Collagen fiber regenerated leather and manufacturing method thereof

A technology for collagen fibers and regenerated leather, which is applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as high production costs, and achieve the effects of reducing production equipment costs, reducing production costs, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

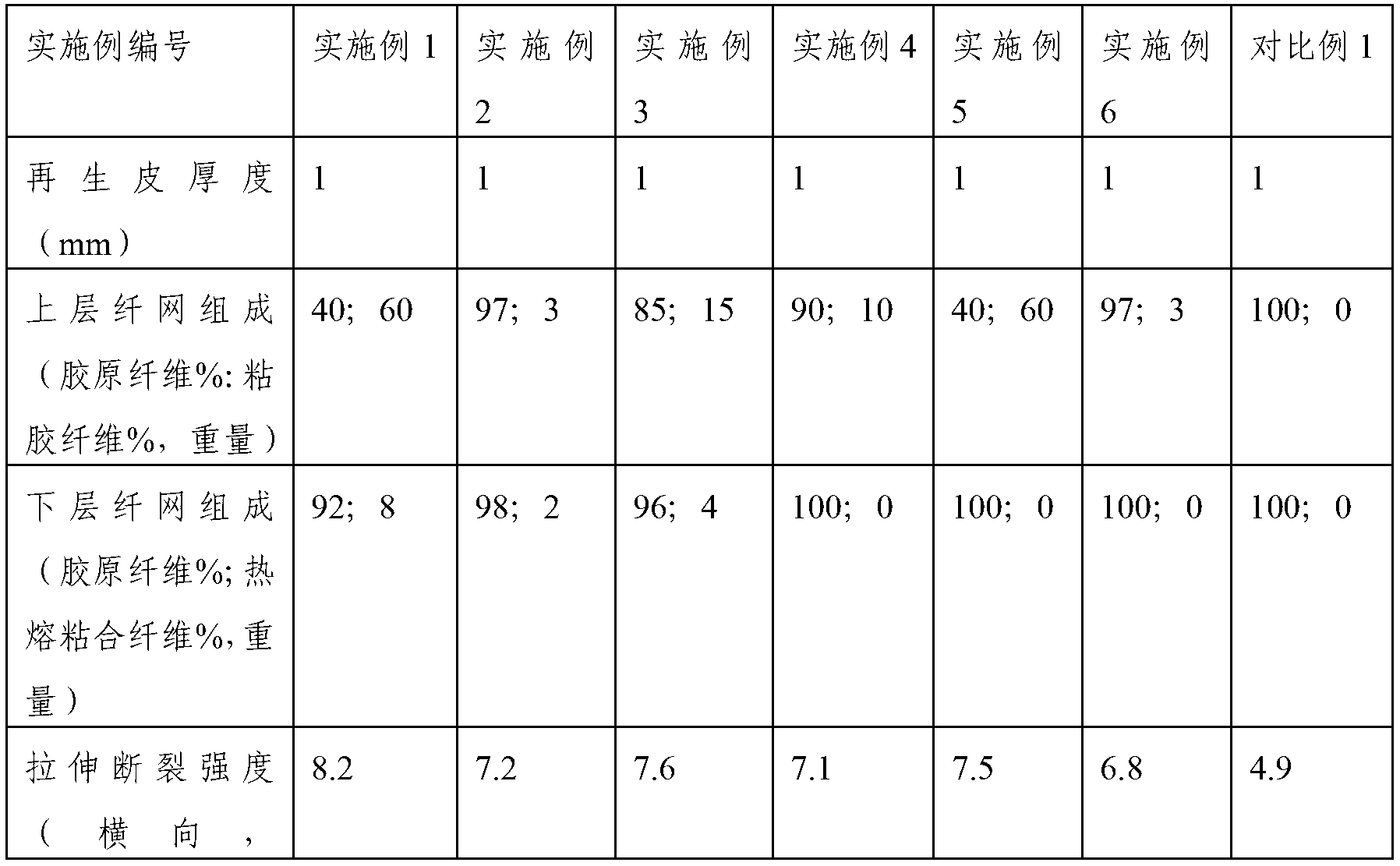

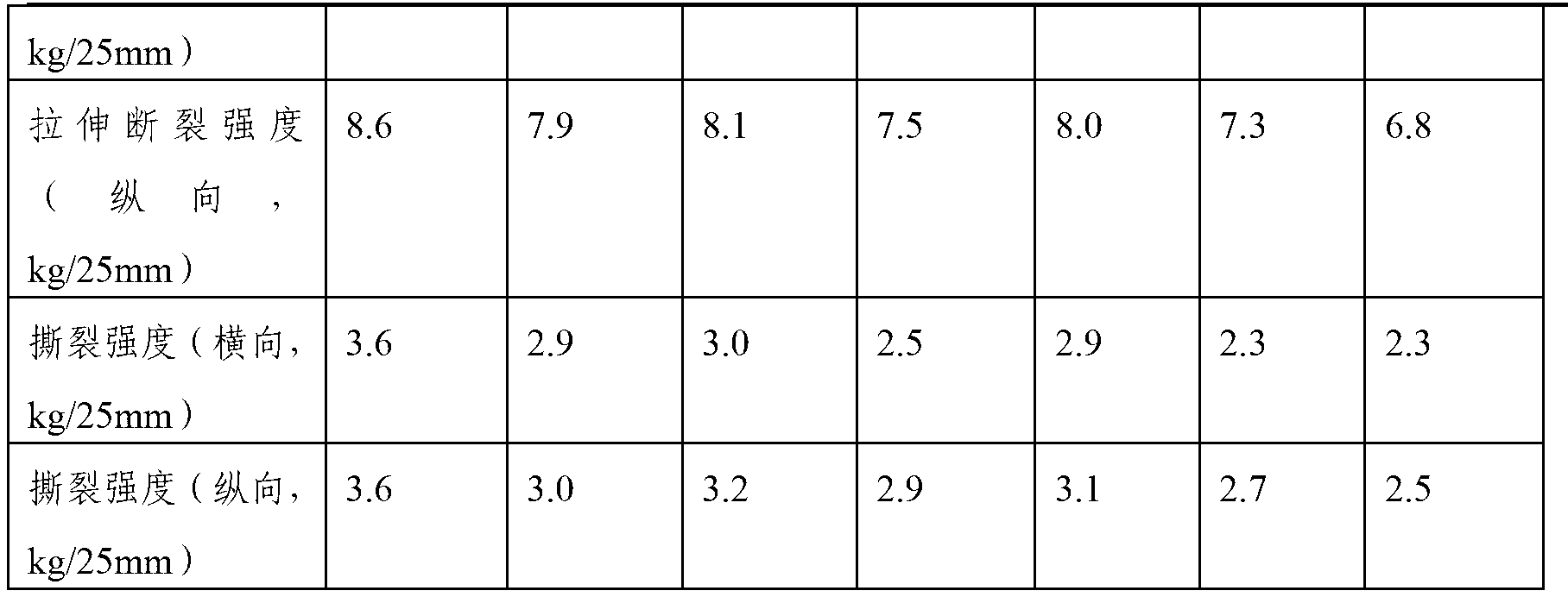

[0043] The invention relates to a collagen fiber regenerated leather, which is composed of an upper layer fiber web and a lower layer fiber web tightly connected to the lower surface of the upper layer fiber web, wherein, the material composition and weight percentage of the upper layer fiber web are: collagen fiber 40%, viscose 60% glue fiber; the material composition and weight percentage of the lower fiber web are: 92% collagen fiber, 8% hot-melt adhesive fiber; the length of the collagen fiber is 1-3cm. The thickness of the regenerated leather is 0.5-3 mm, the transverse and longitudinal tear strengths are both above 23N, and the transverse and longitudinal tensile strengths are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0044] The present invention also relates to a method for manufacturing the above-mentioned collagen fiber regenerated leather, which comprises the f...

Embodiment 2

[0052] The invention relates to a collagen fiber regenerated leather, which is composed of an upper layer fiber web and a lower layer fiber web tightly connected to the lower surface of the upper layer fiber web, wherein, the material composition and