Linking member of assembled rooms and sheds

A technology for assembling houses and components, applied in the direction of building structure, construction, etc., can solve the problems of heavy workload, complicated installation process, and inability to customize, and achieve the effects of high component strength, simple structure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

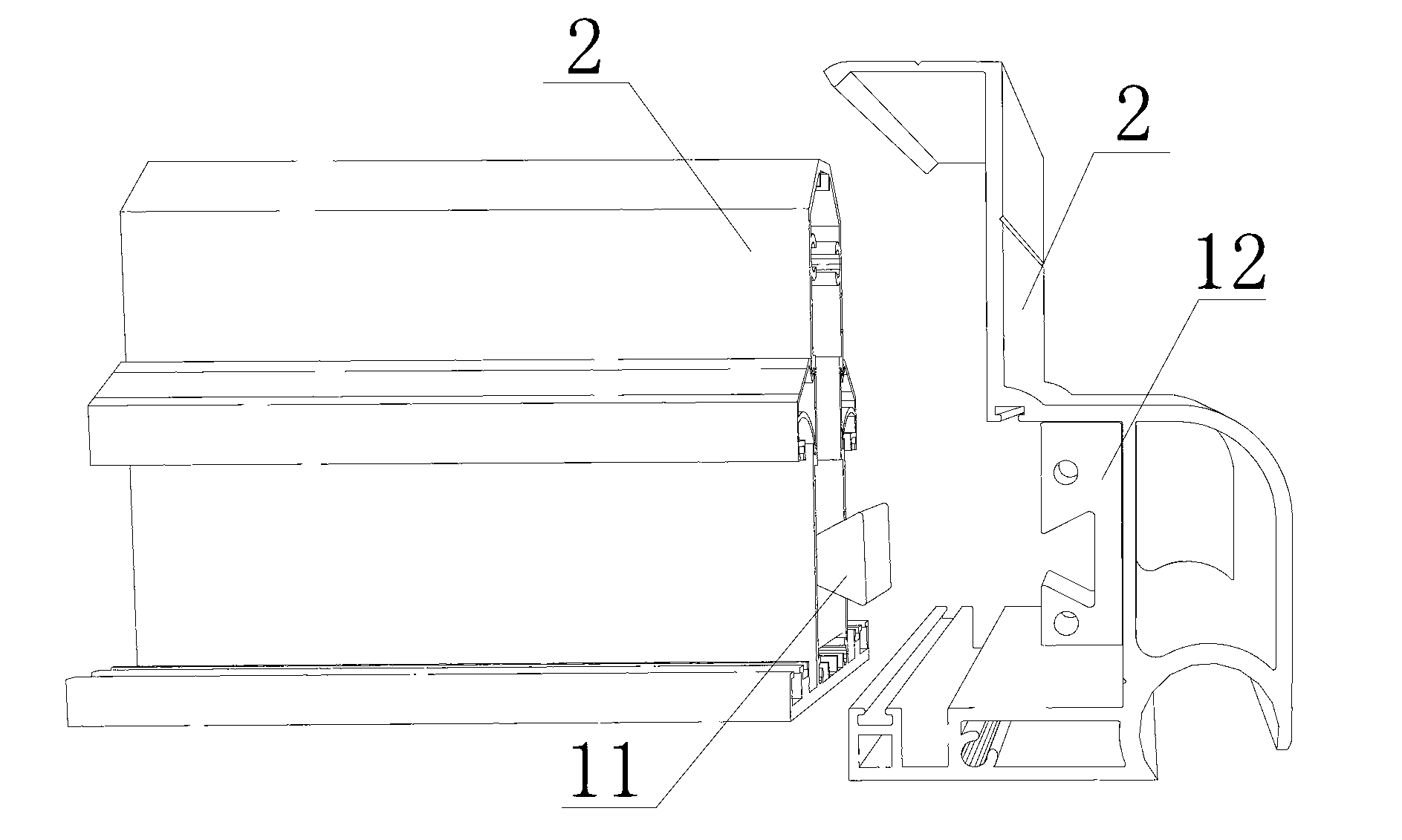

[0023] Such as figure 1 As shown, the present invention is a link member for assembling houses, sheds, etc., and the link member 1 is arranged between joints of interconnected profiles 2 .

