Workpiece turnover device for reshaping and binding of front and rear ends of wound core

A turning device, front and rear end technology, applied in the field of new energy electric vehicle winding iron core shaping and binding workpiece turning device, workpiece turning device, to reduce the number of hoisting and save logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

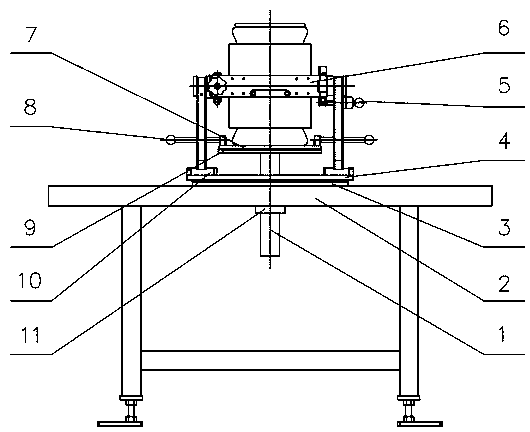

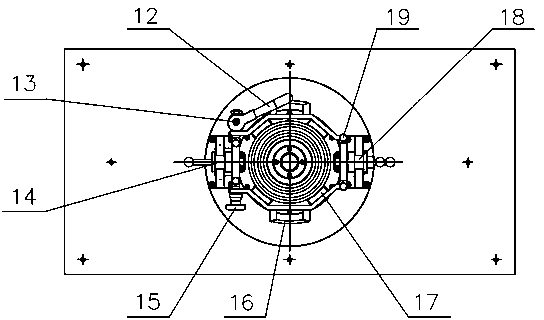

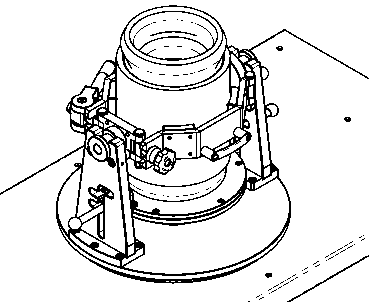

[0030] In order to further understand the reversing device for shaping and bundling workpieces at the front and rear ends of the wound iron core, the technical solutions of the present invention are further described below with reference to the accompanying drawings.

[0031] The front and rear ends of the winding iron core are shaped and bundled with the workpiece turning device, which is characterized in that: it includes a horizontal rotation mechanism, a lifting mechanism, a space turnover mechanism and a clamping mechanism; the horizontal rotation mechanism includes a worktable 2, a bottom plate 3 and a rotary table 4; The bottom plate 3 is fixed on the workbench 2, and the distances between the bottom plate 3 and the two ends of the workbench 2 are equal, the bottom plate 3 is provided with a rotary table 4, the rotary table 4 is centered by the linear bearing 11, and the circumference of the bottom plate 3 is evenly provided with Wear-resistant nylon pad; the lifting mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com