A casing-less switch reluctance traction machine

A technology of switched reluctance and traction machine, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of inconvenient installation and use, high production cost, and large noise pollution, and achieve simple structure, low cost, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The best embodiment of the present invention will be further described in detail below.

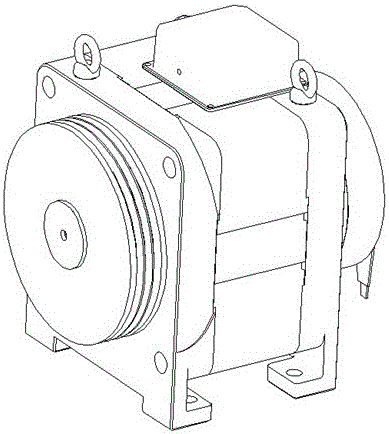

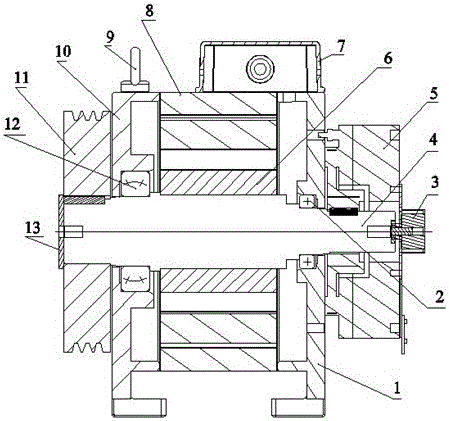

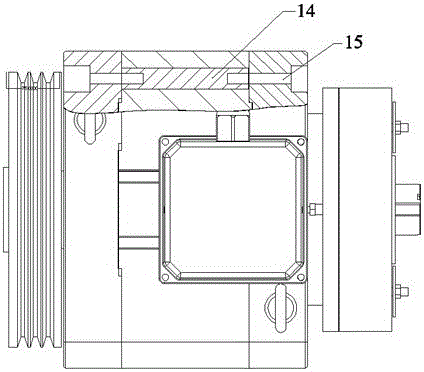

[0031] Such as Figure 1~2 As shown, the switch reluctance traction machine without casing mainly includes an end cover A1, a rotor shaft 4, a rotor core 6, a stator core 8, an end cover B10, and a traction wheel 11. The rotor shaft 4 The middle part is connected to the rotor core 6 through the synchronous shaft of the flat key. One side of the rotor core 6 is provided with an end cover A1 which is axially connected to the rotor shaft 4 through a deep groove ball bearing 2. A brake 5 is provided outside the end cover A1. The brake 5 is locked at the end of the rotor shaft 4 by a flat key, and the outer side of the brake 5 is locked by bolts to the encoder 3, and the encoder 3 rotates synchronously with the rotor shaft 4; The sub-bearing 12 is axially connected to the end cover B10 on the rotor shaft 4, and the outer side of the end cover B10 is provided with a traction sheave 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com