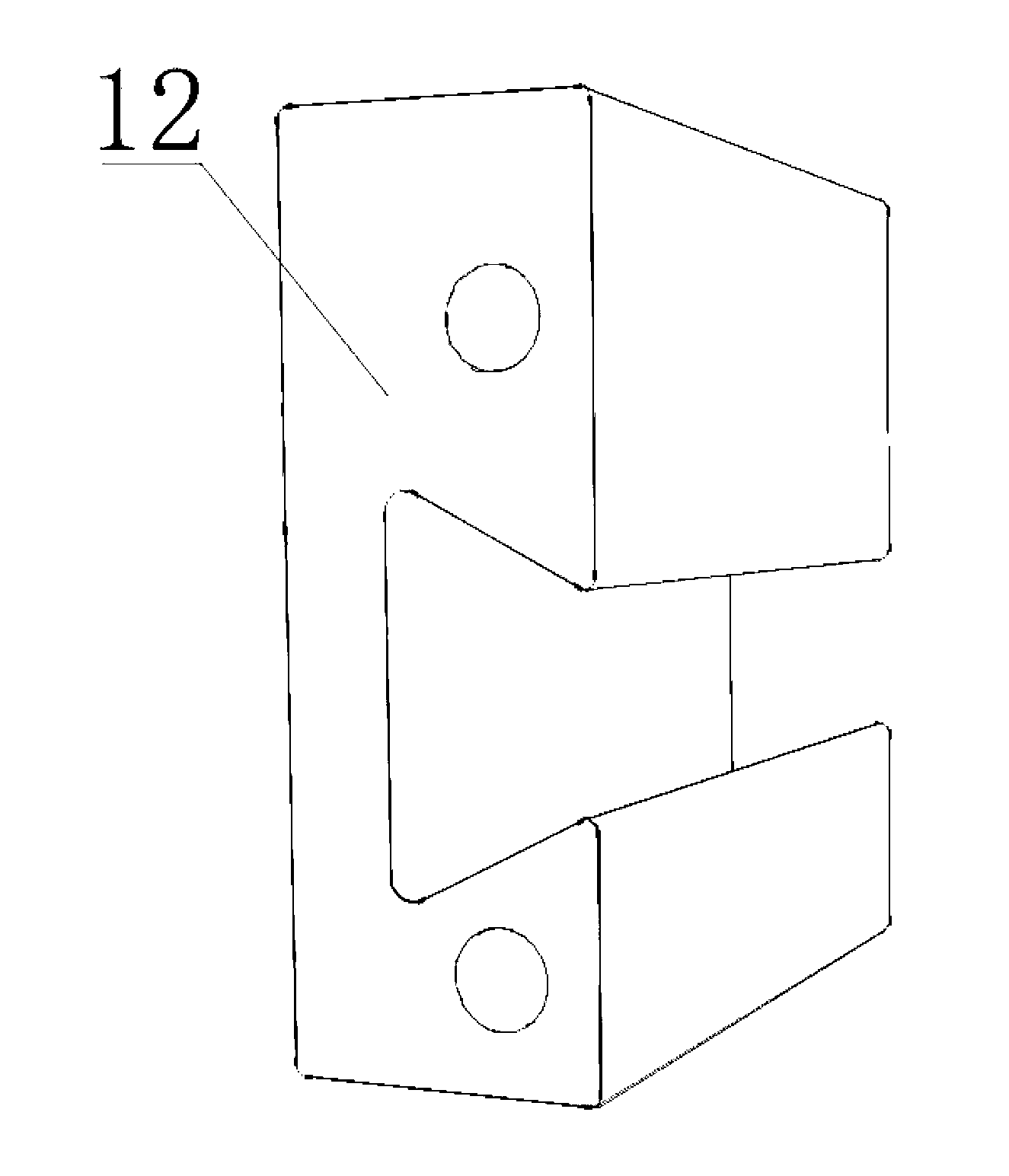

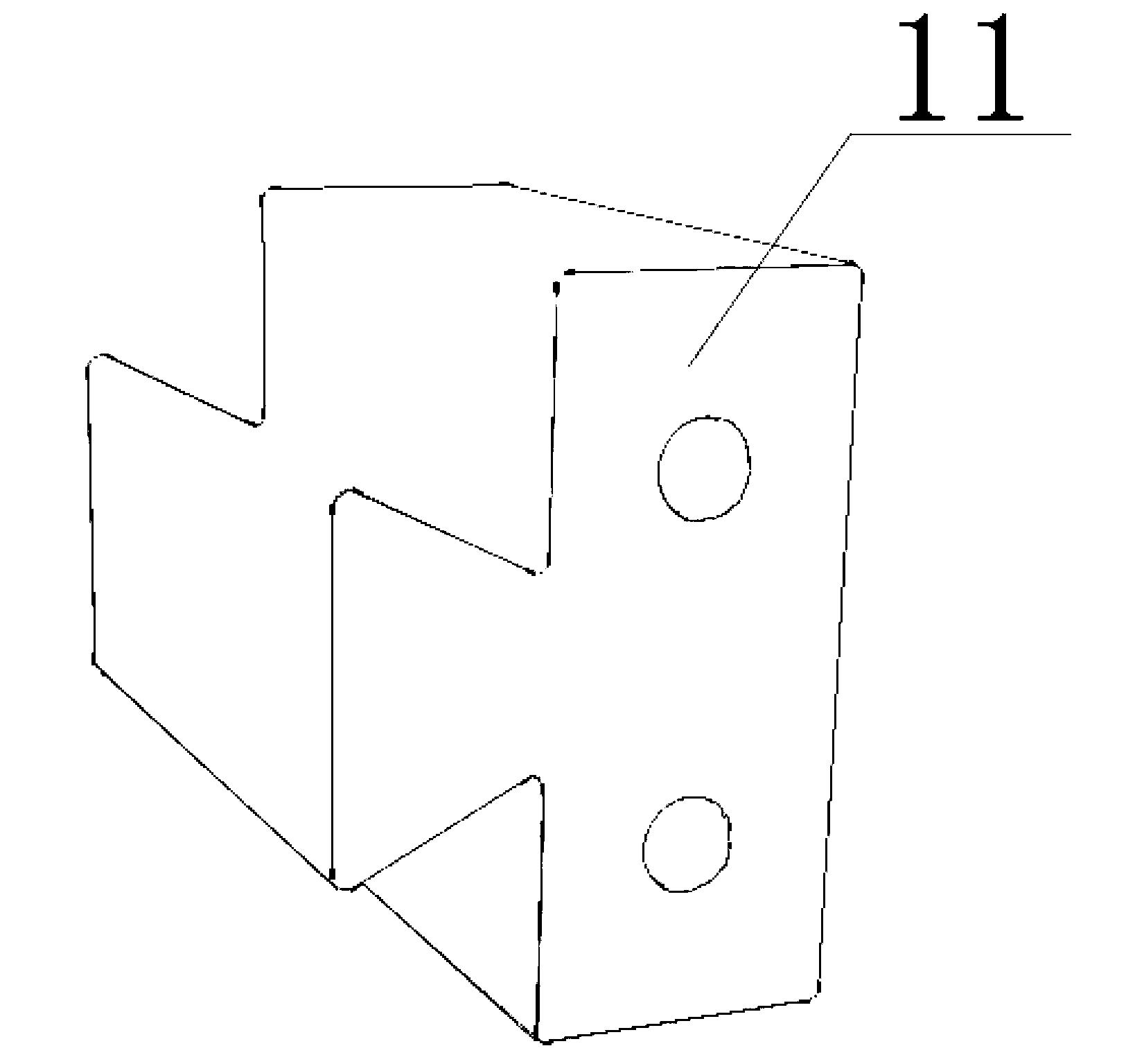

[0024] Such as figure 2 , image 3 As shown, the link member 1 includes a link groove 12, and an embedding portion 11 matching the link groove 12, and the link groove 12 and the embedding portion 11 are respectively fixedly connected to the interconnected profiles 2 on.

[0025] In order to further fix the assembled link member 1 , the link member 1 is further provided with a locating piece, and the locating piece is composed of a locating hole and a screw or a bolt matched with the locating hole.

[0026] It should be noted that the cross section of the linking member can be trapezoidal or semicircular or square or rhombus or any geometric shape in the prior art.

[0027] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com