Cigarette filter rod provided with natural mineral and plant fiber composite additive

A technology of composite additives and plant fibers, which is applied in the field of cigarette tip sticks, can solve problems such as unfavorable cigarette smoking, achieve the effects of reducing the content of HCN, ensuring the quality of smoking, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

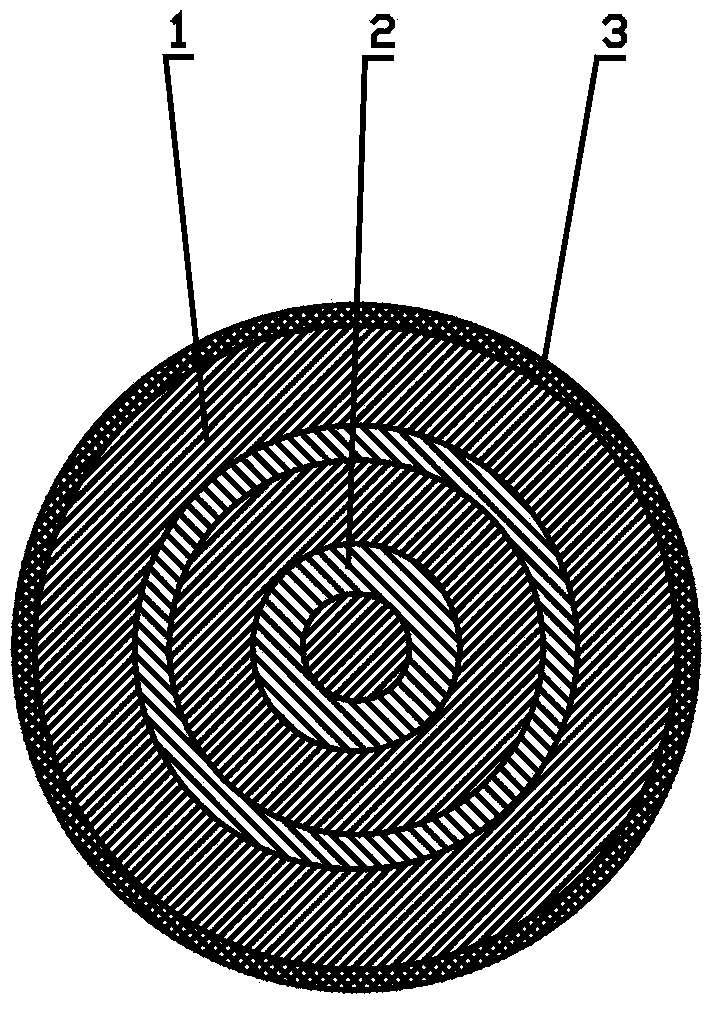

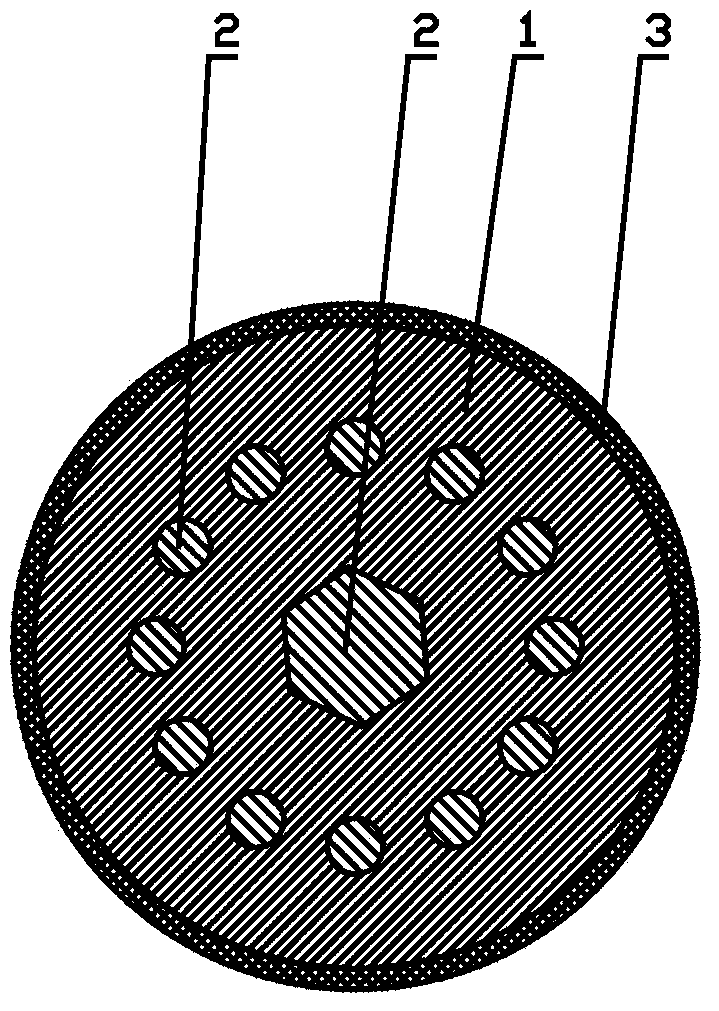

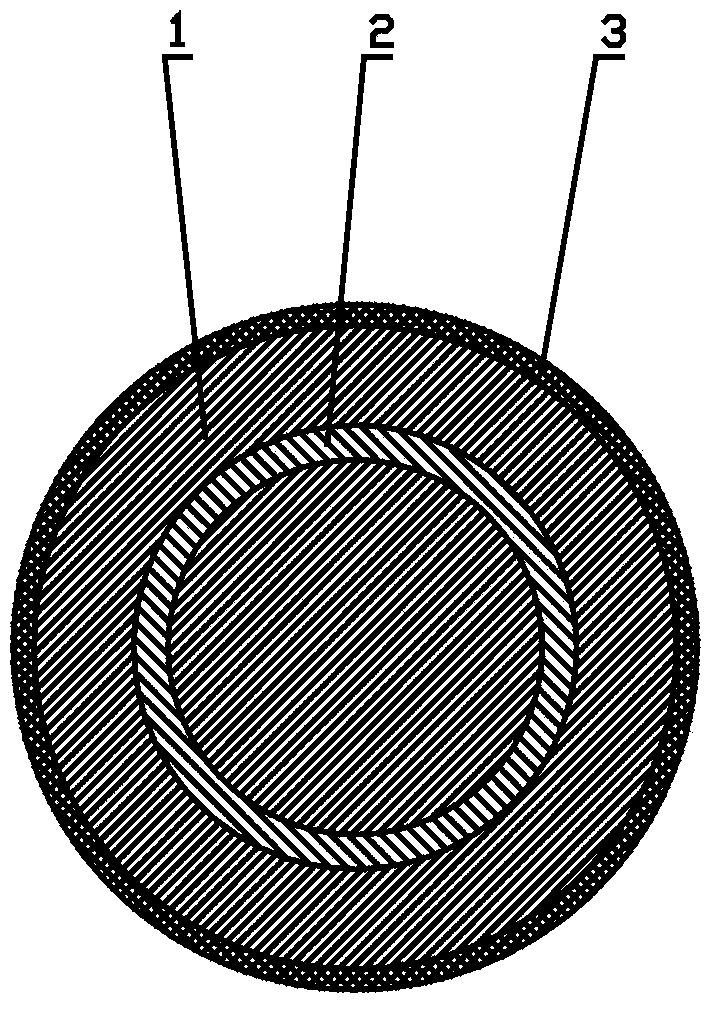

Image

Examples

Embodiment 1

[0028] (1) Preparation of composite additives: 200 grams of Qibingshi powder with a particle size of 50 nm obtained by pulverizing the Qibingshi; Describe 2.9 kilograms of acacia bark fiber powders and mix into composite additive.

[0029] (2) Surface treatment of composite additives: Take 3 kg of composite additives, put them in 6 kg of 70% (weight percent) ethanol, ultrasonically disperse them for 20 minutes, put them in a constant temperature tank at 30°C and stir them for 20 minutes; add 450 2 grams of chelated lactate titanium salt, stirred for 2 hours; after standing for 8 hours, the solution was layered, and the lower layer powder was taken out, dried and ground to 50nm, which was the composite additive for surface modification, sealed for later use;

[0030] (3) Prepare the blended spinning tow of composite additive and cellulose acetate: after blending 2 kilograms of the surface-modified composite additive obtained in step (2) with 100 kilograms of conventional cigare...

Embodiment 2

[0033] (1) Preparation of composite additives: pulverize the strange ice stone to obtain 200 grams of the strange ice stone powder with a particle size of 100 nm; grind the bark of Albizia Julibrissin to obtain 3.5 kg of the fiber powder of the bark of Albizia julienne with a particle size of 100 nm; take 100 grams of the strange ice stone powder and the Describe 3 kilograms of acacia bark fiber powders and mix into composite additive.

