Vehicle tire safety device

A safety insurance, tire technology, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve the problems of large tire damage, heavy weight, inconvenient installation and replacement, etc., to reduce the overall weight, enhance rigidity and compression resistance Intensity, the effect of increasing the continuation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

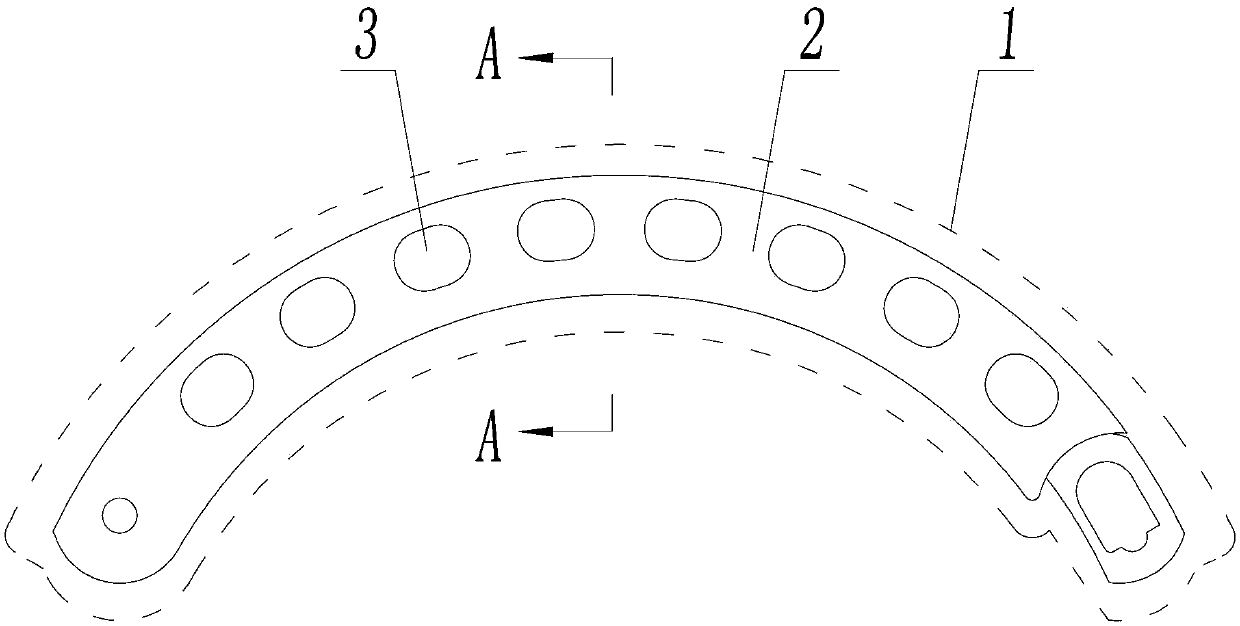

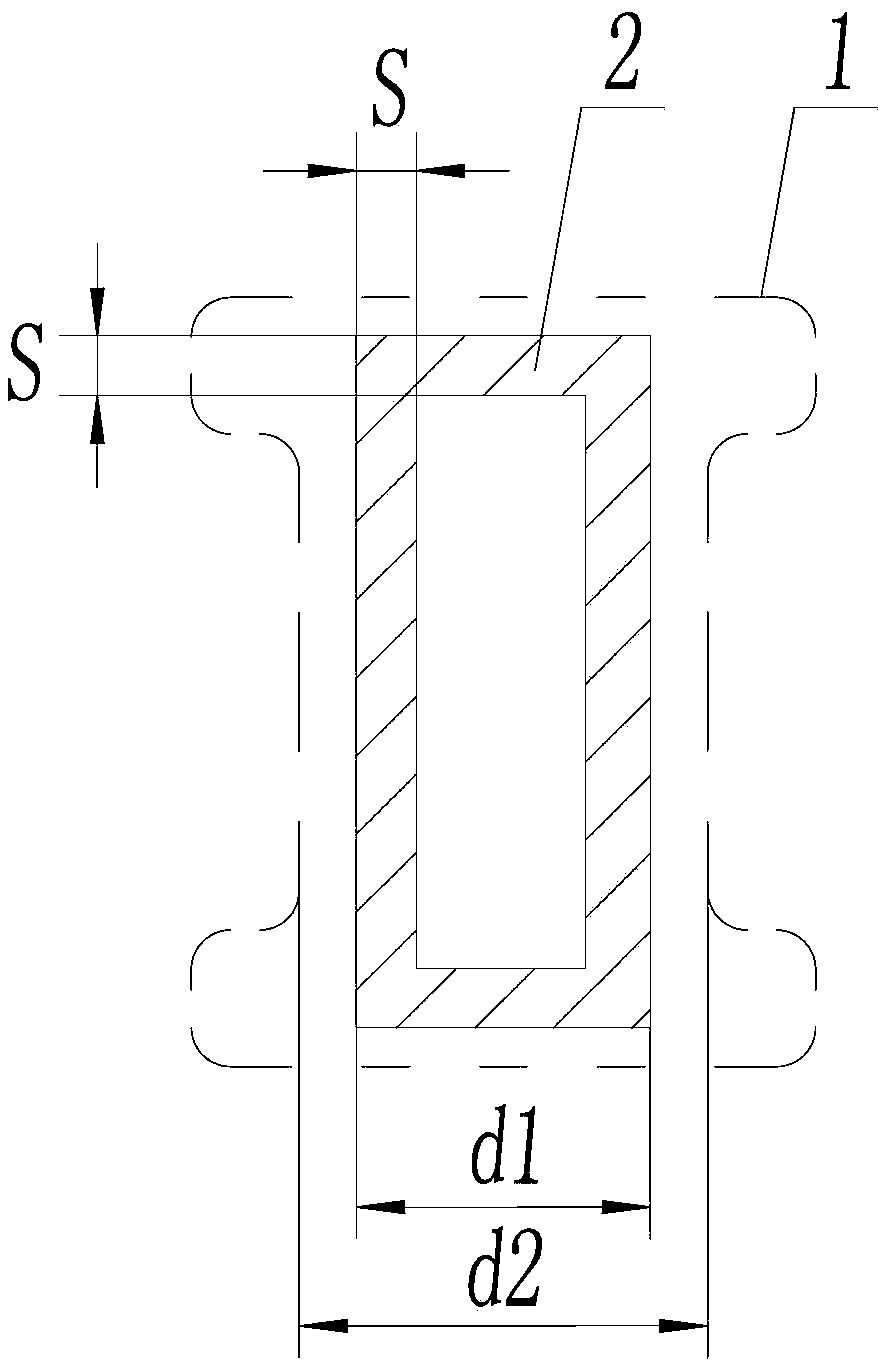

[0022] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. Such as figure 1 As shown, a vehicle tire safety insurance device includes an engineering plastic ring that is arranged inside the tire and surrounds the hub. The engineering plastic ring is formed by connecting two or three arc-shaped bodies 1. A metal structure 2 is arranged inside, and the metal structure 2 is set according to the curved shape and structure of the arc body 1; the metal structure 2 can be made of steel, aluminum, alloy and other plates, profiles or pipes. The metal structure 2 can enhance the internal rigidity of the arc body 1, increase the compressive strength, and ensure that the arc body 1 will not break and disintegrate when the vehicle continues to drive on bad roads or tire blowouts.

[0023] A through hole 3 is set on the metal structure 2, and the shape of the through hole 3 can be regular or irregular in shape according to the structure of the arc body ...

