Floor with multifunctional grooves in upper surface

A multi-functional, floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of inconvenient assembly, single function, poor anti-skid effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

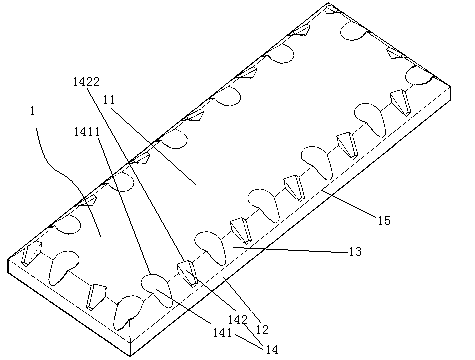

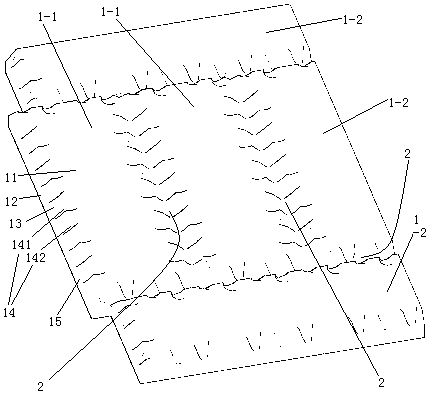

[0028] Embodiment one, see figure 1 , a floor with multifunctional grooves on the upper surface, including a middle base plate 1 . A chamfered surface 13 is provided between the upper surface 11 of the substrate and the side surface 12 of the substrate. The chamfered surface 13 is provided with several pits 14 distributed along the length direction of the chamfered surface. The recess 14 extends to the upper surface 11 of the substrate. The lower edge of the recess 14 is located above the boundary line 15 between the chamfered surface and the side surface of the substrate. The dimples 14 include several first dimples 141 and several second dimples 142 . The edge line 1411 at the opening end of the first pit is formed by connecting arc segments sequentially from end to end. The edge line 1421 at the opening end of the second pit is surrounded by straight line segments connected first and last. The opening area of the first pit 141 is larger than the opening area of the...

Embodiment 2

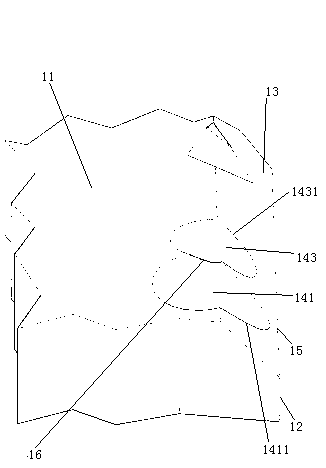

[0030] Embodiment two, see image 3 , the difference from the first embodiment is that a third pit 143 is provided beside the first pit 142 . The shape of the opening of the third pit 143 is the same as that of the first pit. The opening area of the third pit 143 is smaller than the opening area of the first pit 141 . The edge line 1411 of the opening end of the first pit and the edge line 1431 of the opening end of the third pit overlap together. The extrusion opening 16 is formed between the pits where the edge lines of the opening ends overlap.

Embodiment 3

[0031] Embodiment three, see Figure 4 , the difference from the first embodiment is that all the pits 14 have the same opening shape and opening area. The wall 144 of the pit is provided with a plurality of grooves 3 distributed along the circumference of the pit and extending along the depth direction of the pit. The trench 3 extends to the upper surface 11 of the substrate. The width of the upper end of the groove 3 is large, and the width of the lower end is small. Adjacent grooves meet together to form a meeting line 145 . The junction line 145 extends to the upper surface 11 of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com