weight percentage of the upper layer fiber web are: collagen fiber 97%, viscose Glue fiber 3%; the material composition and weight percentage of the lower fiber web are: 98% collagen fiber, 2% hot-melt adhesive fiber; the length of the collagen fiber is more than 1cm, preferably 1-3cm in length. The thickness of the regenerated leather is 0.5-3 mm, the transverse and longitudinal tear strengths are both above 23N, and the transverse and longitudinal tensile strengths are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0053] The present invention also relates to a method for manufacturing the above-mentioned collagen fiber regener...

Embodiment 3

[0061] The invention relates to a collagen fiber regenerated leather, which is composed of an upper layer fiber web and a lower layer fiber web tightly connected to the lower surface of the upper layer fiber web, wherein, the material composition and weight percentage of the upper layer fiber web are: collagen fiber 85%, viscose Glue fiber 15%; the material composition and weight percentage of the lower fiber web are: 96% collagen fiber, 4% hot-melt adhesive fiber; the length of the collagen fiber is more than 1cm, preferably 1-3cm in length. The thickness of the regenerated leather is 0.5-3 mm, the transverse and longitudinal tear strengths are both above 23N, and the transverse and longitudinal tensile strengths are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0062] The present invention also relates to a method for manufacturing the above-mentioned collagen fiber regene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com