Test stand capable of adjusting installation errors for comprehensive performance of spiral bevel gears

A technology of spiral bevel gear and comprehensive performance, which is applied in the field of spiral bevel gear comprehensive performance test bench, can solve the problems of no way to objectively evaluate the quality of bevel gears, high price, and the performance of the inspection machine is difficult to meet the requirements, and achieves compact structure and function. Comprehensive, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

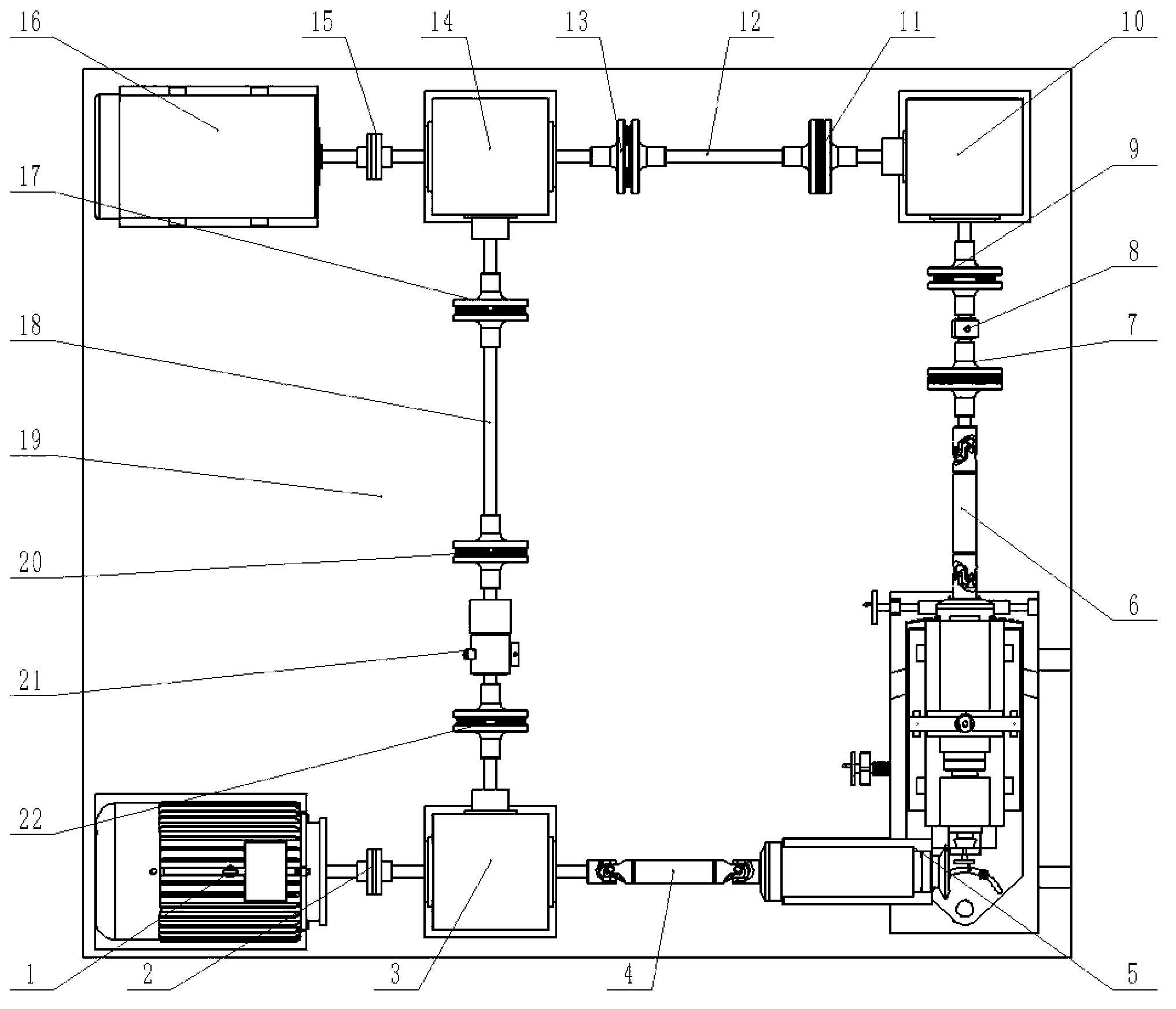

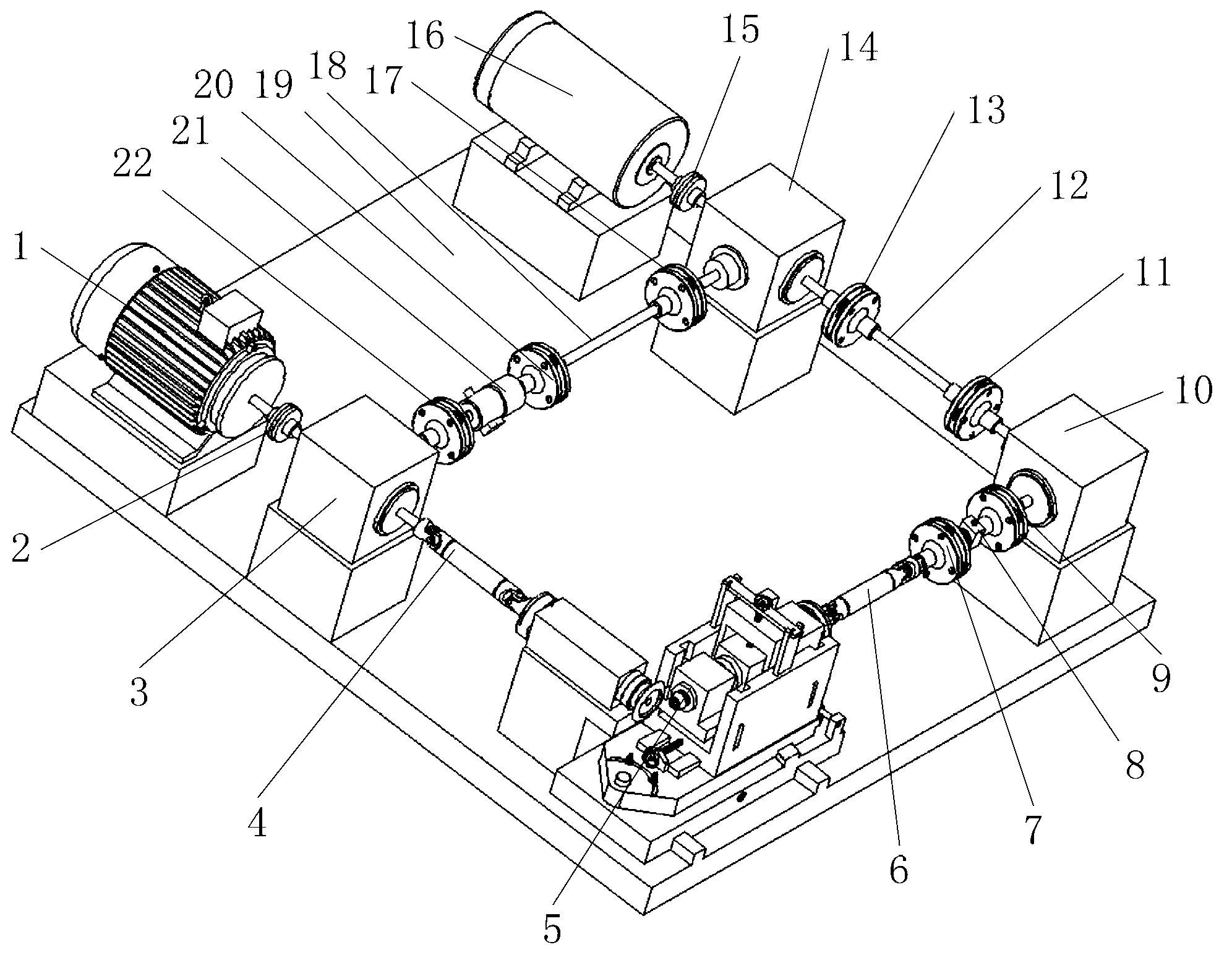

[0027] Such as figure 1 , figure 2 As shown, the present invention includes a variable frequency AC motor 1, a DC motor 16, two 1:1 spiral bevel gearboxes 3,14, a torque sensor 8, a hydraulic loader 21, two circular gratings 23,39, and a test gear shaft system 5. Accompanying test gearbox 10, two clutches 2, 15, seven elastic couplings 7, 9, 11, 13, 17, 20, 22, two universal couplings 4, 6, base 19 and two Root shaft 12, 18.

