Low-smoke density plastic composition and its preparation method and use

A technology of plastic composition and smoke density, applied in the polymer field, can solve the problems of limited application system of smoke suppressant, cannot reduce smoke density, etc., and achieve the effects of low smoke density, reduction of CO ratio, and smoke suppression CO ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

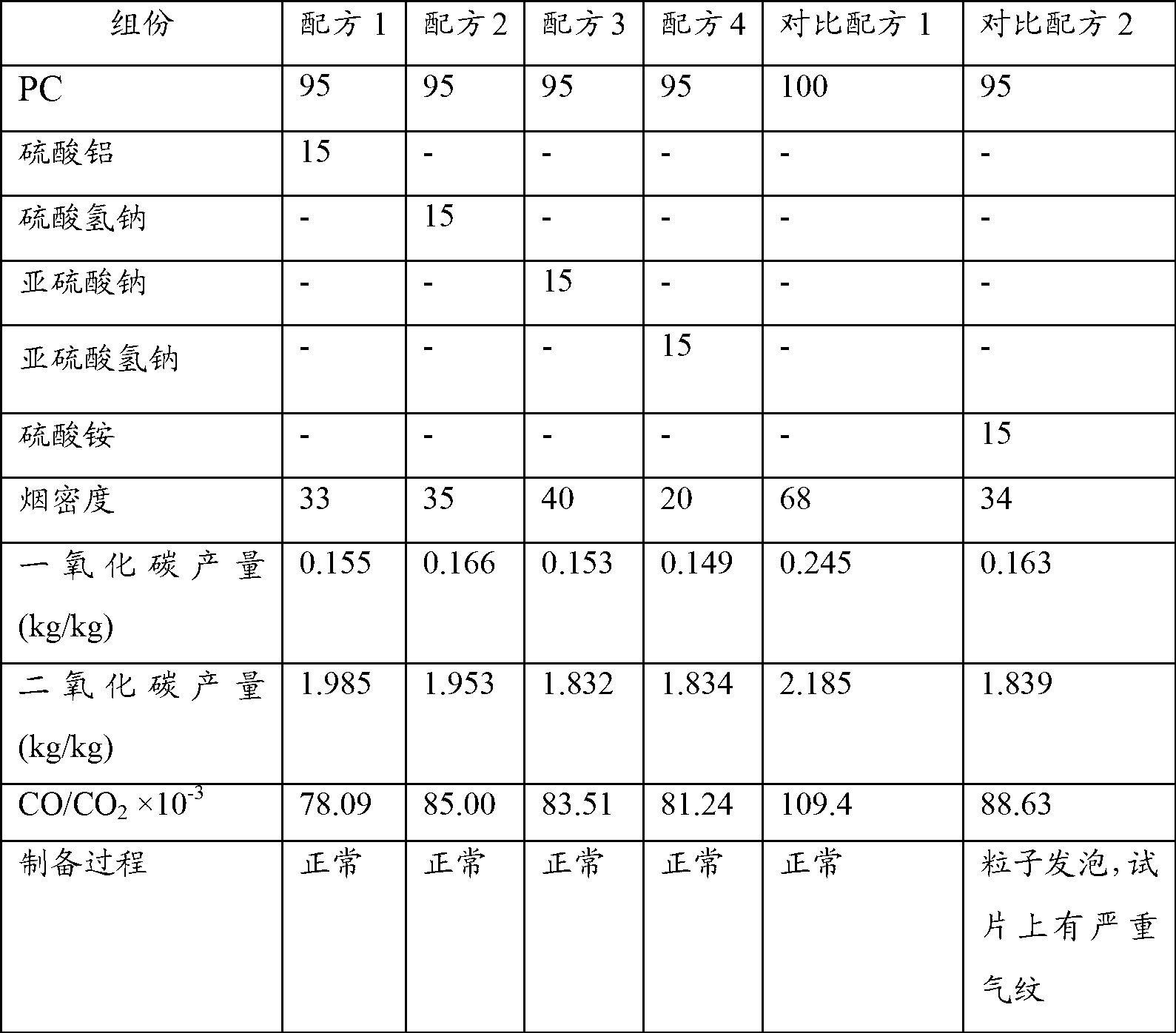

Examples

preparation example Construction

[0039] The preparation of plastic composition among the embodiment 1~7 is carried out as follows:

[0040] The thermosetting samples are prepared by adding resin, curing agent, and smoke suppressant to the container, stirring and mixing at high speed, pouring into a specific sheet metal mold, and heating and curing some types of samples.

