Preparation equipment for large-size fine embossed metal plate

A metal and embossing technology is applied in the field of large-scale fine pattern metal embossed plate preparation equipment, which can solve the problems that the equipment is not easy, easily affected by temperature changes, and the film alignment requirements are too high, and achieve the effect of accurate exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

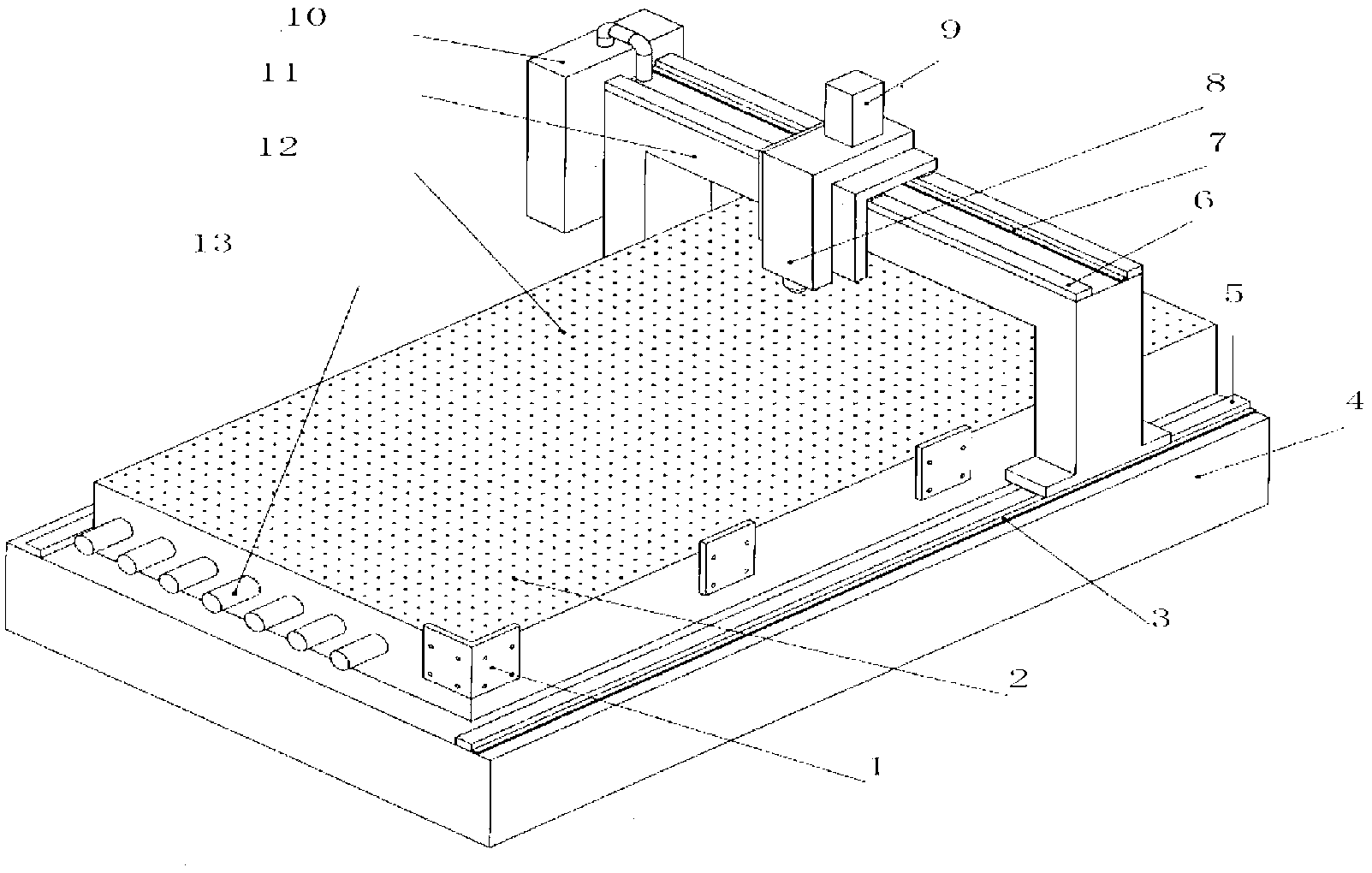

[0023] figure 1 As shown, the large-scale fine pattern metal embossed plate preparation equipment includes a control device 10, a moving beam 11, a vacuum and air flotation platform 12, a sub-regional vacuum blowing catheter 13, uniform air holes 2, a right-angle positioning point 1, and an X-axis grating Ruler 3, frame 4, X-axis motor drive assembly 5, Y-axis motor drive assembly 6, Y-axis grating ruler 7, laser exposure head 8, Z-axis automatic ranging lifter 9; frame 4 is provided with a backing plate and Right-angle positioning point 1, two sides of the plate-shaped machine base 4 prepared by metal plate are equipped with X-axis moving guide rails and at least one side is equipped with X-axis grating ruler 3, and the moving beam is placed on the two sides of X-axis moving guide rails. The axis motor driving assembly 5 drives the moving beam to move on the X axis and is detected and positioned by the X-axis grating ruler 3. The Y-axis moving guide rail, the Y-axis grating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com