Wafer pre-locating device based on machine vision and method thereof

A pre-positioning device and machine vision technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of polluted wafers, expensive, complex cost of optical alignment structures, etc., and achieve simple system structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

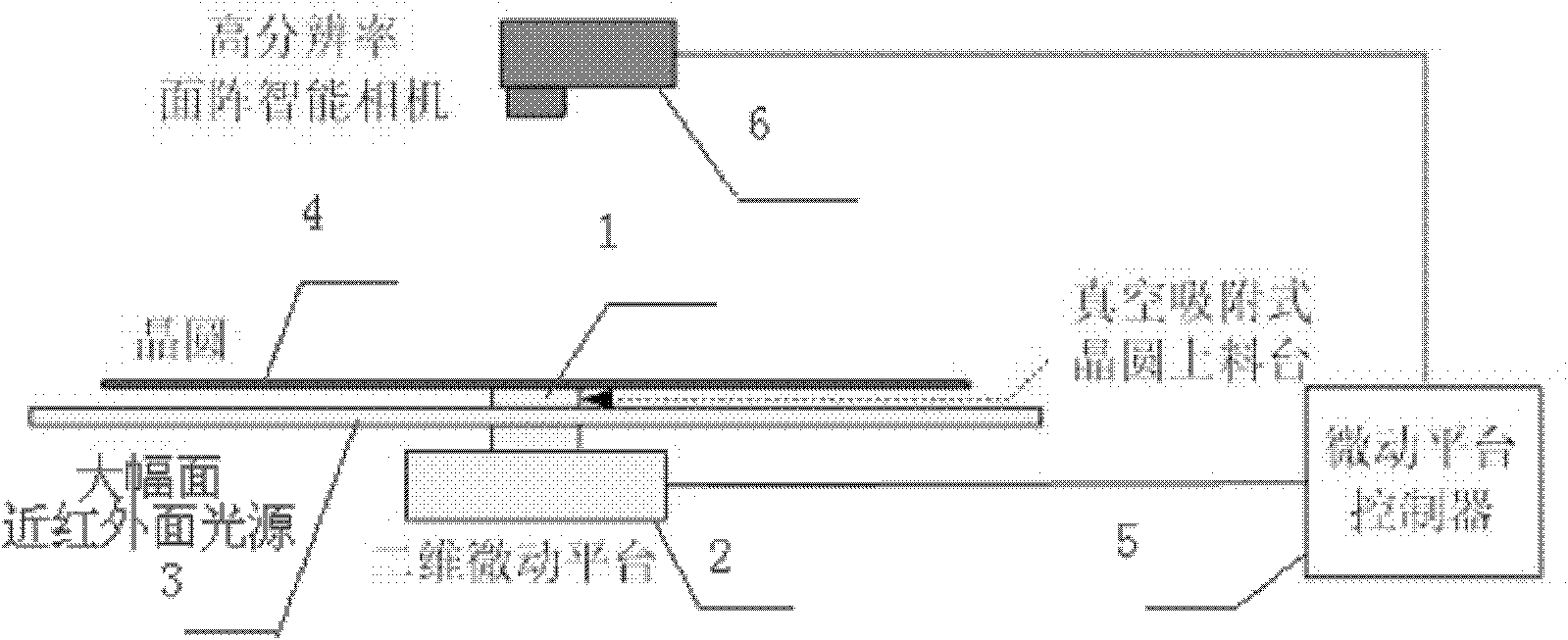

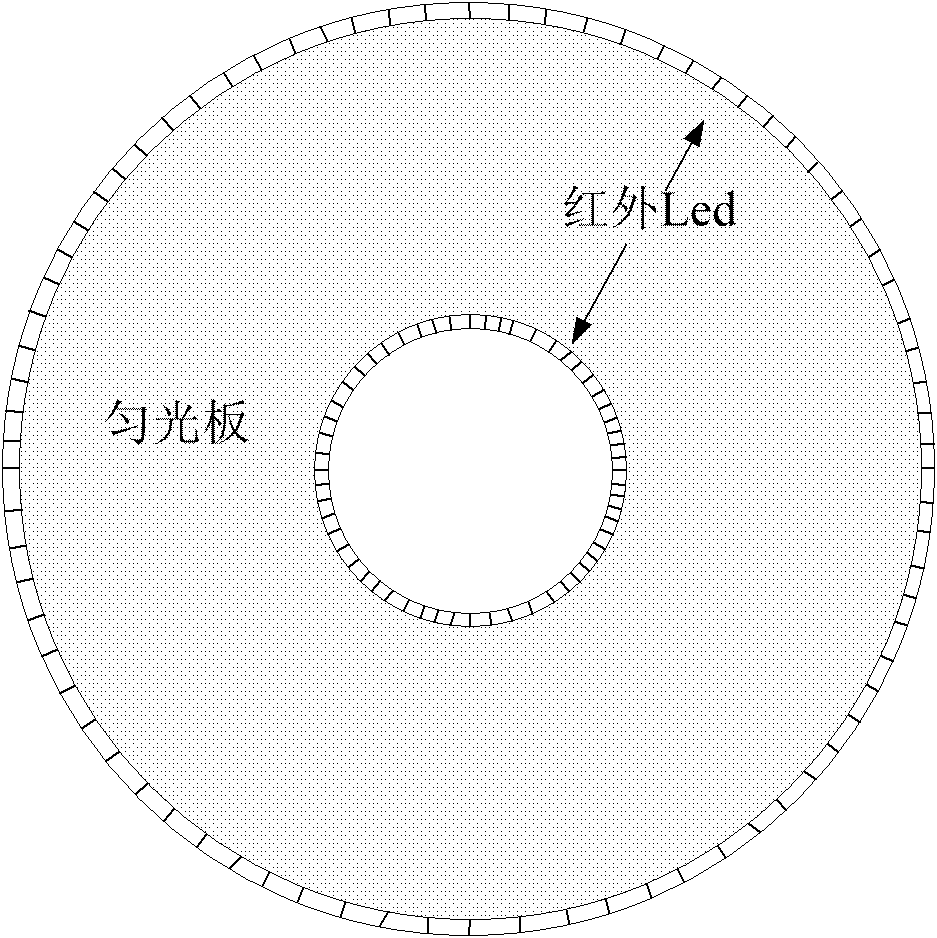

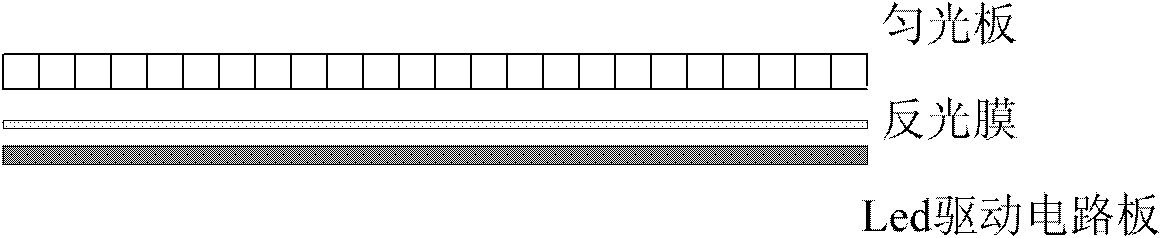

[0030] The wafer pre-positioning device based on machine vision proposed by the present invention includes a vacuum adsorption wafer loading platform, a high-resolution area array smart camera, a large-format infrared light source, and a high-precision two-dimensional micro-motion platform. The pre-positioning method is to first use a high-resolution area array smart camera as a sensor to image the wafer on the loading table, then extract the edge of the wafer through a high-precision edge detection algorithm, and use the least squares algorithm to fit the coordinates of its center, and finally The difference between the current position coordinates of the center of the circle and the reference position coordinates is used as feedback to drive the two-dimensional micro-motion platform, and the wafer position is adjusted to reach the reference p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com