Air and gas two-heat-accumulation heating furnace

An air gas and heating furnace technology, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of unstable furnace pressure, heating furnace operation, affecting the quality of hot-rolled products, and difficult to remove oxide scales, etc., to achieve optimization Effect of heating and operation stability, stable pressure, effect of smooth heating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

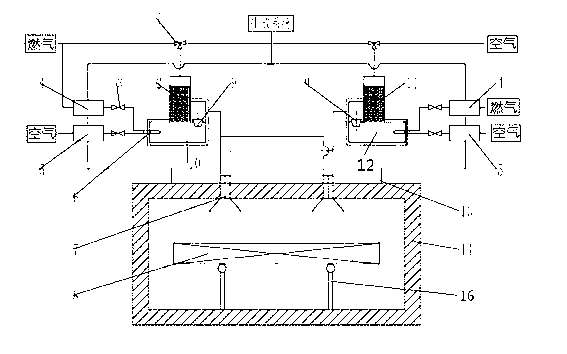

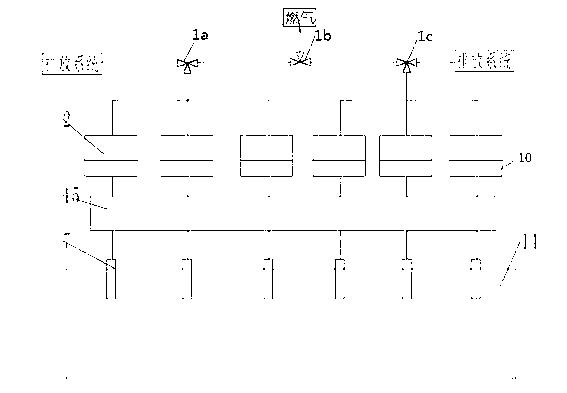

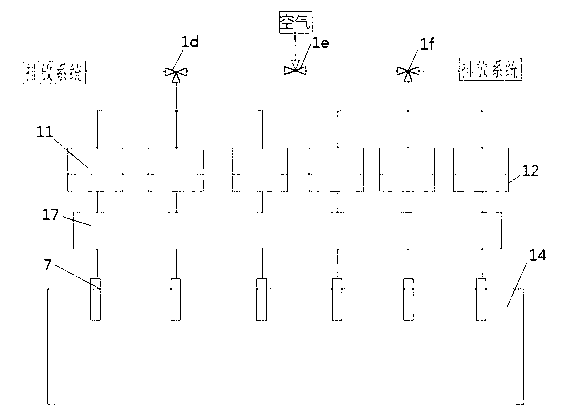

[0014] Air gas double regenerative heating furnace of the present invention, as figure 1 , figure 2 , image 3 As shown, it includes heating furnace 14, 6 gas heat accumulators 2, 6 air heat accumulators 11, gas heat exchanger 4, gas gas collection chamber 15, air gas collection chamber and air heat exchanger 5. There is a flat flame burner 7 on the top of the heating furnace, a billet support 16 on the bottom of the heating furnace, and a flue gas outlet 13 on one side of the heating furnace. The steel billet support is a water cooling mechanism support, and the steel billet 8 is placed on the steel billet support. The gas heat accumulator is provided with a gas heat storage combustion chamber 10, the air heat accumulator is provided with an air heat storage combustion chamber 12, and the gas heat storage combustion chamber and the air heat storage combustion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com