Light emitting diode encapsulation structure and light emitting diode encapsulation method

A technology for light-emitting diodes and packaging structures, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as the inability to meet diverse products, limit LED applications, etc., and achieve the simplification of packaging technology, and the improvement of luminous uniformity and consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

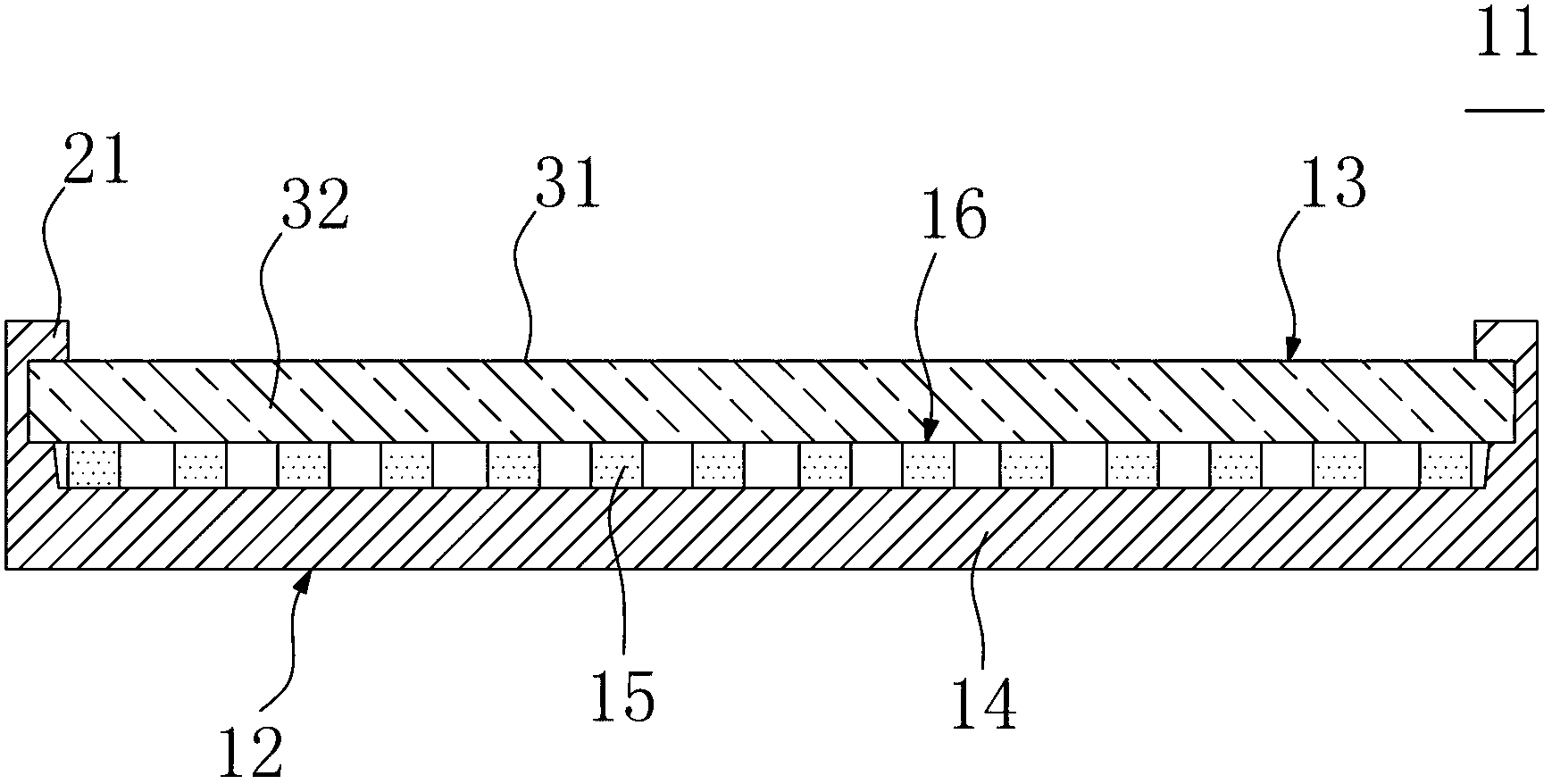

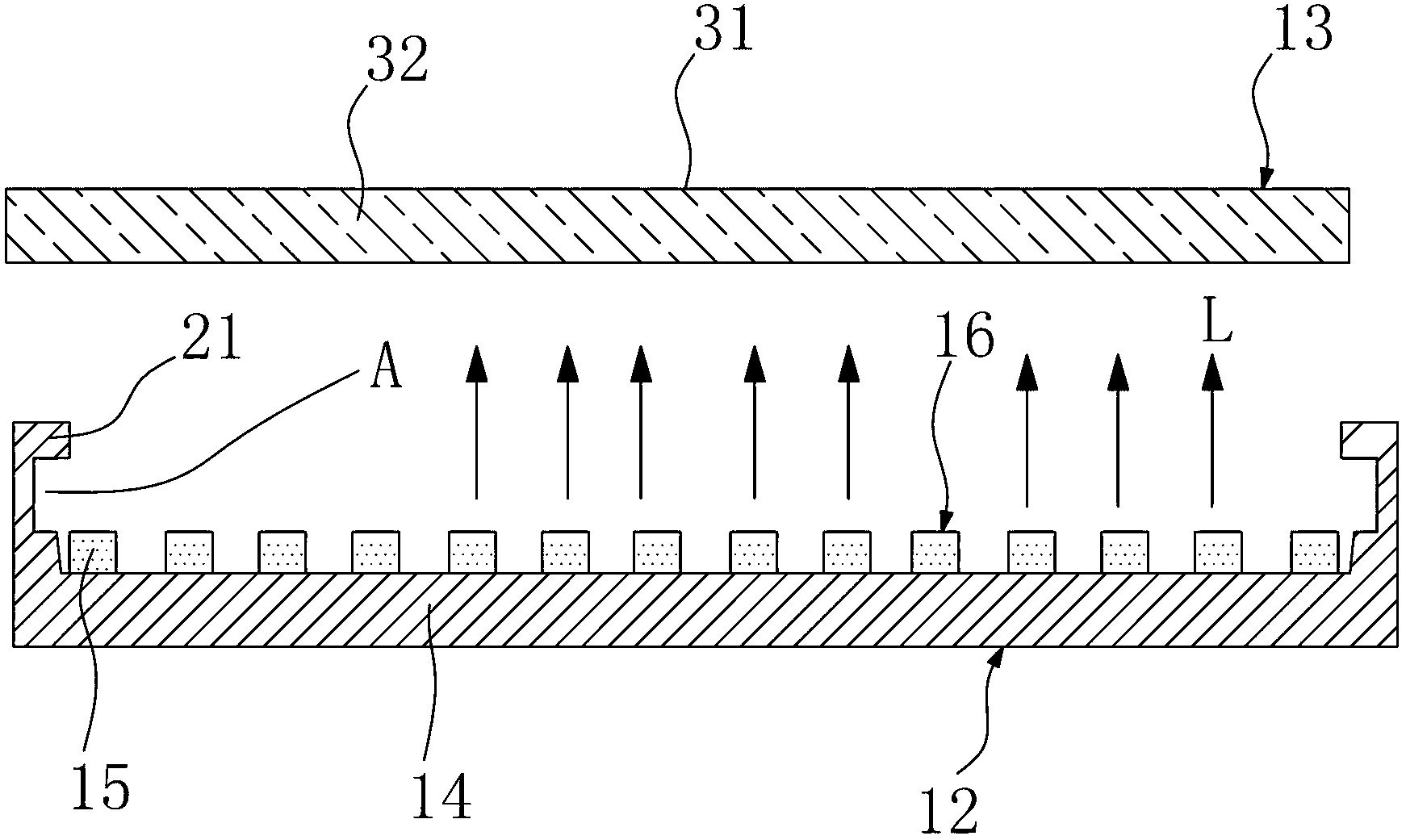