[0041] The thermoplastic samples are prepared by mixing the resin with the smoke suppressant, extruding and granulating the resin at the processing temperature of the resin through a twin-screw extruder, and molding it into a sample of a specified size with an injection molding machine.

Embodiment 1

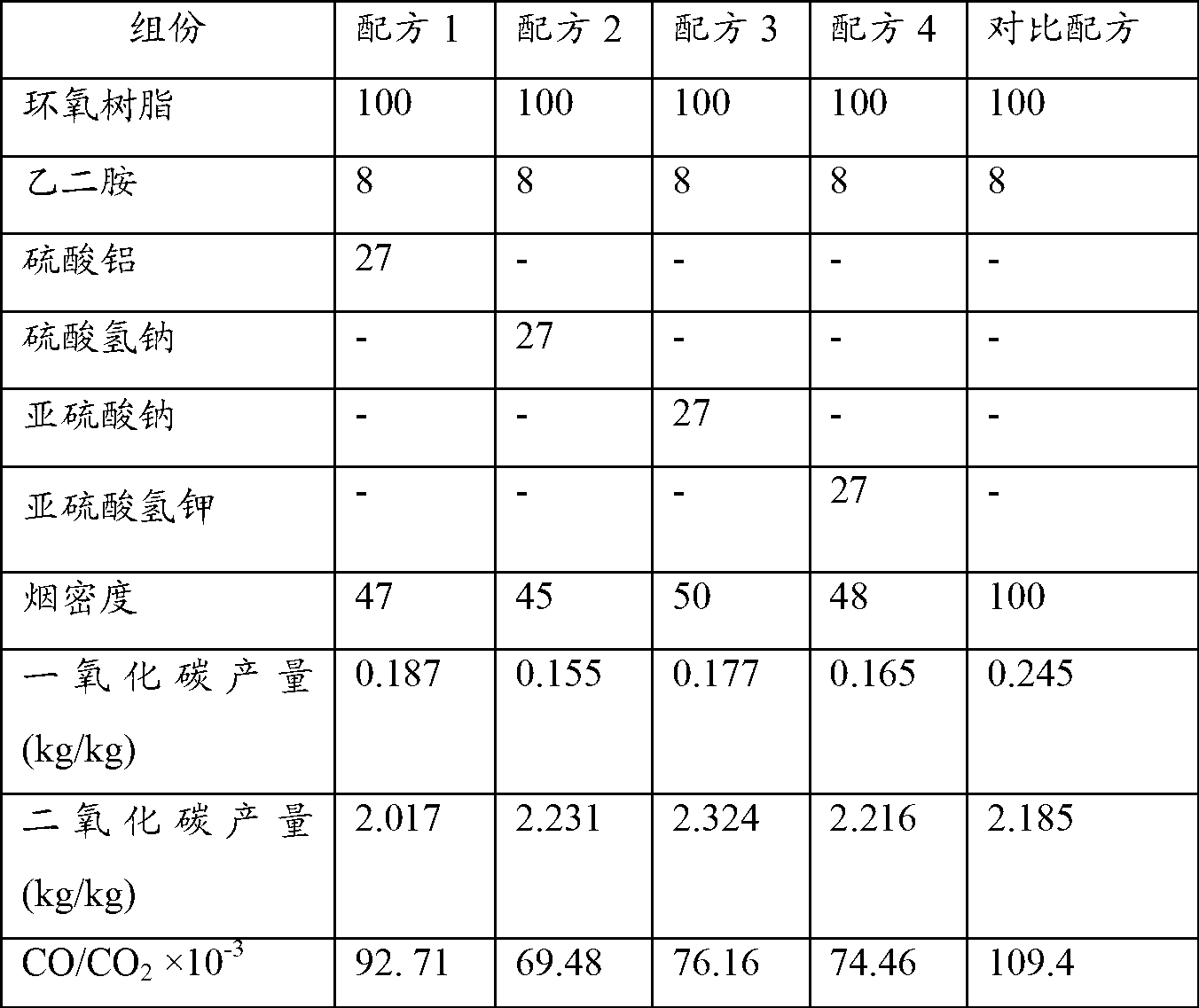

[0042] Embodiment 1 low smoke density epoxy resin

[0043] According to the ratio in Table 1, the low smoke density epoxy resin described in Example 1 was prepared.

