Production method of high-strength hot-dip galvanizing steel strip

A technology of hot-dip galvanizing and production methods, which is applied in the direction of hot-dip galvanizing, coating, metal material coating technology, etc., can solve the problems of low strength, slow cooling speed, and difficult cooling speed of galvanized sheets, and achieve the best results Good stability, improved strength, simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

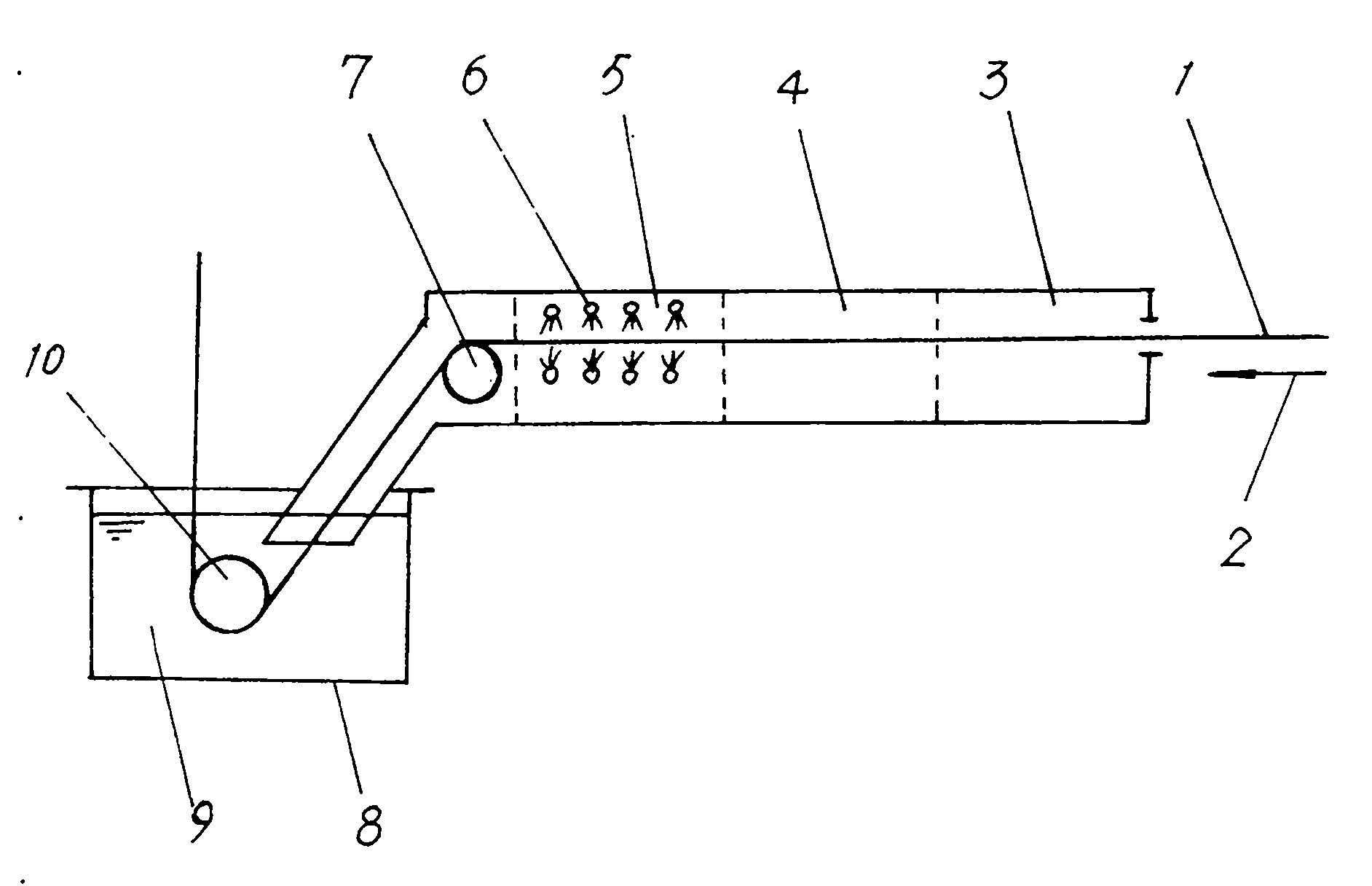

[0011] Please see accompanying drawing, in one embodiment of the present invention, steel strip (1) enters heating furnace along steel strip running direction (2) and carries out annealing treatment, at first in heating furnace heating zone (3), be heated to about 700- 800 ℃, and after being kept at the above temperature for a period of time in the heating furnace holding section (4), it enters the heating furnace cooling section (5), which is the relevant area of the present invention. The present invention adopts that a plurality of spray nozzles (6) and other additional devices are arranged on the upper and lower sides of the steel strip (1) in the cooling section (5) of the heating furnace, so that the steel strip (1) can be sprayed from the upper and lower directions without causing the steel The cooling medium that produces oxidation, the cooling medium selected by the present invention is liquid at the ambient temperature, and will immediately vaporize when sprayed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com