High-throughput large-aperture high-precision lens four-dimensional on-line focus controlling device

A large-diameter, high-precision technology, applied in installation, optics, instruments, etc., can solve the problem of lack of three-dimensional precision adjustment of the lens adjustment mechanism, and achieve the effect of compact structure, fast replacement, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

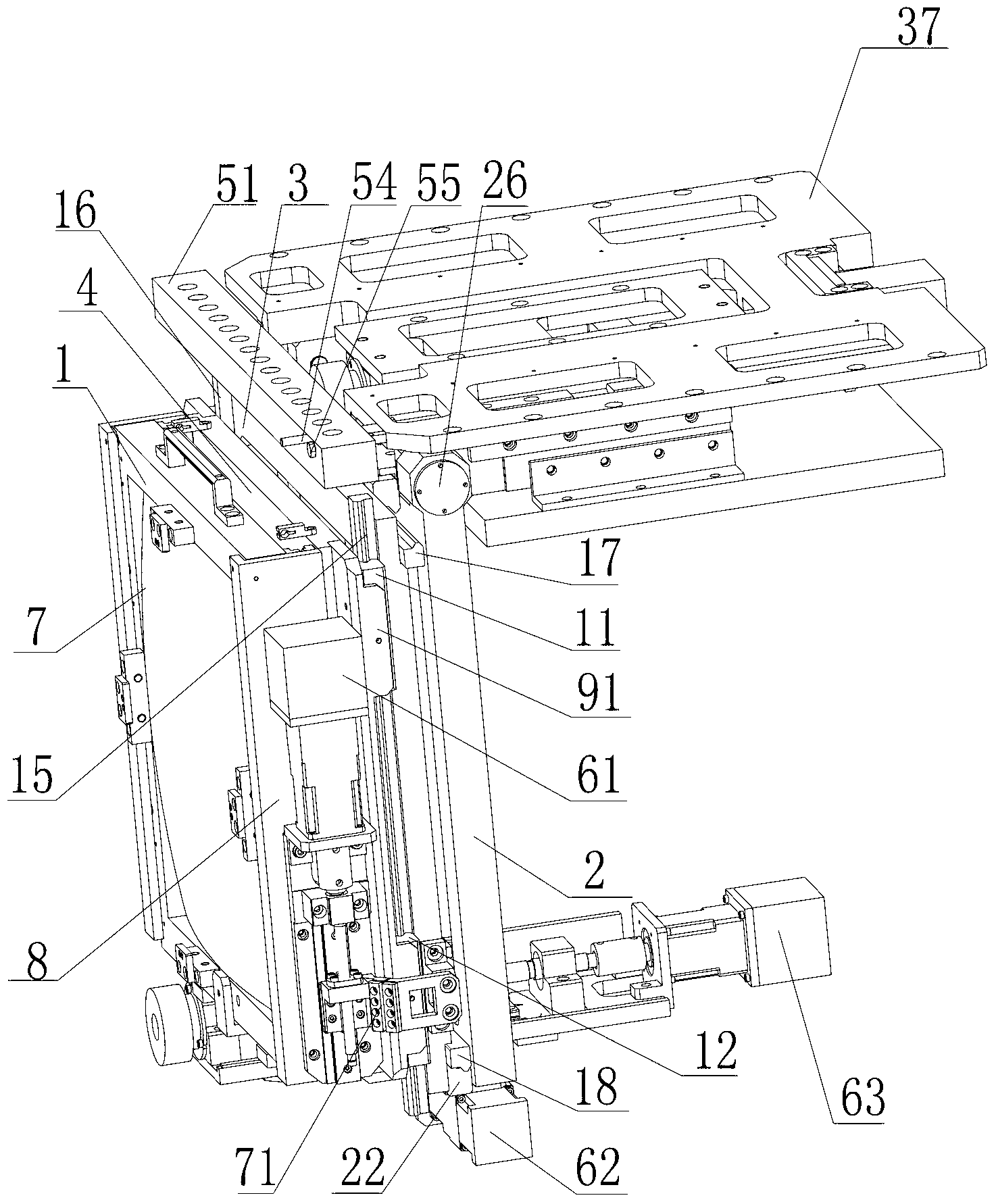

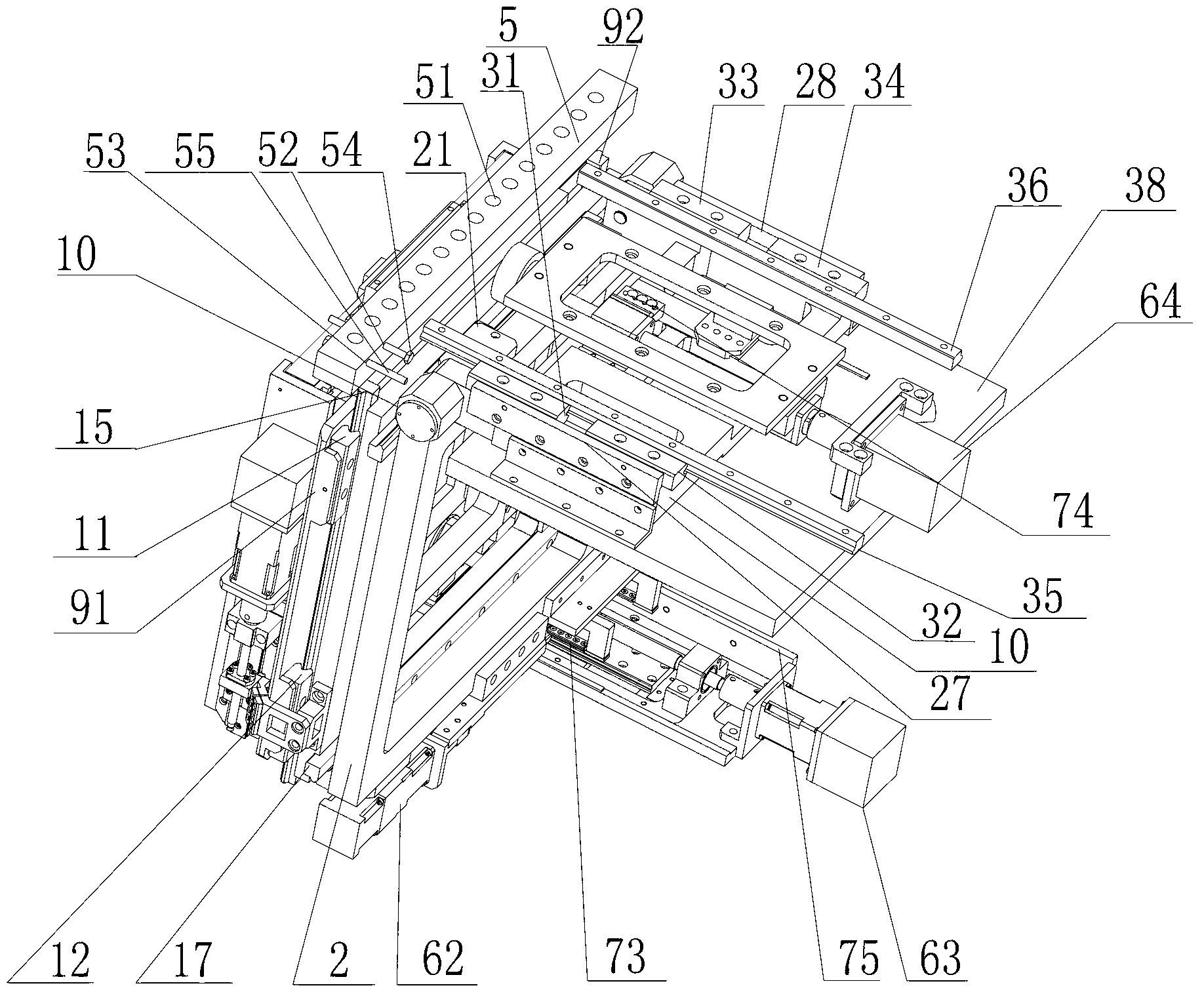

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the device of this embodiment comprises lens frame 1, pitch frame 2, horizontal frame 3, lift frame 4, support frame 5, lens 7, lens frame slideway 8, lift slide block left fixed seat 91, lift slide Block right fixed seat 92, slide plate 10, the first left lifting slider 11, the second left lifting slider 12, the first right lifting slider 13, the second right lifting slider 14, the first guide rail 15, the second guide rail 16. The third guide rail 17, the fourth guide rail 18, the third left horizontal slider 21, the fourth left horizontal slider 22, the third right horizontal slider, the fourth right horizontal slider, the first shaft 25, the second shaft 26. The left fixed seat of the sliding board slider 27, the right fixed seat of the sliding board slider 28, the first left sliding board slider 31, the second left sliding board slider 32, the first right sliding board slider 33,...

