Oil film thickness measuring device

A measuring device and technology of oil film thickness, applied in the field of lubricating oil, can solve the problems of limited steady-state research, prone to errors, and the simulation conclusion is not completely convincing, and achieves the effect of facilitating the analysis of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

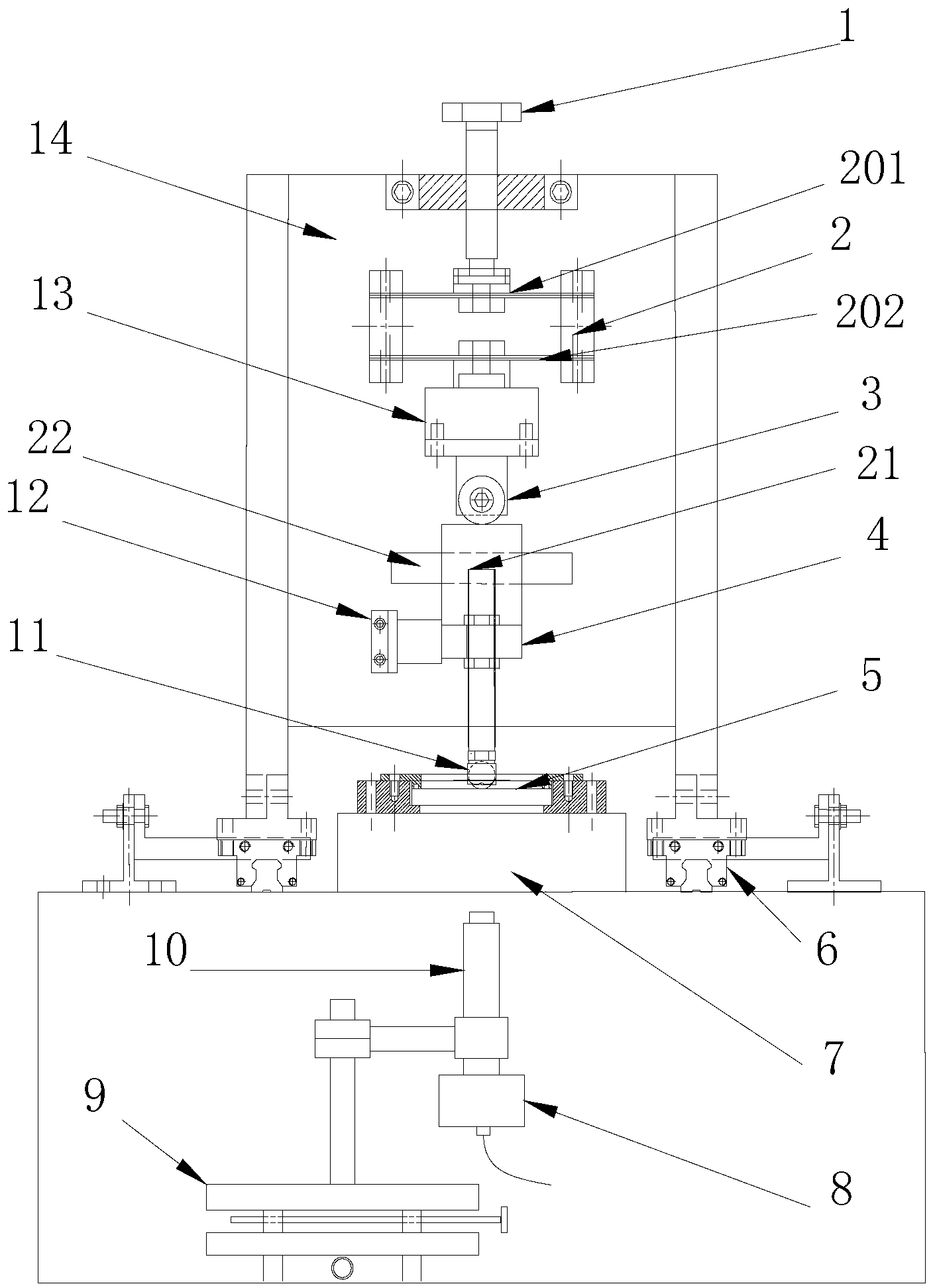

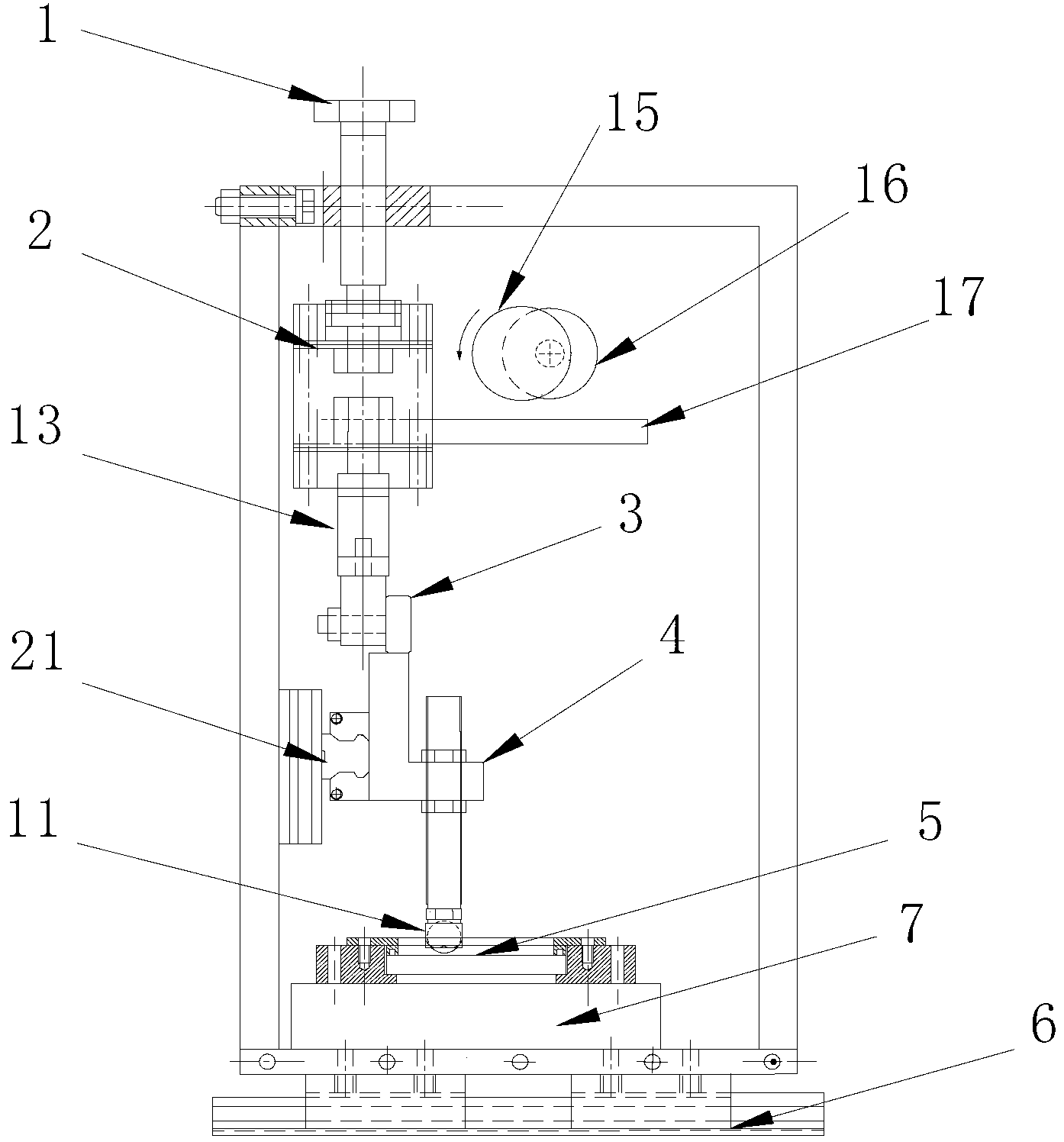

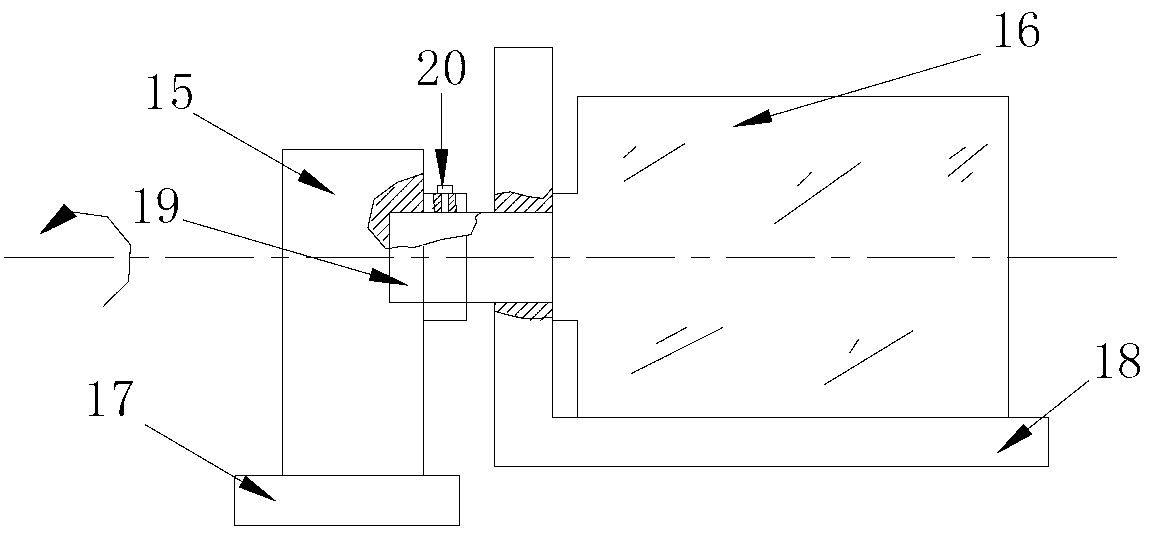

[0033] figure 1 It shows a front view of an oil film thickness measuring device (not including the unsteady load part), which is divided into upper and lower parts, the upper part is the load loading mechanism, and the lower part is the load measuring mechanism. This embodiment selects the eccentric wheel 15 as the loading wheel.

[0034] The left and right ends below the frame I of the load loading mechanism are fixed on the horizontal linear guide rail 6, and the horizontal linear guide rail 6 is fixed on the frame II of the load measuring mechanism. In this way, the position of the load loading mechanism is adjusted by sliding the slider of the horizontal linear guide rail 6, thereby changing the contact radius between the steel ball 11 and the glass disc 5.

[0035] The loading handle 1 is fixedly connected to the back cover 14 of the frame 1 by threads, and is fixed on the frame 1 top, and the lower end of the loading handle 1 is connected with the leaf spring module 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com