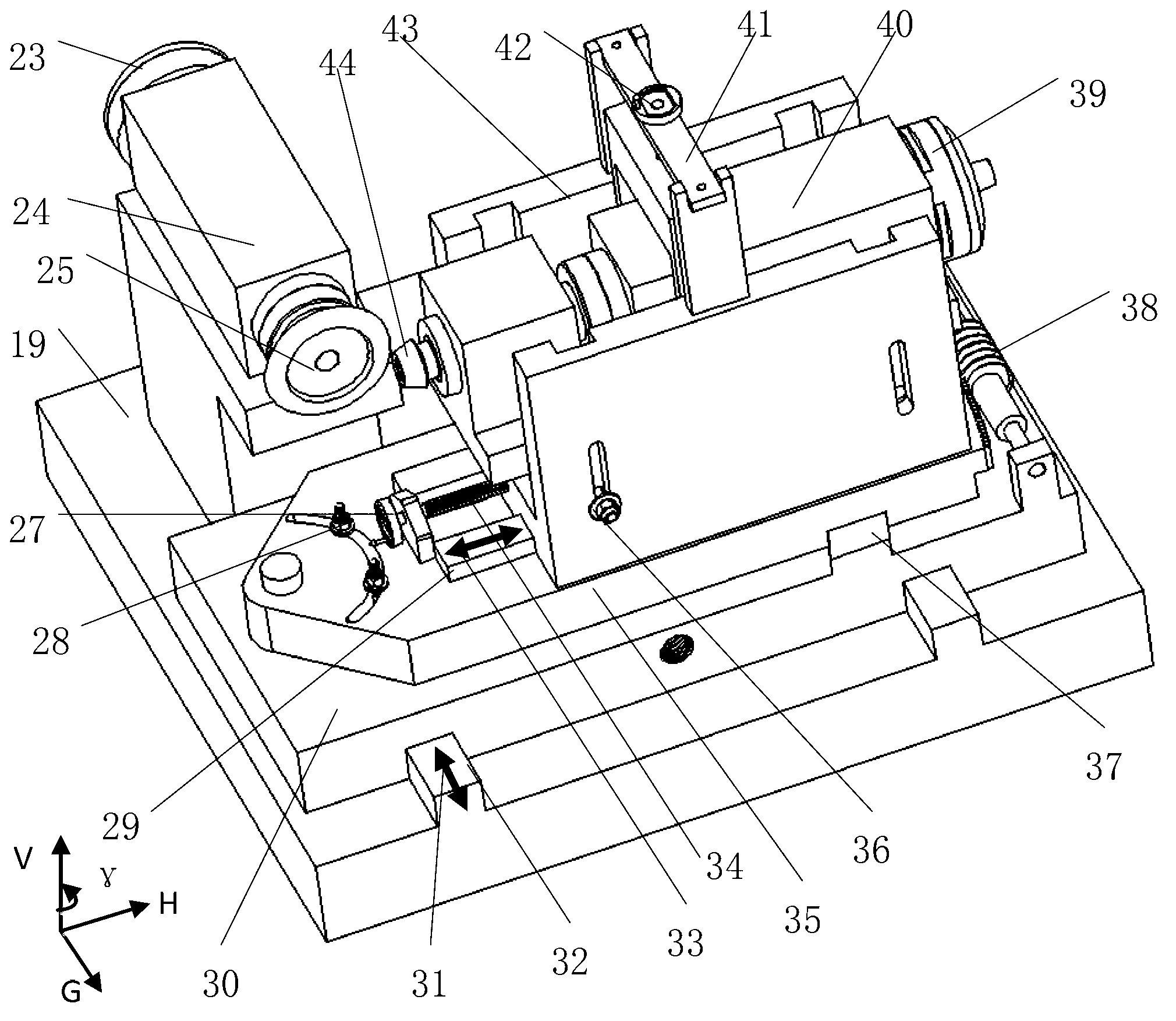

[0028] Such as figure 2 As shown, a variable frequency AC motor 1 is installed on one side of the base 19, and starting from the first variable frequency AC motor 1, the first 1:1 spiral bevel gearbox 3 and the test gear shaft system 5 are sequentially installed counterclockwise. The large axle box 24, the test gear shaft system 5 installed on the two slide rails of the base 19, the gamma direction slide rail and the G direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com