Silicon material melting heating process capable of preventing silicon leakage in quartz crucible in Czochralski method

A quartz crucible and heating process technology, applied in the direction of self-melting liquid pulling method, chemical instruments and methods, crystal growth, etc., can solve the problems of quartz crucible deformation, hanging on the wall, heavy losses, etc., to reduce impact and soften completely. , the effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

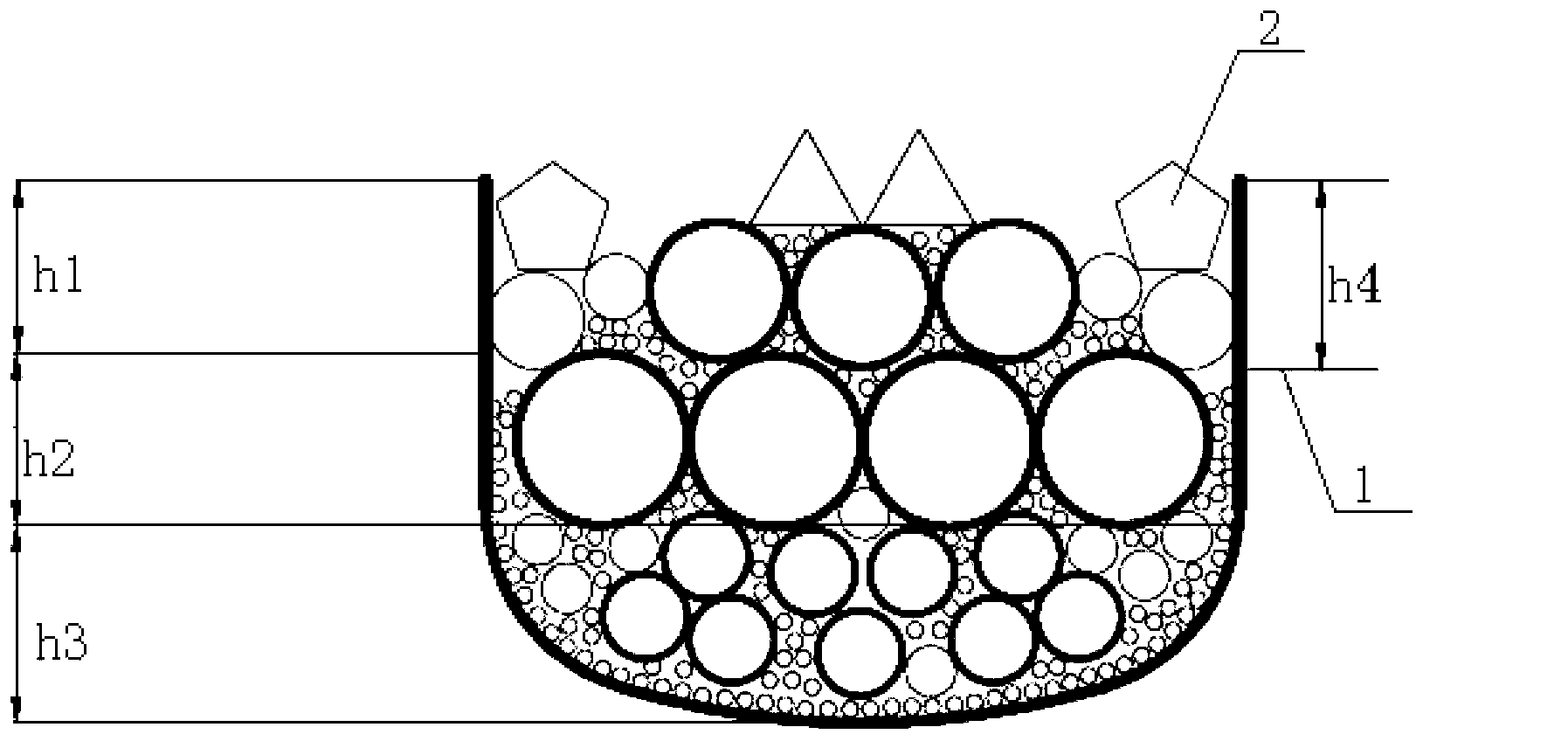

[0030] 18 inch heat system, such as figure 1 Shown: h1, h2, h3 in the figure are the upper, middle, and lower parts of the crucible respectively, h1 is 100mm, h2 is 100mm, and h3 is 114mm. h4 is the height between the edge of the quartz crucible and the 60kg liquid level, and h4 is 110mm.

[0031] 1) Loading (the lower part is for small materials, the middle is for small and large materials, and the upper part is for small and medium materials):

[0032] 1.1) When charging, ensure that the silicon material below the liquid level line of the quartz crucible should be packed as densely as possible, and it is better to adopt surface contact between the middle and lower parts and the crucible wall. The block material above the liquid level line should preferably have a point contact surface, so as to avoid deformation of the quartz crucible caused by bending the quartz crucible inward due to hanging edges in the molten material.

