Plasma processing device

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve the problems of intensified plasma bombardment of the focus ring, damage to the focus ring, etc., and achieve the effect of prolonging the service life and uniform treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

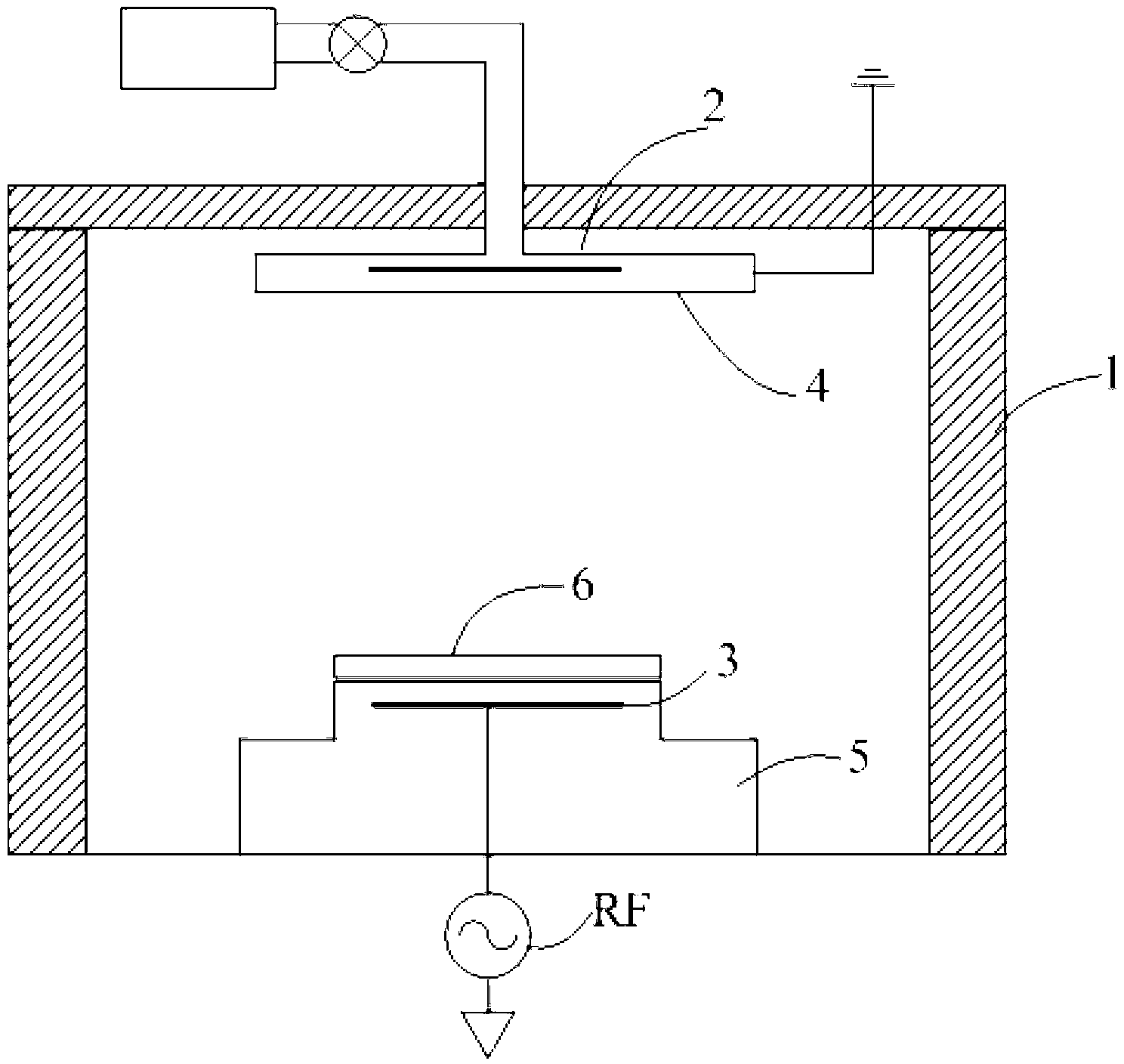

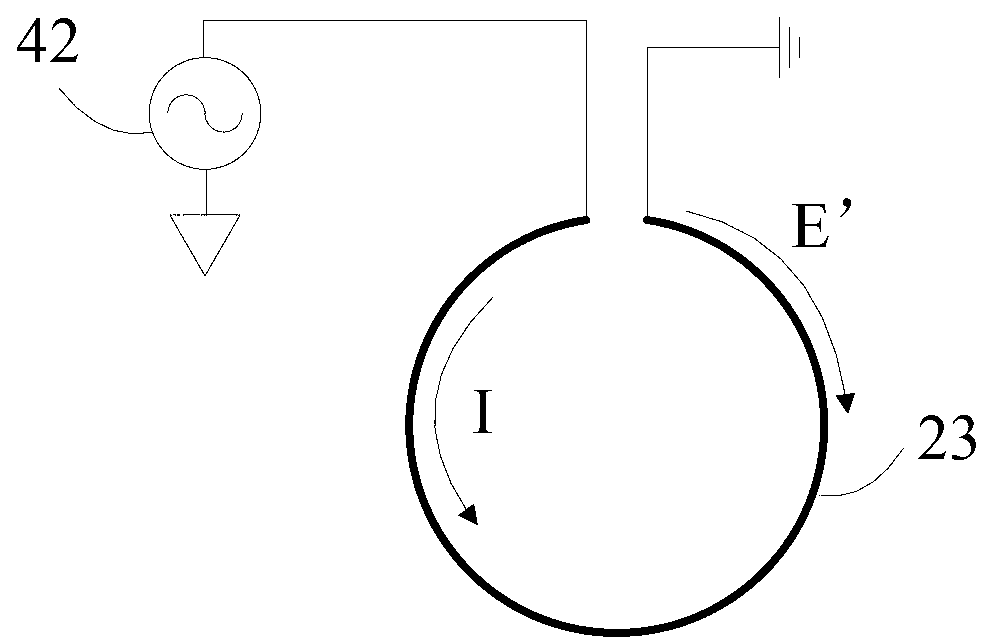

[0031] See figure 2 , which is a schematic structural diagram of the plasma processing chamber in this embodiment. The plasma processing device comprises a reaction chamber 10, wherein a reaction gas is introduced; the top of the reaction chamber 10 is provided with a reaction gas shower head 11, and the reaction gas shower head 11 includes a flat upper electrode 21, and the upper electrode 21 is grounded. ; The bottom of the reaction chamber 10 is provided with an electrostatic chuck 12 for clamping a substrate 30, which can be a semiconductor substrate to be etched or processed or a glass plate to be processed into a flat panel display. A flat-plate lower electrode 22 parallel to the upper electrode 21 is disposed in the electrostatic chuck 12 . The lower electrode 22 is connected to the first radio frequency source 40a and the second radio frequency source 40b through the first radio frequency matching device 41 . The first radio frequency source 40a and the second radio...

Embodiment 2

[0037] Figure 4 is a schematic structural view of another embodiment of the plasma processing device provided by the present invention, Figure 4 The illustrated embodiments can be provided independently or in combination with the above-described embodiments.

[0038] The difference between this embodiment and Embodiment 1 is that the reaction chamber in this embodiment includes a plasma confinement assembly 15, which includes a plurality of concentric rings 15a stacked on each other in the vertical direction and arranged parallel to each other at intervals. These concentric rings 15a Surrounding the area above the electrostatic chuck, that is, the area between the upper electrode 21 and the lower electrode 22 , this area can be considered as a reaction area P where plasma is formed and the substrate 30 is processed. There is a gap between the adjacent concentric rings 15a. When the substrate 30 is treated with plasma, the treated reaction gas can be discharged out of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com