[0044] Table 1

[0045]

Embodiment 2

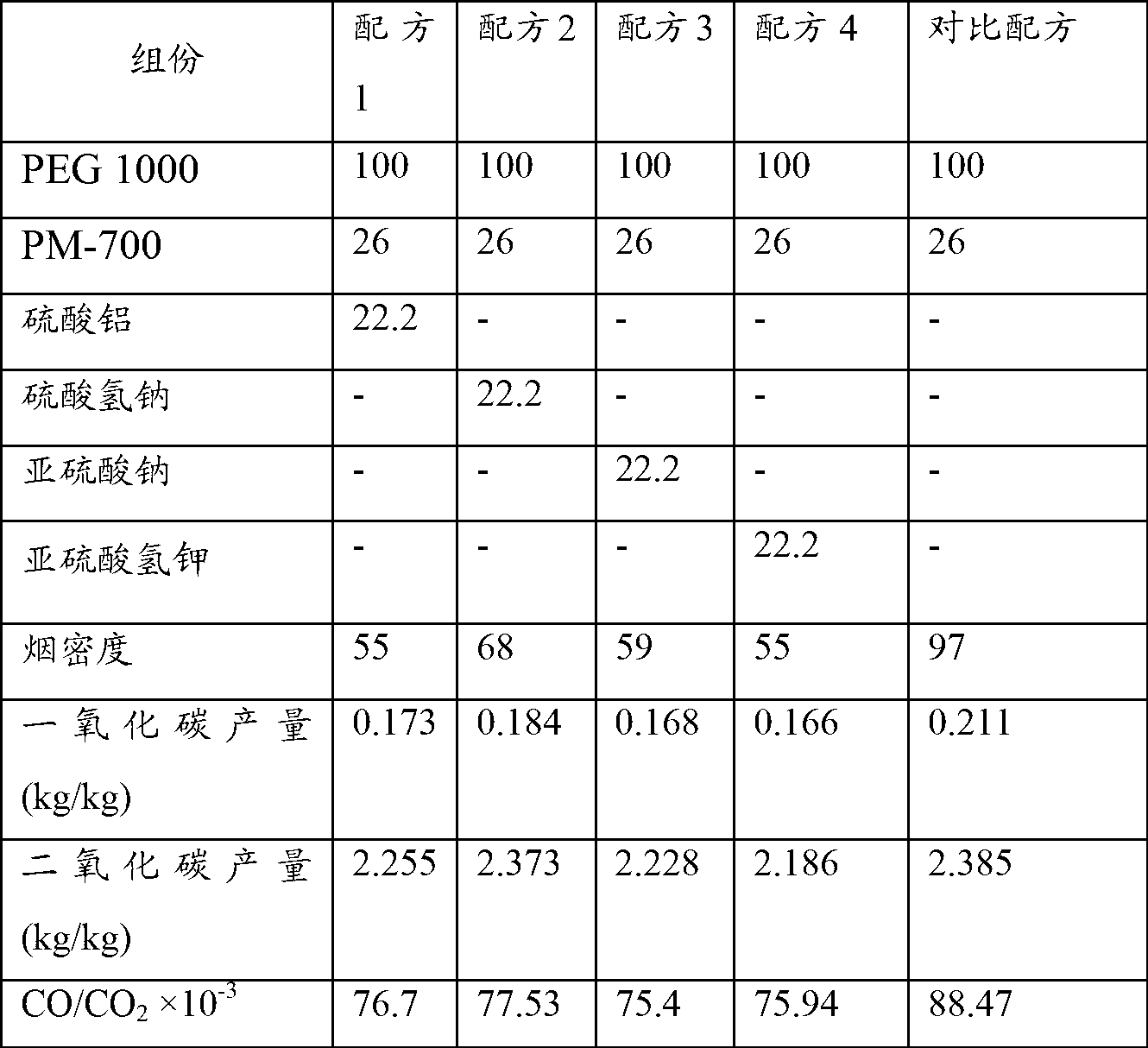

[0046] Example 2 Low Smoke Density Polyurethane

[0047] According to the ratio in Table 2, the low-smoke density polyurethane described in Example 2 was prepared.

[0048] Table 2

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com