturing the enclosed high-voltage coil, the steps are as follows:

[0044] (1) Processing of high-voltage wire package:

[0045] (1). After the high-voltage coil is wound, put it into the infusion tire. The membrane wall should be coated with a layer of silicone grease release agent in advance. The coil lead-out wire can be soldered with multiple strands of soft wire; 90°C, the time is based on the insulation resistance test method for insulation strength testing, that is, to measure the insulation resistance between the ...

Embodiment 3

[0056] like image 3 As shown, the present invention includes a coil frame 1, a coil wire 2, an insulating layer 3 between wires, and a sealing layer 5, and the sealing layer 5 seals the coil wire 2 and the insulating layer 3 between wires as a whole, and the sealing layer 5 The material is quartz epoxy resin;

[0057] The material ratio of the sealing layer 5 is by weight: quartz: epoxy resin=2:1;

[0058] The invention also discloses a method for manufacturing the enclosed high-voltage coil, the steps are as follows:

[0059] (1) Processing of high-voltage wire package:

[0060] (1). After the high-voltage coil is wound, put it into the infusion tire. The membrane wall should be coated with a layer of silicone grease release agent in advance. The coil lead-out wire can be soldered with multiple strands of soft wire; 90°C, the time is based on the insulation resistance test method for insulation strength testing, that is, to measure the insulation resistance between the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com