Oil-gas separation part structure

A technology for separating components and components, which is applied in the direction of separation methods, dispersed particle separation, variable capacity pump components, etc., can solve the problems of poor use effect, inability to completely separate oil and gas, and short passage paths, etc., and achieve simple structure, improve gas Liquid recirculation effect, effect of increasing gas recirculation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

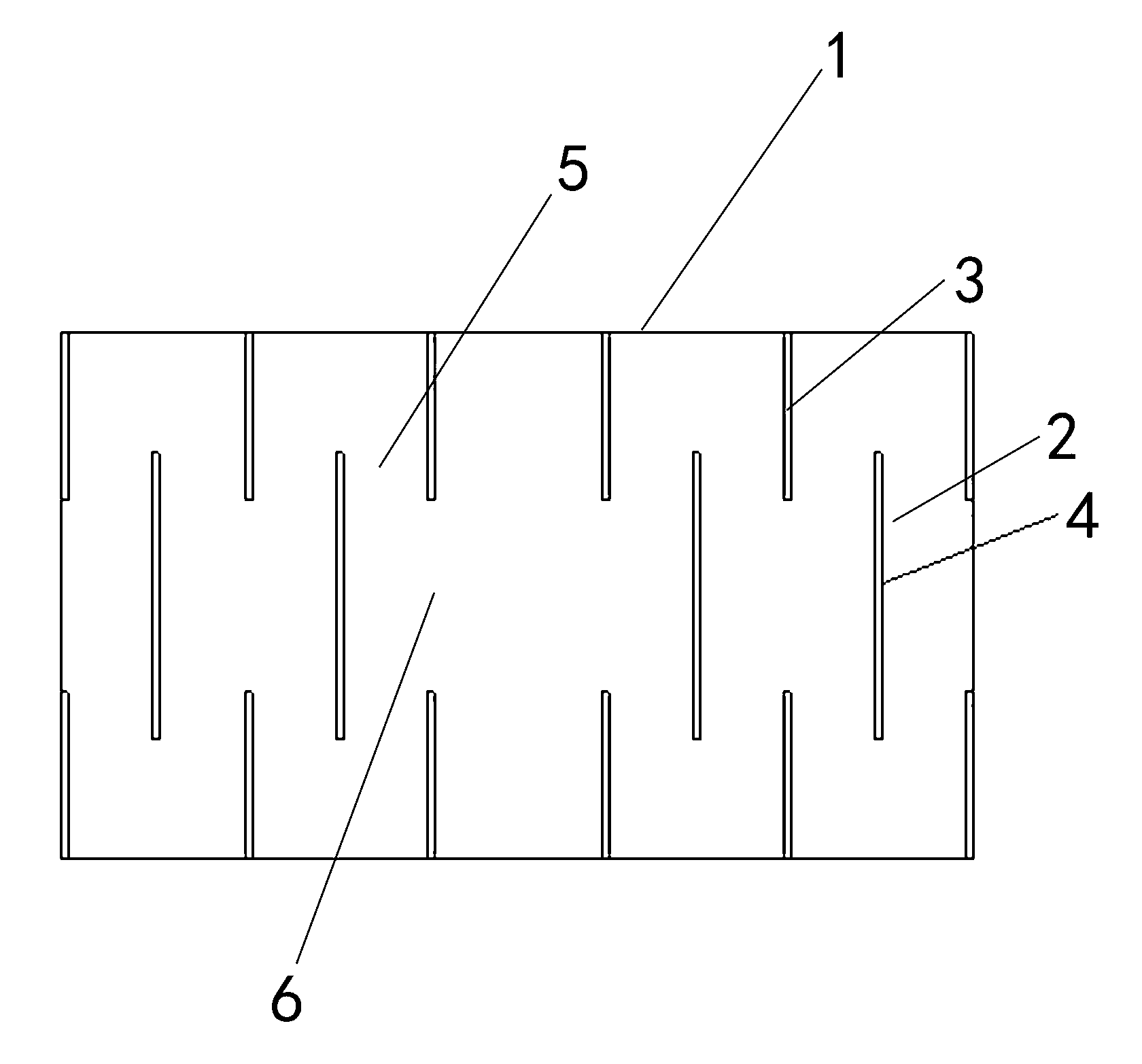

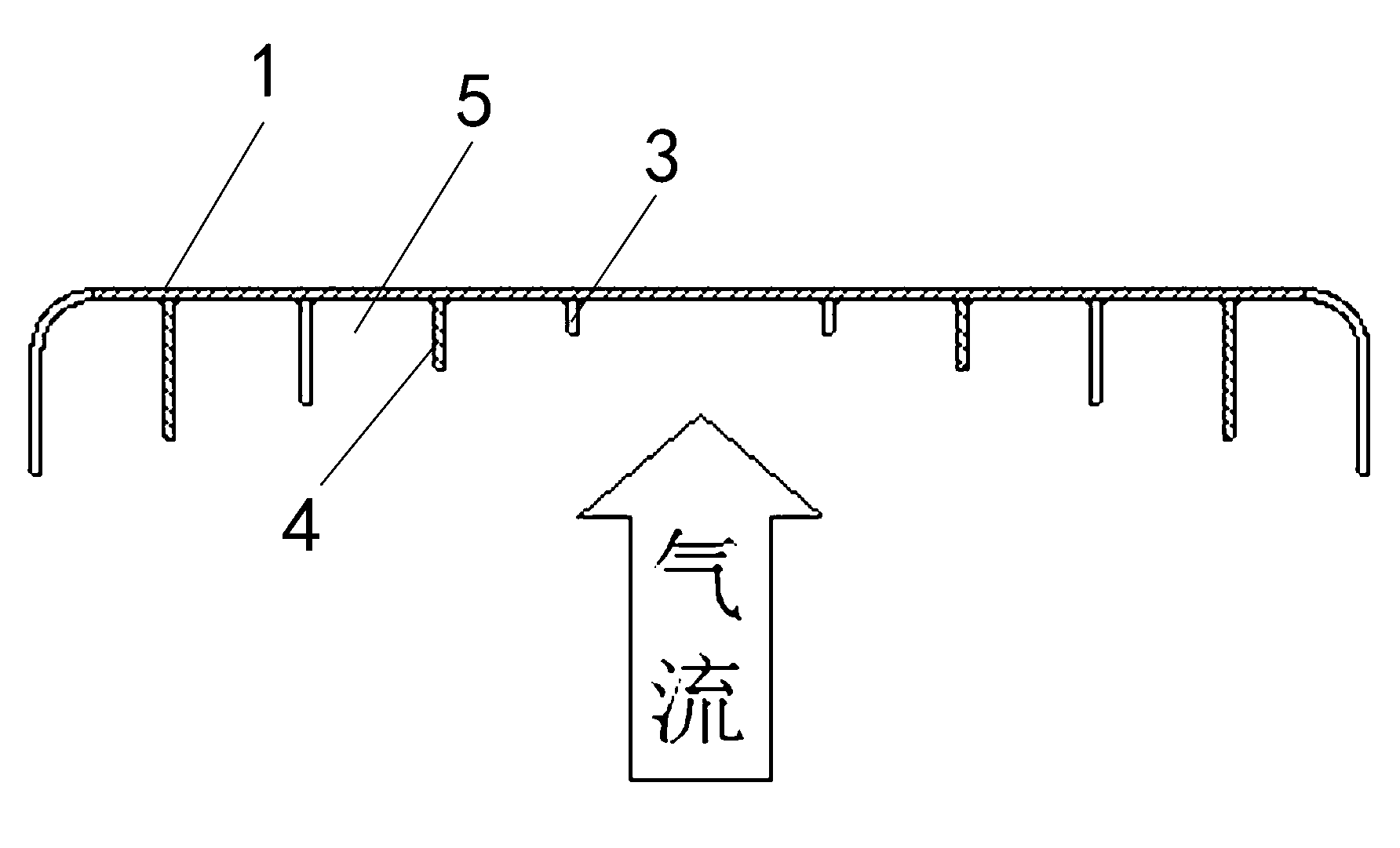

[0010] The invention discloses an oil-gas separation component structure, which includes a component body 1, which is different from the prior art in that several grid plates 2 are distributed on the surface of the component body 1 . The grid plate 2 is arranged perpendicular to the component body 1 .

[0011] In specific implementation, two short grid plates 3 are arranged on the side near the center of the component body 1, the two short grid plates 3 are located in a straight line, and the outer ends of the short grid plates 3 are fixedly connected to the edge wall of the component body 1, The inner ends of the short grids 3 are suspended, a gap 6 is formed between the suspended ends of the two short grids 3, and a long grid 4 is arranged at the component body 1 outside the two short grids 3, and the long grid 4 is connected to the above two A short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com