specific Embodiment approach 2

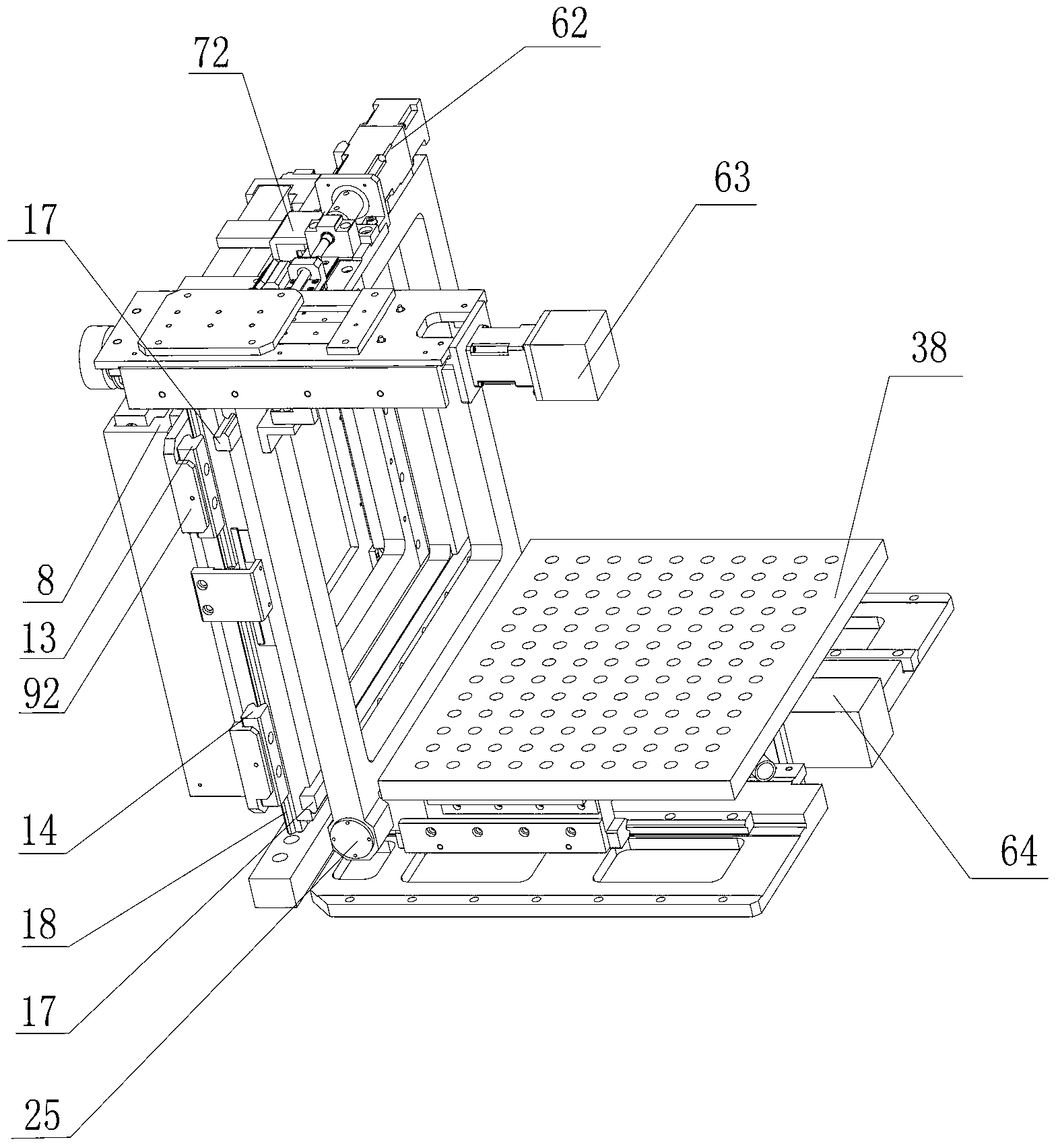

[0008] Specific implementation mode two: combination image 3 Illustrate the present embodiment, the slide plate of present embodiment is equipped with flushing plate 38 below, and the upper end surface of flushing plate 38 is provided with air-filling hole, and the lower end face of flushing plate 38 has array type air outlet, and flushing plate 38 can connect into the clean air to purify the air environment inside the support frame. Other structures are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the left side of the lens frame slideway 8 of this embodiment is equipped with a first electronically controlled micro-drive mechanism 61, and the first electronically controlled micro-drive mechanism 61 is connected to the left side of the horizontal frame 3 through a flexible connector 71 , the first electronically controlled micro-drive mechanism 61 can drive the lens frame slideway 8 to move linearly in the vertical direction, and then drive the lens frame 1 and the lifting frame 4 to achieve linear motion in the vertical direction relative to the horizontal frame 3 . Other structures are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com