[0034] (2) Surface treatment of composite additives: Take 3.1 kg of composite additives, place them in 9.3 kg of 75% (weight percent) ethanol, ultrasonically disperse them for 30 minutes, and put them in a constant temperature tank at 40°C for 30 minutes; add 868 grams of chelated lactate titanium salt were stirred for 3 hours; after standing for 8 hours, the solution was layered, the lower layer powder was taken out, dried and ground to 100nm, which was the composite additive for surface modification, sealed for later use;

[0035] (3) Prepar...

Embodiment 3

[0038] (1) Preparation of composite additives: 200 grams of Qibingshi powder with a particle size of 150 nm obtained by pulverizing the Qibingshi; Describe 3 kilograms of acacia bark fiber powders and mix into composite additive.

[0039] (2) Surface treatment of composite additives: Take 3.2 kg of composite additives, put them in 9.6 kg of 80% (weight percent) ethanol, ultrasonically disperse them for 40 minutes, then put them in a constant temperature bath at 50°C and stir for 40 minutes; add 1.02 Kg of chelated titanium lactate, stirred for 4 hours; after standing for 9 hours, the solution was layered, the lower layer of powder was taken out, dried and ground to 150nm, which was the composite additive for surface modification, sealed for later use;

[0040] (3) Prepare the blended spinning tow of composite additive and cellulose acetate: after blending 4 kilograms of surface-modified composite additives obtained in step (2) with 320 kilograms of conventional cigarette tip r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com