[0033] 1.2) The upper layer of edge material (th...

Embodiment 2

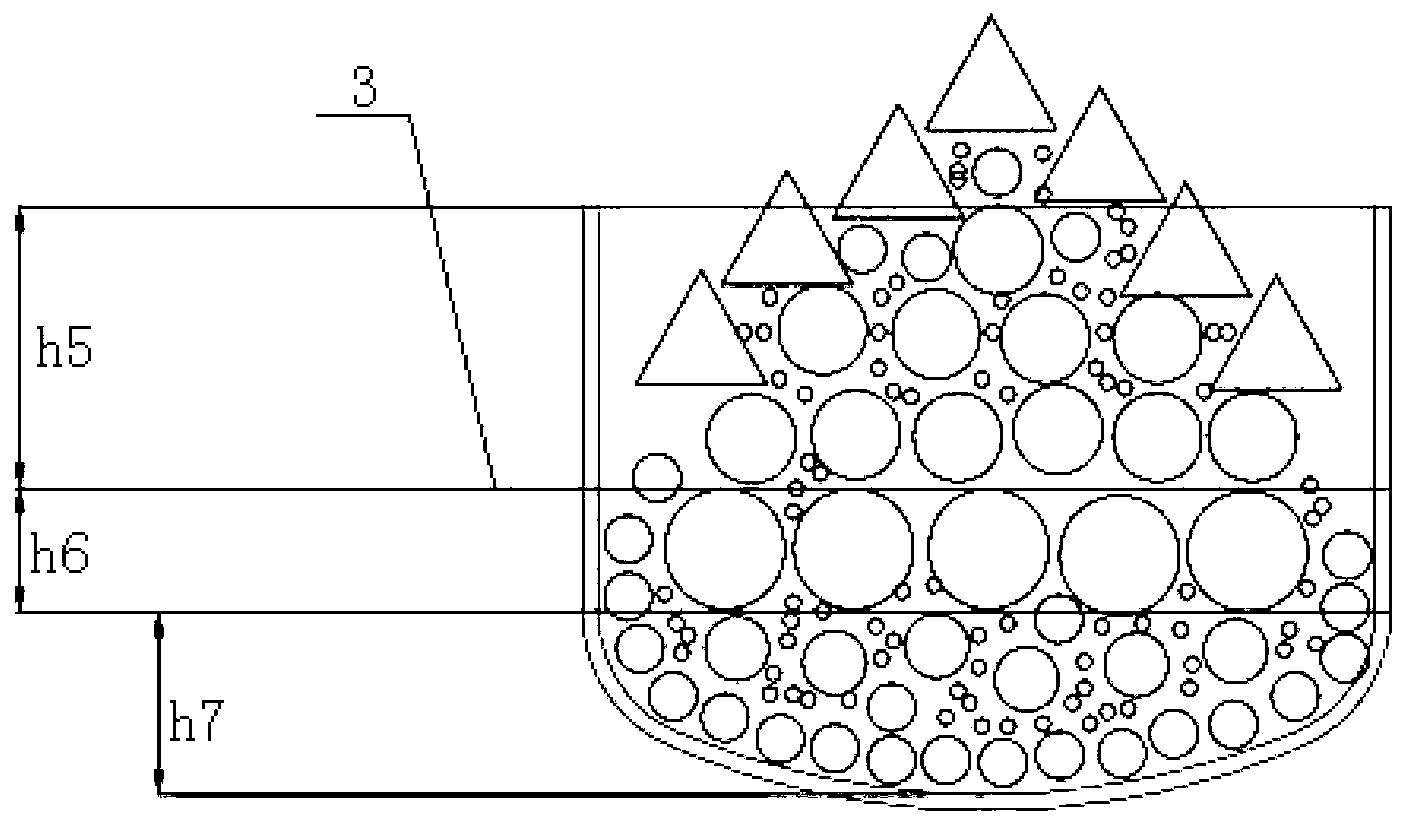

[0043] 20 inch heating system: such as figure 2 Shown: h5, h6, and h7 in the figure are the upper, middle, and lower parts of the crucible respectively, h5 is 175mm, h6 is 76.87mm, and h7 is 113.13mm.

[0044] 1) Loading (the lower part is for small materials, the middle is for small and large materials, and the upper part is for small and medium materials):

[0045] 1.1) When charging, ensure that the silicon material below the liquid level line of the quartz crucible should be packed as densely as possible, and it is better to adopt surface contact between the middle and lower parts and the crucible wall. The block material above the liquid level line should preferably have a point contact surface, so as to avoid deformation of the quartz crucible caused by bending the quartz crucible inward due to hanging edges in the molten material.

[0046] 1.2) The upper layer of edge material (the edge material is the raw material that is placed on the edge of the crucible at the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com