A combined surface acoustic wave touch screen

A surface acoustic wave and touch screen technology, applied in the field of combined surface acoustic wave touch screens, can solve the problems of surface acoustic wave signal deterioration, reflection stripe array deformation, easy accumulation of dust, etc., to improve safety, reduce the loss of acoustic wave signals, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

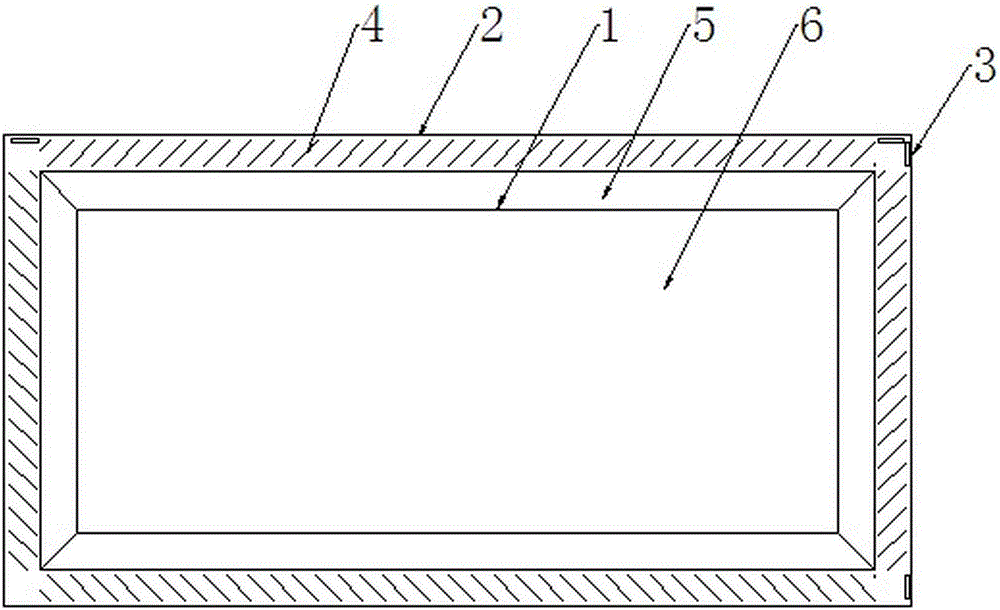

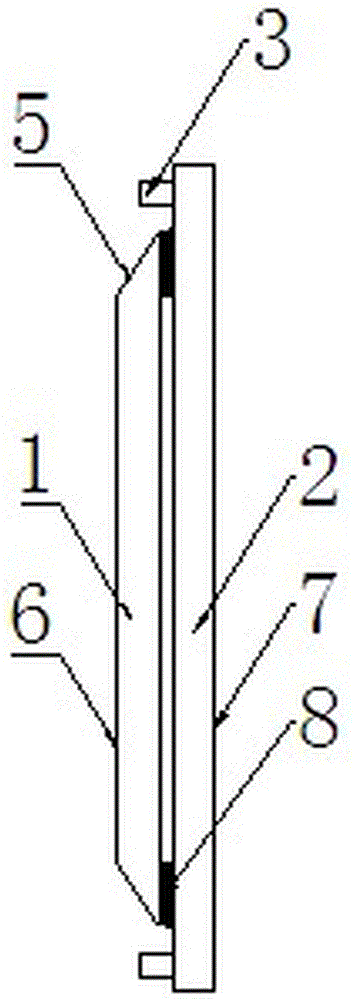

[0045] A combined surface acoustic wave touch screen, including a touch substrate 1, a reflective stripe array 4 and a transducer 3, and also includes an acoustic wave component substrate 2, the reflective stripe array 4 and the transducer 3 are fixedly arranged on the acoustic wave component substrate 2, the acoustic wave component substrate 2 is fixedly connected to the touch substrate 1, and the reflective stripe array 4 and the transducer 3 cooperate on the front surface 6 of the touch substrate 1 to form matrix acoustic signals.

[0046] In this embodiment, the four sides of the touch substrate 1 are preferably set as smooth transition surfaces 5, so that when the surface acoustic wave signal is transmitted between different substrates or between different surfaces of the same substrate, the loss of the acoustic wave signal is smaller .

[0047] Further, when the frame size of the acoustic wave component base material 2 is larger than the frame size of the touch base mate...

Embodiment 2

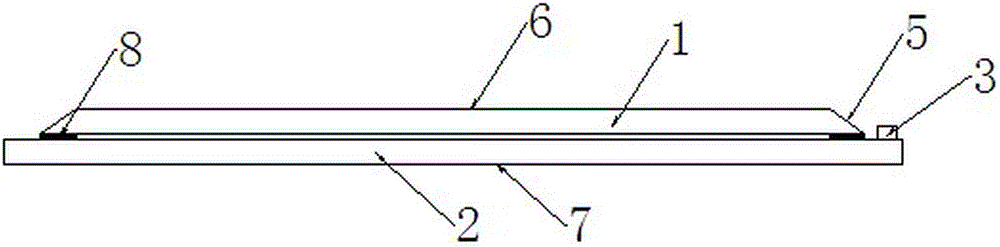

[0049] This embodiment is basically the same as Embodiment 1, the main difference is: when the frame size of the acoustic wave component substrate 2 is larger than the frame size of the touch substrate 1, the four sides of the acoustic wave component substrate 2 are smooth transition surfaces 5 The touch base material 1 is fixedly stacked on the front side 6 of the acoustic wave component base material 2 , and the reflective stripe array 4 and the transducer 3 are fixedly arranged around the back surface 7 of the acoustic wave component base material 2 at this time.

Embodiment 3

[0051] This embodiment is basically the same as Embodiment 1, the main difference is that: when the frame size of the acoustic wave component base material 2 is the same as that of the touch base material 1, the touch base material 1 is fixed on the front side of the acoustic wave component base material 2 6. At this time, the reflective stripe array 4 and the transducer 3 are fixedly arranged around the front 6 or the back 7 of the acoustic wave component substrate 2 .

[0052] Further, the reflective stripe array 4 and the transducer 3 are preferably arranged around the front surface 6 of the acoustic wave component substrate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com