Embodiment 2

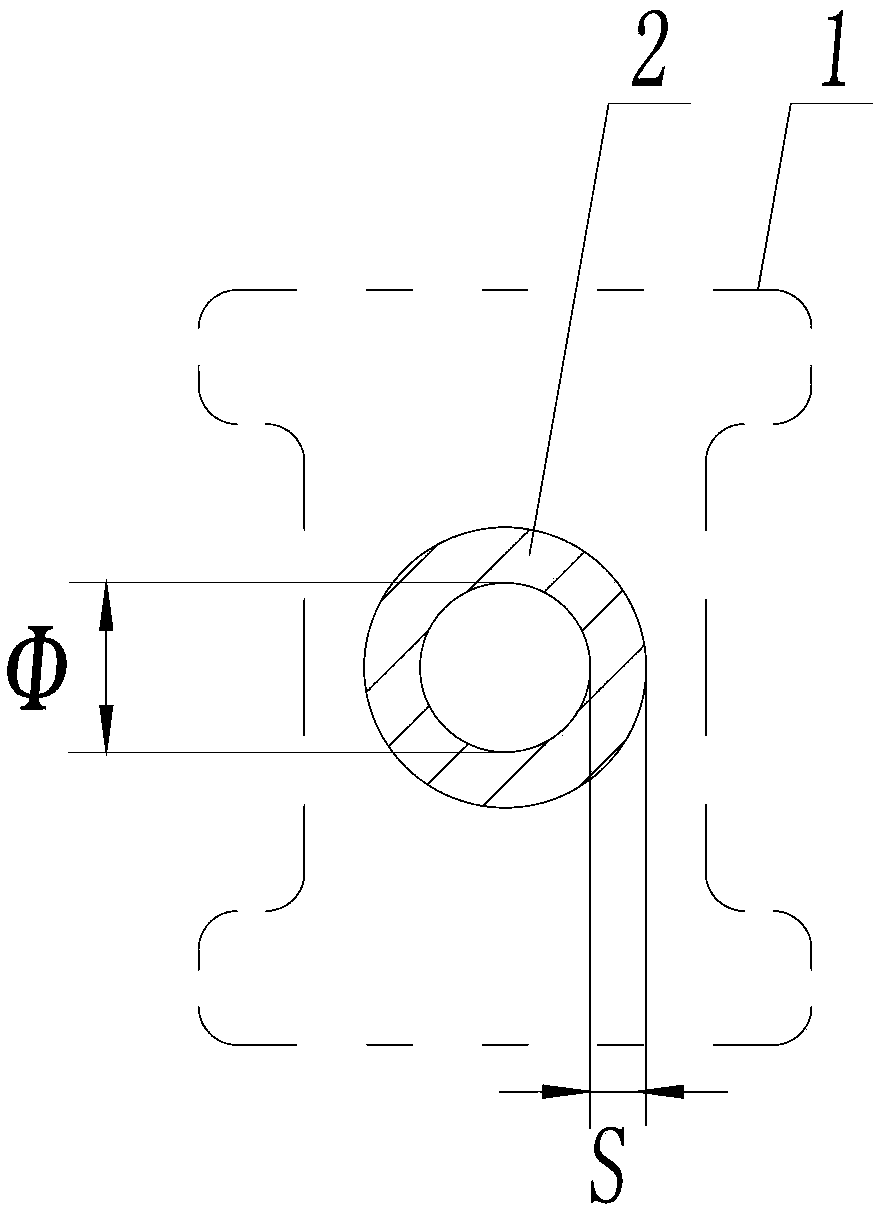

[0027] image 3 It is a sectional view of Embodiment 2 of the present invention. Such as image 3 As shown, the cross-sectional shape of the metal structure 2 is a hollow circular pipe. The inner diameter Φ of the circular pipe is 10-30 mm, and the thickness S of the pipe wall is 2-3 mm. For the arc body 1 provided with a through hole, the circular pipe can be arranged at the lower part or the upper part of the cross section of the arc body 1 . For the arc-shaped body without through holes, the circular pipe can be arranged in the lower part, upper part or middle part of the cross-section of the arc-shaped body 1 . For the arc-shaped body 1 of a heavy vehicle tire, two or more circular pipes can be arranged in the arc-shaped body 1 . In order to enhance the binding force and reduce the weight, a certain number of through holes can be arranged on the surface of the circular pipe.

Embodiment 3

[0029] Figure 4 It is a sectional view of Embodiment 3 of the present invention. Such as Figure 4 As shown, the cross-sectional shape of the metal structure 2 is a hollow triangular pipe. The thickness S of the pipe wall is 3-5 mm. For the arc body 1 provided with through holes, the triangular pipe can be arranged at the lower or upper part of the cross section of the arc body 1 . For the arc body without through holes, the triangular pipe can be arranged at the lower part or the upper part or the middle part of the cross section of the arc body 1 . For the arc-shaped body 1 of a heavy vehicle tire, multiple triangular-shaped pipes can be arranged in the arc-shaped body 1 . In order to enhance the binding force and reduce the weight, a certain number of through holes can also be arranged on the surface of the triangular pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com