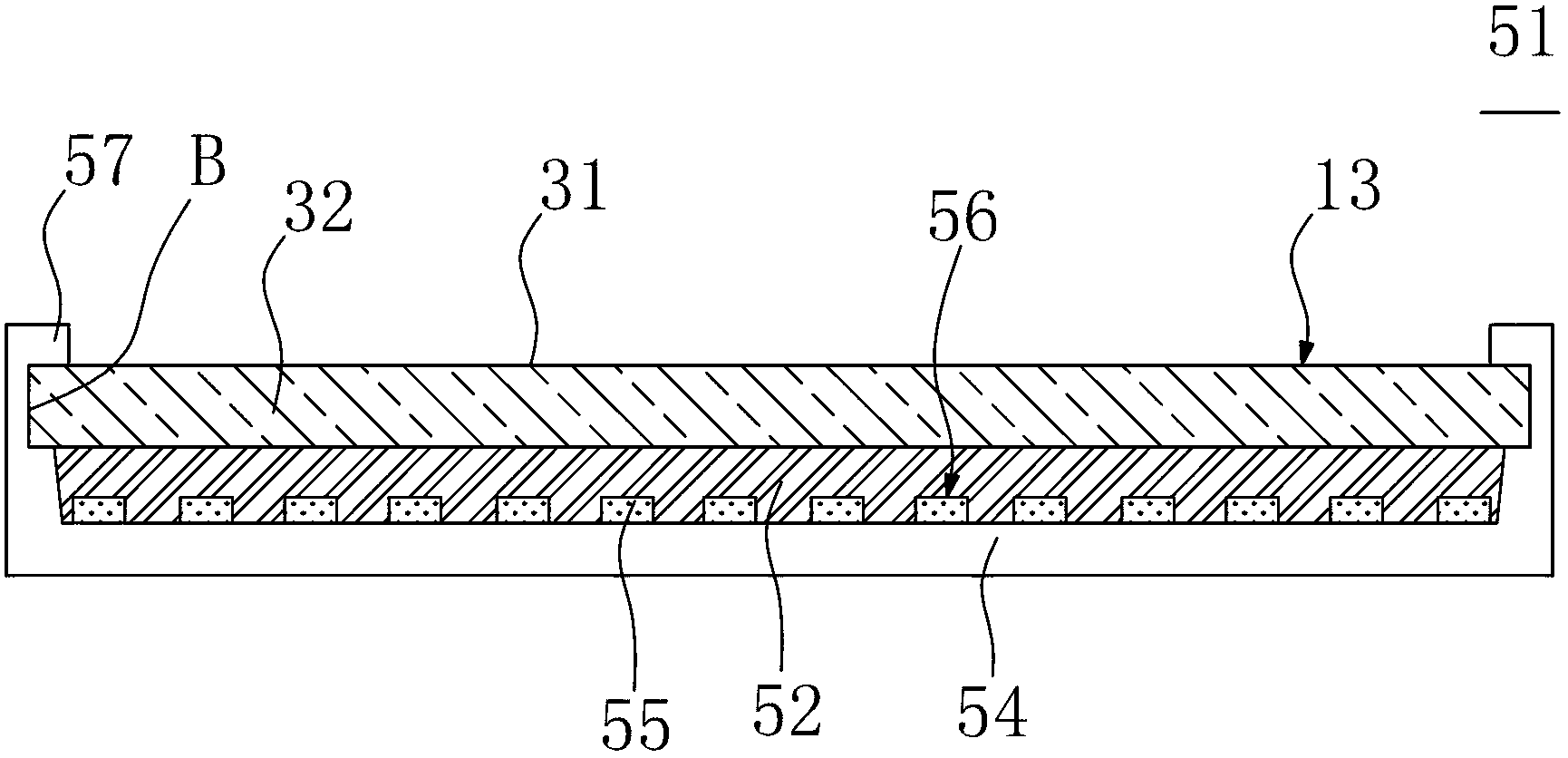

[0032] See figure 1 and figure 2 , figure 1 Shown is a schematic diagram of a first embodiment of a light emitting diode packaging structure according to the present invention, figure 2 shown as figure 1 The schematic diagram of the light-emitting diode packaging structure before packaging. The present invention provides a light emitting diode packaging structure 11, which can be used for backlight or lighting products. The light emitting diode packaging structure 11 includes a light emitting diode light bar 12 and a fluorescent transparent tube body 13. The LED light bar 12 includes a first substrate 14 and at least one LED 15 disposed on the surface of the first substrate 14, and the LED light bar 12 has a light-emitting surface 16, wherein the light-emitting surface 16 of the LED light bar 12 is also The light-emitting surfaces of these light-emitting diodes 15 . In contrast, the light-emitting diode 15 can have one or more light-emitting diode chips. The transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com